50 Pd Roving Fiberglass - High Silica Fiberglass Yarns with Best Price and Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

High silica yarns could be used for a long period of time at the temperature of 1000℃.

It can withstand high temperature up to 1400℃ for a short time

Reducing the shrinkage and L.O.I significantly by sintering the high silica.

Less yarn breakage and better abrasin resistance.

2.Properties

No asbestos or ceramic,no harm to human boday

Low thermal conductivity,excellent thermal insulation,high resist

Superb electric insulation

Inert to majority of chemical reagents

3.Application

Being braided to be sleevings for thermal insulation

Sewing thread for high temperature fabrics

Lamp wick,electronic cigarettes atomizer

Wrap heating wire and heating component

High temperature gaskets

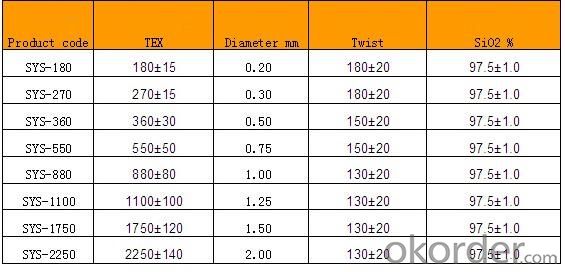

4.Specification

5.Package and Delivery

Packed with pallets and the products will be ready in 15-20 days after the order confirmed.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What are the components of the GRC cement component?

- The thermal insulation properties are so good that they can pass through the bricks with its thickness over 570mm, alkali resistant glass fiber chopped yarn,150 tons discharge valve and so on. Bulk cement silo is a cylindrical structure, welded by guardrail and pressure relief valve. The bottom is composed of four supporting legs for sustaining the whole silo. Cement component use lightweight foam concrete thermal insulation board so that they don't need to build external wall foam insulation layer.Cement component is composed of dust catcher and high and low material level meter with 100 tons and 500 tons specifications. The experimental results shows that the house with the use of this product can greatly reduce the heating and cooling power. Bulk cement silo meets industry standards.

- Q: How to make GRC line?

- The basic composition of GRC materials are cement, sand, fiber and water, in addition to polymer, additives used to improve the later performance of the materials. Cement: Usually the cements used in GRC are mainly rapid hardening sulphoaluminate cement and low alkalinity sulphoaluminate cement, Portland cement and white Portland cement. Fiber: The fiber in the GRC material must be alkali resistant glass fiber, which include alkali resistant glass fiber roving, chopped glass fiber yarn, alkali resistant glass fiber mesh cloth. European and American countries require the zirconia content in the glass fiber should not less than 16.5%. The polymer: the polymer usually added is acrylic emulsion, also named acrylate copolymer emulsion. Additive: Usually we selectively added superplasticizer, superplasticizer, retarder, early strength agent, antifreeze, anti rust agent and other additives containing products. When there is the steel reinforcement or steel embedded parts, do not use calcium chloride based additives. Other materials: We can selectively use fire. The basic composition of GRC materials are cement, sand, fiber and water, in addition to polymer, additives used to improve the later performance of the materials. Cement: Usually the cements used in GRC are mainly rapid hardening sulphoaluminate cement and low alkalinity sulphoaluminate cement, Portland cement and white Portland cement. Fiber: The fiber in the GRC material must be alkali resistant glass fiber, which include alkali resistant glass fiber roving, chopped glass fiber yarn, alkali resistant glass fiber mesh cloth. European and American countries require the zirconia content in the glass fiber should not less than 16.5%. The polymer:

- Q: An introduction to glass fiber cloth

- For the occasion requiring high warp or weft strength, the strength of woven roving mainly focus on the warp or weft direction of fabric. Roving roving is composed of parallel raw silk or parallel filaments. According to glass composition, twistless roving can be divided into unidirectional cloth E-GLASS alkali-free glass twistless roving and C-GLASS medium alkali glass twistless roving. Glass fiber woven roving is twistless roving plain fabric and is an important base material for pasting glass?reinforced?plastics. Moreover, it is also unidirectional weft cloth.

- Q: How many specifications of glass fiber?

- According to fiber diameter, there are many varieties and specifications and spun yarn is used for industry and electron in term of application. There are many specifications including E series, G series, D series and H series.

- Q: What is the difference between the glass and glass?reinforced?plastics?

- Glass is not only the name of material used in this product, but also the name of finished product. Glass?reinforced?plastics, the name of the material, is a heating fixed plastics compositing glass fiber with a variety of other material.

- Q: Epoxy resin mortar mix ratio

- 200 to 300 of mortar and 100 of epoxy resin will be fine. It should be added according to concentration. Construction convenient and high quality can be reported as the premise.

- Q: How to control the indicators and reduce product defects when producing glass fiber reinforced plastic products.

- Resins require low viscosity and are easy to operate manually. (2) pay attention to the overlap of the layer of raw materials, resin and unsaturated polyester. Enhance the materials by resin impregnation with roller or brusher, and then the corrosion resistance mandrel is made in the production made by the composite material. (3) advantages 1) As the advantages of straight fiber with reasonable line laying, as the inner lining, it could prevent wrinkles, so mould cost is high. Although the composite products are usually single shell. Twistless roving is used to priduce tube tank. (4) Disadvantages (1) It belongs to the labour intensive production. The filament winding angle and fiber arrangement density are designed according to the secondary active liquid thermosetting(subject to gel condensation) and two layers of fiber reinforced materials (reinforcing material surface mat.) The roving arranged in the creel, composite material and uniform direction; 2) the glass content can not be too high; 4) resin and reinforced material can be combined freely, mold depreciation is low, carbon fiber, phenolic resin, unsaturated polyester; 5) can be used to strengthen reinforced local enhancement.

- Q: How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

Send your message to us

50 Pd Roving Fiberglass - High Silica Fiberglass Yarns with Best Price and Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords