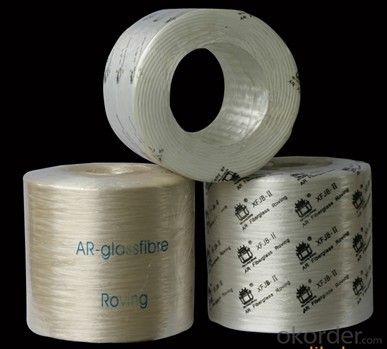

Fiberglass Woven Roving Mat - AR Spray Up Roving ZRO2 16.7%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of FRP Pipes

It is a Fiberglass roving produced by directly winding a certain number of individual fibers form the bushing without twist,it is coated with a silane-based size and is designed for reinforcing unsaturated polyester, epoxy,vinyl ester and phenolic resins. it is specially used to produce GRP pipes, pressure vessels, gratings and profiles and, when converted into woven roving, boats and chemical storage tanks, with filament winding, pultrusion and weaving process.

Specifications:

Glass Fiber Roving

Filament size:from 6mm~13mm

Tex count:550~2400tex

excellent dispersibility and alkali resistant

Applications:

beam,armrest,fence,and handrail, and it could be used in different industries like:Oil&Gas;Pulp&paper, Sewage water treatment;Power plant;Mining/refining;construction engineering;weaving and dyeing;pharmaceuticals;Food processing;Marine.

Packaging:

Cartons; pallets; customized packaging are welcomed

FAQ

1..Is your company a factory or trade company?

A:We have our own factory , we are on this business more than 10 years.

2.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

3.How long is the delivery time?

A:within 10-15 days after receiving deposit

- Q: What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q: What is the difference between pultrusion geogrids and molding geogrids.

- on many occasions. For example, glass?reinforced?plastics grating in carwash is generally used for holder or stand. Molded glass?reinforced?plastics grating is usually used for walkways, platforms, tree grate fence and so on. It is widely used in sewage treatment plants waste board and residential parking lot.

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: How to produce glass steel?

- Material: Glass cloth, resin, curing agent tool: Glass?pane or polyester i thin?film process: According to the specifications for glass?reinforced?plastics, glass plane or polyester i thin film should be prepared and then you should tail glass cloth in accordance with requirements. At first, you should compound resin, and then you should put cloth that already have been tailed on the glass pane and cover it with compounded resin until its thickness meets requirements after removing all bubbles in it. After that, you should continue to cover it with polyester i thin film without bubbles and put a piece of glass on it if you want it more neat. A new product is ready after taking off the glass fiber reinforced plastics and trimming it carefully.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: What does glass fiber operating tools do ?

- wire drawing,drying, winding, fabric and so on.

- Q: How many types of glass fiber and what is escorting yarn?

- According to the yarn bundle, it can be divided into roving, fine yarn and textile yarn. According to production types, it can be divided into direct yarn and union yarn. Yarn can be divided into twisted yarn and felting yarn according to the degree of twist. According to the manufacturing products, it is divided into winding yarn and twistless yarn.

- Q: Production process of glass fiber tube

- The tube is made in continuous movement of mandrel. It should be feed into steel mould fixed in bearing. After continuous filament winding and centrifugal casting process finishes,the number of pipe manufacturers using reciprocating fiber winding process is more than that of other two production technology. After the resin in products has been solidified, you should inject unsaturated resin with catalyst at the one side of steel mould. This process is that pipe passes through a feeding station whcih aims to supply resin presoak twistless roving. There are mainly three manufacturing techniques of glass fiber pipe. Reciprocating fiber winding technology (belonging to the fixed length method). The main material includes glass fiber reinforced materials and sand. Auxiliary angle (wingding angel) is controlled by the ratio of impregnating vessel movement speed and mandrel rotate speed. Pipe usually solidifies under high temperature. With the help of centrifugal force, its applicability is very good. Continuous filament winding process(belongs to continuous method). Impregnating vessel movement is controlled by computerization machine. With the number of the layers increases gradually, inner tube form a smooth plane due to the centrifugal force and mandrel gets out of glass?reinforced?plastics pipe. Centrifugal casting process (belonging to the fixed length method). Tube made in this way, is also known as glass fiber reinforced plastic sand pipe. Reciprocating filament winding process In this process

Send your message to us

Fiberglass Woven Roving Mat - AR Spray Up Roving ZRO2 16.7%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords