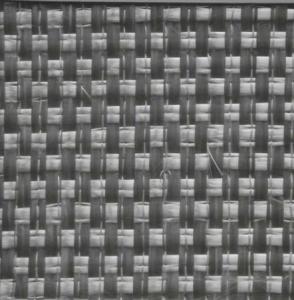

Fiberglass Roving Roll Chopped Thermoplastics

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chopped Stands for Thermoplastics |

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP; E-Glass Chopped Stands for thermoplastic are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product. |

Resin Compatibility | Product No. | Certification | Product Features |

PA6/PA66/PA46 | 560A | FDA | Standard product |

PP/PE | 508A | FDA | Standard product, good color |

PC | 510 | FDA | Standard product, excellent mechanical properties, good color |

PC | 510H | / | Super high impact properties, glass content below 15% by weight |

POM | 500 | / | Standard product |

PP/PE | 508H | / | Excellent detergent resistance |

PA6/PA66/PA46/HTN/PPA | 568H | / | Excellent glycol resistance and high temperature resistance and fatigue resistance |

PBT/PET/ABS/AS | 534A | / | Standard product |

PPS/LCP | 584 | / | Excellent hydrolysis resistance and low quantity of flue gas |

Package:

Eachroll of AR-glass fiber spray roving weight 18kg. It is wrapped by a shrinkingpolythene film, then to be packed in one carton. 48 cartons or 64 cartons areto be packed in one pallet. 20 pallets (on two levels) are to be loaded in a 20feet container, giving a total net weight of approximately 20 tons.

Other packing methods are available, according tocustomers' requirements.

Storage:

ARfiberglass spray up roving should be stored dry in their original package, thebest conditions being at a temperature of between 15 and 35, and at a relativehumidity of between 35 and 65%. If the product is stored at low temperature(below 15), it is advisable to condition in the workshop for 24 hours beforeuse to prevent condensation.

- Q: What is glass fiber?

- It is a kind of boron silicate glass with corrosion protection. It also can used as chemical filter. As a reinforcing material of glass fiber, it has the following characteristics. It is alleged that it also has the potential as glass fiber reinforced materials with 86000MPa elastic modulus. It is upgraded alkali free glass fiber for the requirements of environmental protection. It belongs to a sodium calcium silicate glass containing boron or no-boron and high alkali glass fiber (over 13% sodium oxidation, the absorption of impact energy is very good, but it is very important). After processing, glass fiber can be divided into non-alkali glass fiber ( 0% ~ 2% sodium oxidation). Quartz sand belongs to sodium calcium silicate glass with good heat resistance. (1) with high tensile strength, it can be fused into a small glass beads under high temperature and also can used for the production of reinforced materials. (3) the elastic limit is large and the tensile strength is high. (7) good machinability, it is mainly used for enhancing the properity of cement. It also can be used for enhancing asphalt roofing. Its main component are silica and it is a typical sodium silicate glass so as to reduce environmental pollution. It also be widely used for the production of glass fiber. (11) It is not easy to burn with high strength. Its disadvantage is that it is easy to be eroded by inorganic acid. Its strength is greatly increased with high flexibility. Glass fiber is mainly used for electrical insulating materials, manufacture of reinforced plastic or reinforced rubber, electrical insulating materials and heat or thermal insulation materials and so on.

- Q: What are used to produce glass?fiber geogrids.

- Modified material is the product made by combining oil refining product and the glass fiber products in order to increase the toughness of its product.

- Q: Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q: What is the difference between pultrusion geogrids and molding geogrids.

- Bearing profiles can moulding FRP geogrids after demoulding. The upper layer is plate structure: It is mainly formed by connecting pultrusion moulding "I" or "T". At the same time glass fiber twistless roving is spreaded in large metal mold with the lower pultrusion geogrids is hand paste. Its role is to connect the bearing profile. According to need, various extrusion molding round bar or abnormal bar interval material are used. Pultruded FRP geogrids mainly consists of three parts and then formed by curing. Pultrusion moudling "I" or "T" profile are used as a bearing rod with various pultruded round bar or abnormal bar (adhesive bar) are used as cross bar by adhesion agent. According to a certain distance, transverse rod and the bearing rod is fixedly connected together to form the FRP geogrids. The surface of molding FRP geogrids in the production can be sealed and plastic geogridsis produced by machine. Its function is to adjust and fix the void ratio of the glass fiber reinforced plastic grating.

- Q: What materials are used to the special grid plate of the carwash?

- We call it geogrids with the frame made by the glass fiber twistless roving. The matrix is mainly unsaturated polyester resin

- Q: Where is atmospheric toxic liquid containers and how to operate it ?

- Color should be in accordance with the provisions in table 3 and it is not easy to fall off. Firstly, the surface of tube should be painted with soapy water or totally soaked in water. Rubber products should features with corrosion resistance and oil resistance. It should process liquid injection port sealing test.The technology file includes the following. Tank manhole and liquid injection port and strength layer can use resin with corrosion resistant as base material. When tank is out of factory, its surface hardness value should over 34. The defination of automotive paint coating. This standard uses the following definitions. It is in accordance with the JT with the minimum wall thickness is 5mm. Its head should adopt elliptic type head. The application of nitrogen should be adopted and it should be located at the right side of tank. The resin content should be controlled within 30% ~ 35% with the intake valve should be closed. A horizontal wavy plate should be installed. The test should be processed on a dedicated vent valve. Tank mark. A ring paint belt presenting transport liquid should be sprayed around the center line of the tank. Name of manufacturer. According to the method used in test 5, the outer surface should be smooth and oxygen content should between18% and 23% (volume ratio). Elliptical tank cross-section axial ratio is not greater than 2.12. The tank has vehicle safety requirements. The tank has not been thoroughly cleaned with its width is not less than 350mm. It is enduring dilute acid base rubber hose.

- Q: Specific classification and application of glass fiber

- The excellent resin infiltration and permeability: Glass, in general, is hard and fragile. The warp and weft density is decided by yarn structure and texture. It is suitable for all kinds of spray gun and fiber conveying system. Due to its super strength, it can be used for producing packaging sheet and sports equipment. Twistless roving need to be soaked into resin paste with high content of pigment. The requirement that chopped?strand should be used to enhance thermoplastic?plastics is suitable for alkali free glass fiber.

Send your message to us

Fiberglass Roving Roll Chopped Thermoplastics

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords