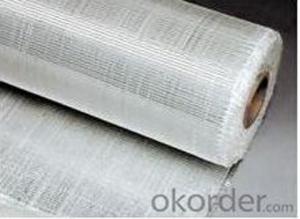

Fiberglass Unidirectional Fabric Cloth with Density 227gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 60000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Unidirectional Fabric Cloth with Density 227gsm

Description for Fiberglass Unidirectional Fabric Cloth with Density 227gsm

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Image:

Traits for Fiberglass Unidirectional Fabric Cloth with Density 227gsm

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: How does fiberglass mat tissue perform in terms of acoustic insulation?

- Fiberglass mat tissue performs well in terms of acoustic insulation. Its dense structure and ability to trap air make it an effective sound absorber, reducing the transmission of sound waves and minimizing noise pollution.

- Q: What are the factors that affect the diameter of electrospun nanofibers?

- High efficiency air filter, air filter (HEPA filter) is widely applied to the requirements of clean and sterile room (electronic goods and drug manufacturing sites, operation room) and other applications (such as air purifiers, vacuum bag filter and mask). Superfine glass fiber mat, melt blown (MB) fiber network, electrospun fiber mesh and ePTFE film and other media can reach...

- Q: Does fiberglass mat tissue require any maintenance?

- Fiberglass mat tissue does not typically require any maintenance once it has been installed. This material is designed to be durable and long-lasting, capable of withstanding various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance option for many applications. However, it is important to note that proper installation is crucial to ensure the longevity and effectiveness of fiberglass mat tissue. It should be installed according to manufacturer guidelines, ensuring that it is properly bonded and sealed to the surface. This will help prevent any potential issues or damage that may arise from improper installation. In some cases, fiberglass mat tissue may require occasional cleaning to remove any dirt or debris that may accumulate over time. This can be done using mild soap and water, or by following the manufacturer's recommended cleaning instructions. Overall, while fiberglass mat tissue does not require regular maintenance, it is important to address any issues or damages promptly to prevent further deterioration. Regular inspections and necessary repairs should be carried out to ensure the continued performance and longevity of the material.

- Q: Does fiberglass mat tissue require any special curing conditions?

- Yes, fiberglass mat tissue does require special curing conditions. It typically needs to be cured at specific temperature and humidity levels for a specific duration of time in order to achieve optimal strength and performance.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. Fiberglass mat tissue is a lightweight and cost-effective material that offers excellent thermal insulation properties. It can effectively regulate temperature and reduce heat loss, making it an ideal choice for hospitals where maintaining a comfortable and controlled environment is crucial. Additionally, fiberglass mat tissue is non-combustible and resistant to mold, ensuring a safe and hygienic environment in hospitals. Its durability and ease of installation also make it a practical choice for insulation in healthcare facilities.

- Q: Is fiberglass mat tissue resistant to fading?

- Yes, fiberglass mat tissue is resistant to fading.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue demonstrates excellent resistance to both mold and mildew. The material is inherently moisture-resistant, which prevents the growth of mold and mildew. Additionally, fiberglass is non-porous and does not provide a suitable environment for these microorganisms to thrive. Furthermore, fiberglass mat tissue is often used in applications where moisture is present, such as in bathroom walls or showers, and it has proven to be highly effective in preventing the growth of mold and mildew. Overall, fiberglass mat tissue performs exceptionally well in terms of mold and mildew resistance, making it a reliable choice for applications where these concerns are prevalent.

- Q: What is the weight range of fiberglass mat tissue?

- The weight range of fiberglass mat tissue can vary depending on the specific product and its intended application. Generally, fiberglass mat tissue can range in weight from around 20 grams per square meter (gsm) to 100 gsm or more. Thinner and lighter fiberglass mat tissues are often used for applications such as insulation or as a reinforcing layer in composite materials, while heavier fiberglass mat tissues are typically used for more demanding applications such as roofing or flooring. It is important to note that the weight range can also be influenced by factors such as the type of resin used, the desired strength or stiffness of the final product, and any specific requirements or specifications for a particular project.

- Q: Is fiberglass mat tissue suitable for railway rolling stock?

- Yes, fiberglass mat tissue is suitable for railway rolling stock. It offers excellent strength, durability, and fire resistance properties, making it a suitable material for various applications in the railway industry. Additionally, fiberglass mat tissue is lightweight, corrosion-resistant, and can be easily molded and shaped according to specific design requirements, making it an ideal choice for railway rolling stock components.

Send your message to us

Fiberglass Unidirectional Fabric Cloth with Density 227gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 60000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords