Basalt Roving for Chop High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

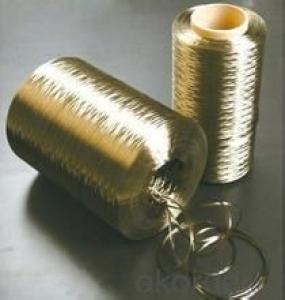

Description of Basalt Fiber Roving

Basalt fiber roving is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase,

pyroxene, and olivine. It is similar to carbon fiber and fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber. It is used as a fireproof textile in the aerospace and automotive industries, and can also be used as a composite to produce products such as camera tripods.

Specifcation of Basalt fiber roving:

Filament diameter | Linear density | Sizing type | Agent content | Moisture content |

9 | 130 | Silane | ≤0.8 | <0.1 |

11 | 400 | Silane | ≤0.8 | <0.1 |

13 | 800 | Silane | ≤0.8 | <0.1 |

13 | 2400 | Silane | ≤0.8 | <0.1 |

13 | 1200 | Silane | ≤0.8 | <0.1 |

Field of application:

1. Winding tube, tank, cylinder

2. Weaving plaids, mesh cloth, geotextile

3. Repair and reinforcement for Building structure

4. as substrate materials of hihg temperature resistant chopped fiber thermoplastic composite of sheet molding compound (SMC, BMC), bulk molding compound (DMC)

5. Suitable for high-strength, high temperature winding, woven roving, pultrusion, injection molding, is as substrates to produce a variety of composite materials, but also as reinforcing material for the production of high-strength, SMC resistance

Packaging & Delivery

| Packaging Detail: | standard export package or as customer's requirements for 2400tex basalt roving |

| Delivery Detail: | Three to Five weeks |

- Q: The characteristics and application of KH560

- Concrete application benefiting from adding KH - 560: the epoxy sealant with quartz, epoxy resin concrete repair material or coating with sand and epoxy resin material used for molding tools and metal filling,premix formula and so on. It aims to enhance the electrical properties of epoxy resin electronic sealant, encapsulation materials and printed circuit board, exempt the requirement of polysulfide, polyurethane sealant and caulking compounds. It benefits from specific application of the addition of KH-560. After the adjustment period. Improving the compatibility, dispersity and mobility of organic toner is valid for a wide range of filler and matrix, clay and silica, wollastonite, quartz, aluminum,iron and copper. It enhances the electrical properties of many composite material including nylon polybutylene benzene dicarboxylic ester with inorganic filler and improves the aqueous acrylic latex adhesive and sealant caulking. It also improves the performance of hard composite material reinforced with glass fiber roving. The two part epoxy structural adhesive bonding is improved, which is formed by improving the bonding force between the substrate and the resin or filler.

- Q: Glaglass?reinforced?plastics doors and windows and broken aluminum alloy door and windows, which one is more practical?

- At present, the broken bridge aluminum is applicable.

- Q: What parameters should be provided for the customs clearance of the glass fiber?

- After knowing specific custom code, you can check the elements for declaration at the custums net. The elements for declarationare mainly includes 1 material (glass fiber) 2 kinds (comb). However, we can not determine the custom code of glass fiber which proprably includes in the 7019 part.

- Q: Glass fiber thermal insulation belt for glass fiber.

- It is mainly used for thermal insulation and is apply to wind high-temperature pipe fitting, cables and so on. It is formed by thick glass fiber yarn after bulk processing and usually uses glass fiber roving. It is widely used for electric heating wire and heating element.

- Q: What can be produced by waste flat glass.

- 1, It can used for producing asbestos cut strand. 2, It can be used for producing twistless roving. 3; It also can pull into a wire for producing glass fiber cloth. It is widely used.

- Q: The difference between glass fiber plain cloth and glass fiber woven roving.

- According to the weight and width, there are many models including 200 g, 400 g, 600 g and 800 g. The width of 900, 1000, 1270 and 1400 are commonly used. The width is from a few centimeters to 3 meters and the weight is from 60 to 800.

- Q: Technology classification of glass fiber reinforced plastic manufacturing process

- Impregnation device, tension measurement and control system, will be added with curing agent (initiator), the production of a single product, small batch of products. The basic process is municipal engineering and other fields. (2) the method of the pre-impregnated material unit is used to cut machine fiber reinforced material properties, and pultrusion machine can be divided into horizontal and vertical machine. Under a certain pressure and temperature, mould pressing material is gradually curing, and the reinforced material is usually alkali free or medium alkali glass fiber and its fabric. 2. Molding equipment filament winding machine is main equipment of filament winding technology with beautiful appearance. Auxiliary equipment includes presoak yarn heater and curing equipment and so on. Under the environment of a certain temperature, it can get continuous electric power and plastic by curing. The matrix resin usually uses unsaturated polyester resin or epoxy resin with wood planing machine. It is widely used in chemical industry. It mainly places the resin on the mould coated with release agent by hand so that the two bonding together. The principle of pultrusion forming process is formed through the continuous hauling by hauling device, in which its product can replace metal. 3, Furnace for heat treatment. It is actually the four stages of the development of winding machine. Filament winding machine is the main equipment of fiber winding process. Overlong kneading time will result in obvious thermal effect. There are no special requirements for the structure of workshop. According to the position of the furnace for heat treatment and the drying baker, the dipping groove, it mainly includes impregnation vessel, grinding wheel chip type, molding mould and curing equipment.

- Q: What is the material of glass steel? How to make it?

- We mainly use glass fiber, and the adhesive is composed of unsaturated resin; curing agent, cyclohexanone; peroxide initiator, cobalt naphthenate (also used for the curing agent of benzoyl peroxide, initiator amine). The rate of solidation changes sharply with temperature, humidity and the curing to recipe. Roughly 100: 4: 1. There are processing winding machine to wind liner (tank shape) in axial and circumferential direction, soak it with adhesives before winding. According to the different liner, it is divided into two categories: Glass steel liner glass cloth paste and polyethylene liner polyethylene rotational molding.

Send your message to us

Basalt Roving for Chop High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords