Fiberglass Mat Tissue from Italy Supplier - Fiberglass Unidirectional Fabric 350gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of E-glass Chopped Strand Mat

E glass chopped strand mat is made from fiberglass strands chopped to length and bonded together

with powder binder. Chopped strand mat is used primarily for hand lay-up processes, filament winding and press molding of FRP products. Typical products include bathroom

accessories, pipe, building materials, automobiles, furniture and other FRP products.

This products ischaracterized bg good combination of resin,easg operation ,good wet strengthretention,good laminate transparency

E glass chopped strand mat is made from fiberglass strands chopped to length and bonded together

with powder binder. Chopped strand mat is used primarily for hand lay-up processes, filament winding and press molding of FRP products. Typical products include bathroom

accessories, pipe, building materials, automobiles, furniture and other FRP products.

Features of E-glass Chopped Strand Mat

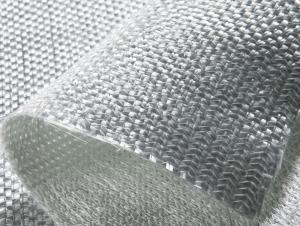

1.Warp and weft rovings aligned in a parallel,flat manner and uniform tension .

2.Densely alighed fibers,providing high dimensional stability ans easy handing .

3.Good moldability,fast and complete resin wet-out ,enabling high productively .

4.Good transporsision and hign strength of the composite products.

5.Even thickness ,no fuzz ,no stain.

6.Fast wet-out ,products with high strength ,little loss for strength in damp situation.

7.fiberglass woven roving has the features of : high tensile strength, corrosion resistance, flame retardance,insulativity.main function

8.applied to hand lay-up process

9.to reinforce UP resin

10.even thickness and flawless

11.good performance of processability in moulded parts

12.properties guaranteed under moisture condition

13.excellent mechanical strength during production of finished products

Features of E-glass Chopped Strand Mat

1.the composit products have high dry and wet tensile strenth and good transparency.

2.Low fuzz ,dirt ,impurity and other stain

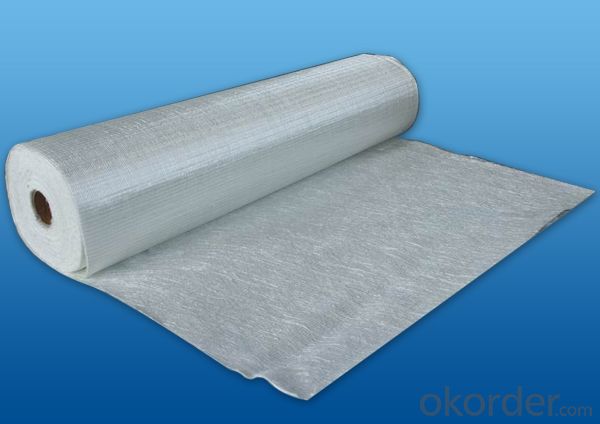

Images of E-glass Chopped Strand Mat

E-Glass Chopped Strand Mat Specification:

Property | Glass type | Weight(g/m2) | Width 200~3300 | Roll Weight | Moisture Content /% | Combustible Content /% | Breakage Strength /N |

Test Method | GB/T 1549 | ISO3374:2000 | ISO3374 | GB/T17470-1998 | ISO3344:1997 | ISO1887:1995 | ISO3342 |

EMC 80 | E-GLASS | 80±16 | ±5 | 6~50 | <0.2 | 13.6±0.35 | ≥200 |

EMC 100 | E-GLASS | 100±10 | ±5 | 6~65 | <0.2 | 9.5±0.35 | ≥170 |

EMC 150 | E-GLASS | 150±15 | ±5 | 6~97 | <0.2 | 8.0±0.35 | ≥40 |

EMC 225 | E-GLASS | 225±22 | ±5 | 6~150 | <0.2 | 5.0±0.6 | ≥60 |

EMC 300 | E-GLASS | 300±30 | ±5 | 6~180 | <0.2 | 4.0±0.6 | ≥90 |

EMC 450 | E-GLASS | 450±45 | ±5 | 6~180 | <0.2 | 3.8±0.6 | ≥120 |

EMC 600 | E-GLASS | 600±60 | ±5 | 6~240 | <0.2 | 3.6±0.6 | ≥150 |

EMC 900 | E-GLASS | 900±90 | ±5 | 6~190 | <0.2 | 3.4±0.6 | ≥180 |

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

- Q: Can fiberglass mat tissue be used for architectural facades?

- Yes, fiberglass mat tissue can be used for architectural facades. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in various construction applications, including architectural facades. It offers several advantages such as high strength, durability, weather resistance, and fire resistance. Additionally, fiberglass mat tissue can be easily molded into different shapes and sizes, making it suitable for architectural designs that require unique and intricate facades. Its versatility and aesthetic appeal make it a popular choice among architects and designers for creating visually appealing and functional facades.

- Q: What is the thickness range of fiberglass mat tissue?

- The thickness of fiberglass mat tissue may vary depending on the product and manufacturer at hand. Generally, one can find fiberglass mat tissues in thicknesses that span from 0.1mm to 1mm. It is worth emphasizing that the thickness of the fiberglass mat tissue plays a significant role in determining its strength, flexibility, and various other qualities. Therefore, it is imperative to carefully choose the suitable thickness that aligns with the intended application.

- Q: What are the potential limitations of using fiberglass mat tissue?

- Using fiberglass mat tissue comes with several potential limitations. To begin with, fiberglass mat tissue tends to be more brittle compared to other materials. This means that it may crack or break easily under certain conditions, especially if it is subjected to high levels of stress or impact. This brittleness can restrict its use in applications where durability and flexibility are important. Moreover, fiberglass mat tissue is not naturally resistant to moisture. If it is exposed to water or high humidity for extended periods, it can absorb moisture and lose its structural integrity. Consequently, it may not be suitable for use in environments where moisture resistance is crucial. In addition, working with fiberglass mat tissue can be challenging due to its sharp edges and fibers. Taking special precautions such as wearing protective clothing and using proper handling techniques is necessary to avoid injury. This can add complexity and cost to the use of fiberglass mat tissue in certain applications. Furthermore, cutting or manipulating fiberglass mat tissue can release fine particles or fibers into the air. Inhaling these particles can pose health risks, potentially leading to respiratory issues or irritation. To minimize these risks, it is essential to take proper safety measures such as using masks and ensuring adequate ventilation. Lastly, fiberglass mat tissue is relatively expensive compared to some alternative materials. Its production process involves multiple steps and specialized equipment, which contributes to higher costs. As a result, its use may be limited in applications where cost-effectiveness is a primary concern. In conclusion, while fiberglass mat tissue offers various advantages in terms of strength, insulation, and fire resistance, it is crucial to carefully consider its potential limitations before choosing it for a specific application.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Yes, fiberglass mat tissue is suitable for aerospace interiors. Fiberglass mat tissue is a lightweight and highly versatile material that offers excellent strength and durability. It is commonly used in aerospace applications due to its ability to meet stringent fire safety requirements, such as low smoke and toxicity emissions. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and temperature variations, making it an ideal choice for the demanding conditions inside an aircraft cabin. Its excellent sound insulation properties further enhance its suitability for aerospace interiors, ensuring a comfortable and quiet environment for passengers. Overall, fiberglass mat tissue offers a reliable and efficient solution for aerospace interior applications.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- The unique properties and advantages of fiberglass mat tissue make it widely used in the production of sports equipment. This material, made from fine glass fibers bonded together with a binder, is a non-woven fabric with a smooth texture. Despite being lightweight, it is strong and durable. In the manufacturing of sports equipment, fiberglass mat tissue is commonly used as a reinforcing layer. Its purpose is to enhance the strength and rigidity of the final product, making it more resistant to impact and stress. This is particularly important in sports equipment where durability and performance are crucial, such as surfboards, skateboards, snowboards, and tennis rackets. For instance, in the construction of a surfboard, fiberglass mat tissue is typically layered over a foam core and then impregnated with epoxy resin. This combination creates a structure that can withstand the forces exerted by the waves while remaining lightweight. Similarly, in snowboards and skateboards, fiberglass mat tissue is applied to the wooden core to provide additional strength and stiffness, which improves control and responsiveness. Furthermore, fiberglass mat tissue is also utilized in the production of protective gear like helmets and shin guards. By incorporating this material into the manufacturing process, these items can become more impact resistant and capable of absorbing shocks. This is particularly important in high-risk sports, as the fiberglass mat tissue acts as a protective layer, dispersing and diminishing the force of impacts. To summarize, fiberglass mat tissue is vital in the production of sports equipment as it reinforces structures, enhances strength and durability, and improves performance. Its lightweight nature and superior mechanical properties make it an ideal choice for various sporting applications, ensuring athletes can rely on their equipment to perform well while minimizing the risk of injury.

- Q: What is the maximum temperature resistance of fiberglass mat tissue?

- The maximum temperature resistance of fiberglass mat tissue typically ranges between 300-600 degrees Celsius, depending on the specific composition and quality of the material.

- Q: How does fiberglass mat tissue perform in terms of moisture resistance?

- Fiberglass mat tissue performs excellently in terms of moisture resistance. Its dense structure and composition make it highly resistant to water absorption, preventing moisture from seeping through and causing damage to the underlying material. This property makes fiberglass mat tissue an ideal choice for various applications where moisture protection is crucial, such as in the construction of roofs, walls, and insulation.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- The typical mechanical properties of fiberglass mat tissue include high strength, excellent tensile and tear resistance, good dimensional stability, and low elongation. Additionally, it has a high modulus of elasticity and is resistant to corrosion, chemicals, and moisture.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- PTFE itself has the effect of self lubrication, you can ask the production of PTFE can add these, should not be able to! Vespel can add graphite to increase self lubrication

- Q: What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The lifespan of fiberglass mat tissue in sports facility applications can differ based on various factors, including material quality, maintenance level, and usage conditions. However, fiberglass mat tissue generally has a lengthy lifespan and is recognized for its durability. When installed and maintained correctly, fiberglass mat tissue can endure for multiple decades. It is resistant to corrosion, rot, and degradation, making it suitable for use in sports facilities that face moisture, humidity, and other environmental factors. To ensure the longest lifespan for fiberglass mat tissue in sports facility applications, regular inspections, cleanings, and repairs may be necessary. Additionally, it is crucial to adhere to the manufacturer's recommendations for installation and maintenance to achieve optimal performance and longevity. It is important to note that despite its durability, fiberglass mat tissue may still experience gradual wear and tear, particularly in high-impact areas or facilities with heavy usage. In such cases, periodic replacements or repairs may be needed to maintain the material's integrity and functionality. All in all, fiberglass mat tissue is a dependable and long-lasting choice for sports facility applications. With proper care and maintenance, it can deliver exceptional performance and durability for numerous years.

Send your message to us

Fiberglass Mat Tissue from Italy Supplier - Fiberglass Unidirectional Fabric 350gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords