Fiberglass Roving Mat Reinforced Basalt Fiber Rebar for Highway Engineering Basalt Composite Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Fiber Rebar for Highway Engineering Basalt Composite Bar

Introduction

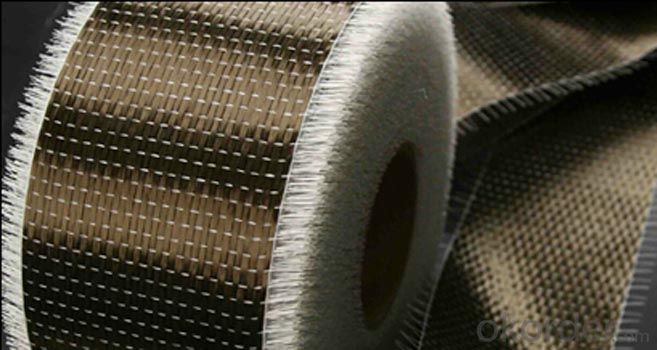

Basalt composite bar is similar to carbon fiber and fiberglass, but it has better mechanical properties and is lower in cost tah

Basalt composite bar is an ideal advanced material to replace steel and glass rebar. It can provide different size and apperance bars to meet clients demanding.Such as sand coated ,without sand-coated,rod,basalt rebar with steel core inside,which is widely used in the production of building components,in view of their high electro-insulating propertied ,basalt bars are used for making insulators for high -voltage power lines ,hydraulic engineering,concrete barriers,highlighting poles & seismic hazards.And rebar with cable in the core is new technology to supervise the condition of buildings,airports.tunnels,etc.

Property

1. Has a green environment-friendly performance

2. Alkali and radiation resistant

3. Fire-resistant and high-strength

4. Like fiberglass many products are made including yarn, mesh, geo-grid, roving, cloth, composite bar, chopped fiber, unidirectional cloth, fabrics, needled mats, Basalt Rebars, etc.

Applications

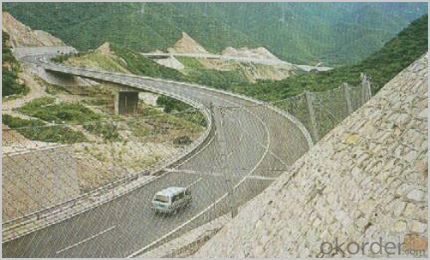

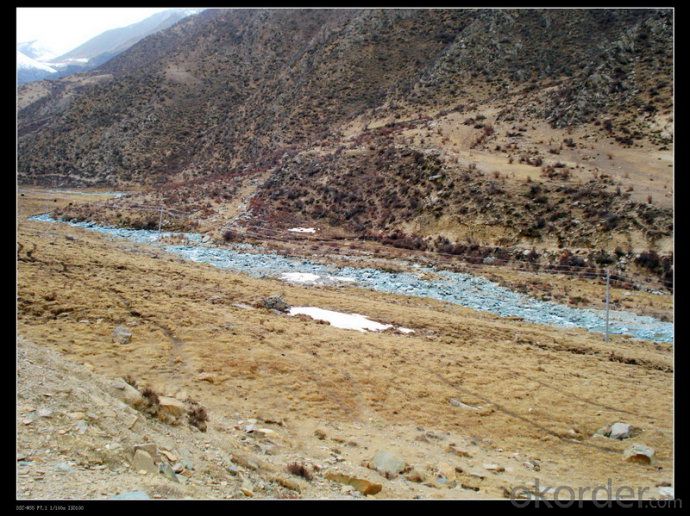

1, solve the north, south and humid areas and poor areas of acid-base environment, bridge, road corrosion resistance

of reinforced concrete structure issues, life issues;

2, solve the highway continuously reinforced concrete pavement construction technical problems and the need for welding

steel reinforced concrete structure of the problem;

3, reduce the weight of the bridge, to provide its carrying capacity and service life;

4, solution mining, tunnel, highway slope supporting the permanent anchor;

5, simplified construction difficulty, to improve construction efficiency, shorten the construction period and construction of

part of the cost savings;

6, lower construction cost and total project cost, and reduce maintenance costs.

Specification

Basalt Fiber Rebar | |||

Type | Nominal Diameter(mm) | Weight(g/m+-5%) | Coil length(m) |

BFRP-4 | 4 | 25 | 100-300 |

BFRP-6 | 6 | 56 | 100-300 |

BFRP-8 | 8 | 100 | 100-300 |

BFRP-10 | 10 | 158 | 100-300 |

BFRP-12 | 12 | 227 | 100-300 |

BFRP-16 | 16 | 405 | Piece length cut according to customer's requested |

BFRP-19 | 19 | 592 | |

BFRP-22 | 22 | 768 | |

BFRP-25 | 25 | 1076 | |

FAQ

1. How long will you get reply?

Any inquiry will be replied within 24 hours. Usually we will reply within 12 hours.

2. How long is warranty period?

We provide 3 year warranty period.

- Q: What are the main molding processing methods of plastics

- There are many methods of plastic forming. Six main forming methods are listed below: 1 injection molding and injection molding, extrusion molding. 2. extrusion molding, which is the main molding of thermoplastic plastic molding, 3 hollow blow molding, also known as the 4 compression molding also called compression molding. The upper and lower mold installation the template in the press on, the plastic material directly into the cavity, the mold is closed, full of plastic cavity in the heat and pressure, setting after plastic products. 5, injection molding and transfer molding. One of the main forming method is thermosetting plastics. It is feeding room, plastic pellets into mould in the heating, melting plastic under pressure through the pouring system of bottom mold transfer chamber fills the cavity, and then cure it. 6, solid molding molding plastics in melting temperature, in the molding process No obvious flow condition, for two times molding plastic sheet, such as vacuum molding, compression molding and air pressure molding, original for thin-walled parts molding, first used in the manufacture of thick wall parts. 7, other molding calendering, there are many casting plastic molding methods...

- Q: What can fiber concrete do?

- What can fiber in the fiber concrete do? 1, Improve the toughness of concrete; 2, Improve the flexural capacity of concrete; 3, Effective control of concrete cracking; 4, Appropriately increase the compressive strength of concrete; 5, Improve the impact resistance of concrete

- Q: What is sheaf packing in waste plastic industry?

- Polymethyl methacrylate Acrylic is also known as Acrylic and it is a combination of chemicals such as acrylic acid and methacrylic acid. It is often said that acrylic plate is polymethyl methacrylate (PMMA) plate which is combined by methyl methacrylate monomer.

- Q: Knowledges of bamboo fiber.

- The production process of bamboo fiber: bamboo, bamboo pulp, crude fiber - fiber carding - spinning - textile. Characteristics of bamboo fiber fabric is: antibacterial, high strength, healthy, moisture absorpotion, cooling, deodorization, kept warm, soft and comfortable. Especially suitable for infant clothing. It is a good choice.

- Q: What is the meaning of Glass fiber reinforced plastic purification tower ant medium

- raw materials and technical requirements of glass fiber reinforced resin purification tower production. Resin used in raw material resin manufacturing tower structure layer could be unsaturated polyester resin, epoxy resin, vinyl resin according to relevant requirements. According to the requirement by the supply and demand parties, both sides can choose other suitable winding resin after consulation. The resin used for corrosion resistant layer of the tower could be vinyl resin and epoxy resin according to relevant requirements. In accordance with the requirements of usage, they may also choose other resins with medium corrosion resistance after consultation. Unsaturated polyester resin should comply with the provisions of GB8237 and other resins shall comply with the corresponding standard. Generally speaking, resin should not contain pigments, dyes, fillers or colorants. Exception in the following circumstances: A) The materials we used does not interfere with the visual inspection of product quality and thixotropic agent does not affect corrosion resistance requirements of products ; b) if both parties agree, pigment, dye or colorant can be added into resin; c) if both parties agree, ultraviolet absorbent or flame retardant can be added into resin.

- Q: What does 3240 belongs to?

- 240 epoxy resin is used to produce glass fiber cloth by high temperature and pressure. It features with heat resistance and moisture resistivity. It is often used as components and parts for electrical appliance and electron with its model is 3240. It has high mechanical properties under medium temperature. Heat resistant grade is F (155 degrees). It is suitable for machinery with stable electrical performance at high temperature.

- Q: Which tensile strength of alkali resistant glass fiber mesh is bigger, the lateral one or longitudinal one?

- The weaving method is staggered. Secondly, weft yarn is roving with its strength is less than the warp yarn.

- Q: HS code for alkali-free glass fiber yarn

- The HS encoding the alkali-free glass fiber roving yarn is 70191200 and chopped yarn, spinning and Chinese HS EU tariff as follows, S and Z. Spun yarn is a spinning twist E-glass fiber. My question is whether it is yarn or spun yarn. If it is yarn, it would be twistless.

- Q: What kind of knife can used to cut glass wool cloth?

- You just need to cut off the big square. At first, you need to cut off the big square along border line and center line. Then you should cut off the two overlapping rectangles along the diagonal. At this moment, there are four right triangle which just can be put into a hollow square with its area just is equal to the small square, then you should put the small square into the hollow aquare.

- Q: What can glass fiber do?

- Glass fiber felt can be used in wide range. Glass fiber can also be used as a thermoplastic. Glass fiber can be used as glass fiber clothes, and made for thermosetting plastics.

Send your message to us

Fiberglass Roving Mat Reinforced Basalt Fiber Rebar for Highway Engineering Basalt Composite Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords