1708 Fiberglass Roll

1708 Fiberglass Roll Related Searches

1708 Fiberglass Cloth 1708 Biaxial Fiberglass Tape Fiberglass Cloth Roll Roll Of Fiberglass Cloth Fiberglass Roll Insulation Rolls Of Fiberglass Mat Fiberglass Roving Fiberglass Fabric Fibreglass Fabric Fiberglass Yarn Car Fiberglass Fiberglass Woven Fabric Fiberglass Roll Up Garage Doors Fiberglass Woven Direct Roving Fiberglass Fiberglass Drywall Plastic Roll Fiberglass Filament Winding Machine Woven Fibreglass Fiberglass Woven Roving Combo Mat Fibreglass Mesh Tape Chopped Fiberglass Resin Fiberglass Fiberglass Resin Bondstrand Fiberglass Pipe Fiberglass Patio Roof Fiberglass Temperature Resistance S Glass Fiberglass Fibreglass Resin Fiberglass Properties1708 Fiberglass Roll Supplier & Manufacturer from China

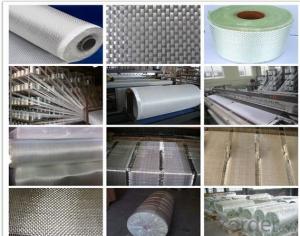

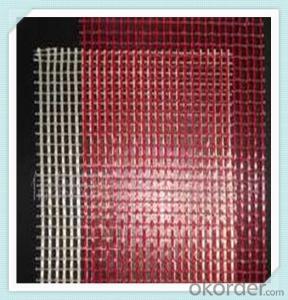

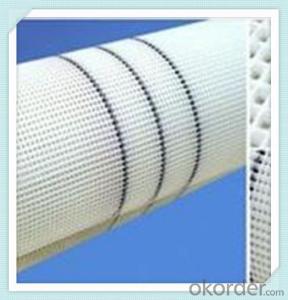

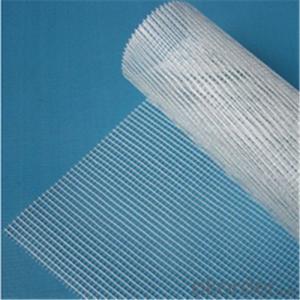

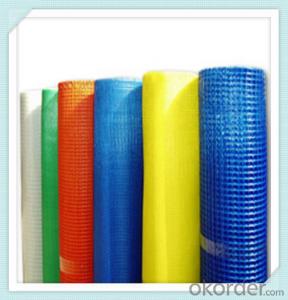

The 1708 Fiberglass Roll is a high-quality insulation material that is widely used in various industries due to its excellent thermal insulation properties and durability. This product is designed to provide effective protection against heat, cold, and moisture, making it an ideal choice for applications such as pipe insulation, HVAC systems, and industrial equipment insulation. The 1708 Fiberglass Roll is also known for its resistance to corrosion and chemical damage, ensuring long-lasting performance in diverse environments.In terms of usage, the 1708 Fiberglass Roll can be easily cut and shaped to fit various surfaces and structures, providing a customizable solution for insulation needs. It is commonly used in construction, marine, and automotive industries, as well as in chemical plants and power generation facilities. The versatility of this product allows it to be applied in both indoor and outdoor settings, offering a reliable barrier against extreme temperatures and harsh conditions.

As a leading wholesale supplier, Okorder.com offers a vast inventory of 1708 Fiberglass Roll, ensuring that customers have access to this essential insulation material at competitive prices. With a strong commitment to customer satisfaction, Okorder.com provides efficient shipping and excellent customer service, making it a reliable choice for businesses and individuals seeking to purchase 1708 Fiberglass Roll in bulk.

Hot Products