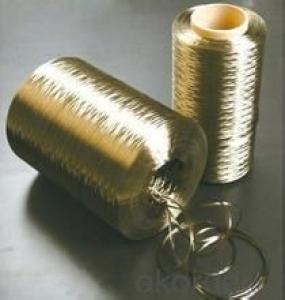

Fiberglass Roving for Sale - High Quality Basalt Assembled Roving with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

It is a Fiberglass roving produced by directly winding a certain number of individual fibers form the bushing without twist,it is coated with a silane-based size and is designed for reinforcing unsaturated polyester, epoxy,vinyl ester and phenolic resins. it is specially used to produce GRP pipes, pressure vessels, gratings and profiles and, when converted into woven roving, boats and chemical storage tanks, with filament winding, pultrusion and weaving process

Specifications

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns.

Rovings are manufactured according to Technical Specifications 5769-026-00204990-2005.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns. Complex yarns for assembled roving are made of basalt crumb.

Example of assembled roving: BC11320W-76(64)

B – raw material – basalt crumb.

C –continuous yarn.

11 – nominal diameter of a simple yarn, μm.

320 – nominal linear density of roving, tex.

W – purpose of roving: W – for weaving.

76 – type of silane sizing.

64 – nominal linear density of a complex yarn, composing roving.

Field of application:

1. Manufature of basalt fabrics;

2. Manufacture of basalt plastics;

3. Manufacture of bodies of rotation: pipes for chemical, oil and gas industries, pressure relief pipes, tanks (made by winding) for storage and transportation of chemically active substances, waterm combustive-lubricating products.

4. For reinforcement of plastics and concrete.

5. In production of geotextile nets and canvases, serving for reinforcing of asphaltic concrete pavement, by improving durability and split-resistance.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q: A chromic acid concentration and what kind of glass?reinforced?plastics should be used in chromic acid waste gas purification and recovery device.

- Rated condition is 2. * filtering grid should be cleaned regularly according to the degree of pollution. * according to different air volume. There are two types including vertical network format and horizontal network format. * Airflow direction of horizontal recycle collector is from right into the left, and chromic acid waste gas purification recoverer is mainly used for recycling and purifying chromic acid waste gas from electroplate chromate tank belt. * the bottom must be maintained at a level of 5 meters. *Face velocity passed through recoverer filter net must be maintained at 2 to 3 meters per second so that chromic acid can be expelled from bottom hole with efficency is over 90% and chromic acid liquid is recycled. * All air duct system before the recoverer is made from plastic plate. The chromic acid can be directly poured into the plating bath with the airflow direction cannot be reversed. The airflow direction of vertical collector is from bottom to top and it should be used together with BF4-72 type centrifugal ventilation machine. It can be cleaned once a month.

- Q: What are the advantages of glass fiber reinforced plastic antennas? What's the difference between an ordinary antenna and an ordinary one?

- SMC and its molded products as a new glass fibre reinforced plastics, glass steel, the processing methods can be divided into: hand molding, injection molding, paste pultrusion, winding molding, resin transfer molding, molding and other kinds of processing methods.

- Q: What's the difference between g;ass reinforeced plastics and ordinary glass?

- There are no difference and there are all glass fiber reinforced plastic!

- Q: grc fiberglass

- the content of ZrO2 in alkali resistant glass fibre whcih was used as reinforced material for portland cement is not less than 16. According to specific provisions in the T841, it is clearly required that alkali-resistant glass fiber must be used in GRC with its type incledes twistless roving.

- Q: What is glass fiber for?

- It is an excellent inorganic non-metallic materials with good insulation, good corrosion resistance and poor abrasion resistance. It have a great variety and produced by high temperature melting with glass ball or waste glass. It has high mechanical strength and can be used as electrical insulating materials and heat or thermal insulation. Each bundle fibers is formed by hundreds or even thousands of filaments with its diameter is from several microns to over twenty micron.

- Q: What are the causes and methods of glass fiber surface treatment?

- Pretreatment method: the surface treatment agent is added to the formula of glass fiber soakage agent, which is processed in drawing process (mainly used for roving and its textile products).

- Q: Fiber has the difference between twist and twist

- Twist refers to the twist of a single yarn in a single yarn or strand. The inclination of the single yarn from the lower right corner to the upper left is called "S twist". The twist from the lower left corner to the upper right is called the Z twist

- Q: Which tensile strength of alkali resistant glass fiber mesh is bigger, the lateral one or longitudinal one?

- The weaving method is staggered. Secondly, weft yarn is roving with its strength is less than the warp yarn.

- Q: How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

Send your message to us

Fiberglass Roving for Sale - High Quality Basalt Assembled Roving with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords