Fiberglass Mesh Fabric Roll for Construction e-glass Fiberglass Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

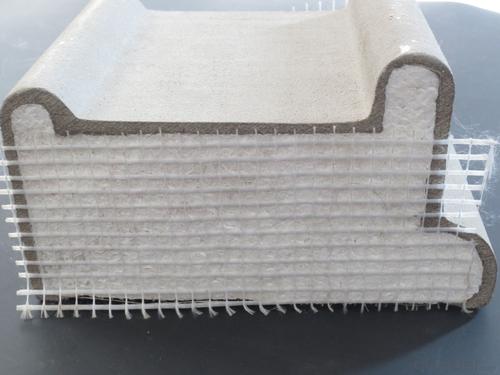

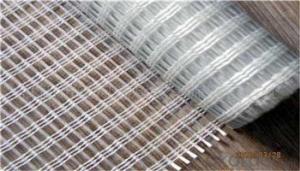

Alkali-resistant wall reinforced Fiberglass Mesh fiberglass manufacturer

Pass CE &ISO 9001

width can be 200cm

Firm mesh

The grid component

Fiberglass mesh is based on glass fiber woven fabric as substrate, the macromolecular

anti emulsion coating. It has good alkali resistance, flexibility and latitude to the high tensile

strength, with its good chemical stability, high strength, light weight, good dimensional

stability, strong impact resistance, pest control, fire protection, thermal insulation and

other features, welcomed by the user .

Use the grid cloth

Its widely used in: 1, wall reinforcing material; 2, reinforced cement products; 3, internal and

external wall insulation, 4, granite, marble, mosaic special mesh back paste network;

5, waterproof cloth, asphalt roofing; 6, reinforcing materials of plastics, rubber products;

7, fire board; 8, the grinding wheel base; 9, highway pavement with geogrid; 10, building

sealing tape etc.

- Q: Can fiberglass fabric be used for making carpet backing?

- Yes, fiberglass fabric can be used for making carpet backing. It is a commonly used material due to its durability, strength, and resistance to moisture. Fiberglass fabric provides stability and reinforcement to the carpet, making it suitable for high traffic areas.

- Q: How is fiberglass fabric used in the military industry?

- Fiberglass fabric finds various applications within the military industry due to its exceptional properties. One of the primary uses of fiberglass fabric in the military is for protective equipment and armor. The fabric is utilized to manufacture bulletproof vests, helmets, and body armor, providing soldiers with a lightweight yet strong material that offers excellent ballistic resistance. Additionally, fiberglass fabric is used for reinforcing and strengthening military vehicles and aircraft. It is commonly employed to reinforce the body of armored vehicles, including tanks and personnel carriers, increasing their resistance to explosions or other hostile actions. The fabric's high tensile strength and durability make it an ideal choice for this purpose. Furthermore, fiberglass fabric is utilized in the construction of military tents and shelters. Its lightweight nature, durability, and resistance to extreme weather conditions make it an excellent material for ensuring the protection and comfort of military personnel in the field. Moreover, fiberglass fabric is also employed for manufacturing communication and radar equipment enclosures. The fabric's electromagnetic transparency allows for efficient signal transmission and reception without compromising the safety or functionality of the equipment. This is crucial in military operations where reliable and secure communication is of utmost importance. In summary, fiberglass fabric is extensively used in the military industry for various purposes such as protective equipment, vehicle reinforcement, tent construction, and communication equipment enclosures. Its unique properties enable the military to enhance the safety, durability, and effectiveness of their personnel and equipment in combat situations.

- Q: Problems in making FRP models and models

- The higher precision is the three-dimensional engraving machine, but this machine can generally do very limited volume, can not do big things. This engraving machine usually needs to be polished again after making the bottom mold

- Q: Can fiberglass fabric be used for conveyor belts?

- Conveyor belts can indeed utilize fiberglass fabric. Renowned for its remarkable strength and ability to withstand heat, chemicals, and abrasion, fiberglass fabric proves itself suitable for diverse industrial uses, including conveyor belts. Given its capacity to endure extreme temperatures and maintain superb dimensional stability, fiberglass fabric becomes indispensable in conveyor belt systems that accommodate ceaseless motion and hefty loads. Furthermore, its minimal coefficient of friction facilitates seamless and efficient material handling. In summary, fiberglass fabric emerges as a dependable and robust option for conveyor belts in manufacturing, mining, and food processing industries.

- Q: Can fiberglass fabric be laminated with other materials?

- Fiberglass fabric possesses the capability to be combined with other substances through lamination. Lamination entails the act of uniting two or more layers of material in order to produce a composite material that boasts heightened properties. Fiberglass fabric frequently functions as a reinforcing material within laminates, granting them strength and endurance. It is feasible to laminate fiberglass fabric with diverse materials, including resins, plastics, metals, and alternative fabrics, to generate composite structures that possess particular characteristics. The lamination process generally entails the application of an adhesive or resin layer onto the fiberglass fabric, followed by bonding it with the desired substance. This process allows for the creation of adaptable and customizable materials that can be employed across a broad range of industries, such as aerospace, automotive, construction, and marine.

- Q: How does fiberglass fabric perform in vibration damping applications?

- Fiberglass fabric is renowned for its outstanding performance when it comes to applications involving vibration damping. The reason for this lies in its unique properties that make it an ideal material for absorbing and dissipating vibrations. To begin with, fiberglass fabric possesses remarkable tensile strength, which allows it to endure the forces exerted during vibrations without tearing or breaking. This ensures that it can effectively dampen vibrations over extended periods of time without experiencing wear and tear or a loss in its damping capabilities. In addition, fiberglass fabric boasts a high modulus of elasticity, which means it can resist deformation under stress. This property is crucial in vibration damping applications as it enables the fabric to absorb and dissipate the energy generated by vibrations, effectively reducing their intensity and preventing them from propagating to other components or structures. Moreover, fiberglass fabric is lightweight and flexible, enabling it to conform to various shapes and surfaces. This versatility is advantageous in vibration damping applications as it allows for easy installation and application of the fabric to different structures or components, guaranteeing efficient vibration reduction. Furthermore, fiberglass fabric exhibits exceptional thermal stability and resistance to chemicals, rendering it suitable for use in diverse environments. Whether exposed to high temperatures, moisture, or corrosive substances, fiberglass fabric maintains its damping capabilities, ensuring long-lasting and reliable performance. All in all, fiberglass fabric excels in vibration damping applications due to its high tensile strength, modulus of elasticity, lightweight and flexible nature, thermal stability, and chemical resistance. Its ability to effectively absorb and dissipate vibrations aids in noise reduction, prevents structural or component damage, and enhances overall performance and longevity.

- Q: Can fiberglass fabric be used for reinforcing plaster or stucco?

- Yes, fiberglass fabric can be used for reinforcing plaster or stucco. Fiberglass fabric is a strong and durable material that can provide additional strength and stability to plaster or stucco surfaces. It is commonly used as a reinforcement material in construction projects to prevent cracks and increase the overall durability of the plaster or stucco. The fiberglass fabric is typically applied to the surface before the plaster or stucco is applied, and it helps to distribute stress evenly, reducing the chances of cracking or crumbling. Additionally, fiberglass fabric is resistant to moisture and weathering, making it a suitable choice for exterior applications where plaster or stucco may be exposed to harsh environmental conditions. Overall, using fiberglass fabric for reinforcing plaster or stucco can enhance the structural integrity and longevity of the finished surfaces.

- Q: What are the different fiberglass fabric finishes for antistatic properties?

- Various fiberglass fabric finishes can be applied to provide antistatic properties. These finishes aim to reduce or eliminate the accumulation of static electricity on the fabric surface, which is crucial in industries like electronics, automotive, and aerospace. Some commonly utilized finishes include: 1. Carbon Coating: By applying a thin layer of carbon particles onto the fiberglass fabric, a conductive path is created, allowing swift dissipation of any static charge. 2. Conductive Polymer Coating: This finish involves applying a conductive polymer to the fabric, forming a continuous conductive network. The coating prevents static charges from accumulating and offers a high level of antistatic protection. 3. Metallic Coating: A thin layer of metal, typically silver or copper, is applied to the fiberglass fabric. The metal coating acts as a conductor, allowing static electricity to flow through and dissipate harmlessly. 4. Chemical Antistatic Finish: This finish entails applying a chemical treatment to the fabric surface. These treatments usually contain conductive agents that neutralize any static charge buildup. 5. Carbon Fiber Reinforcement: Carbon fibers can be woven into the fiberglass fabric to enhance its antistatic properties. Carbon fibers have inherent conductivity, effectively dissipating static charges. It is important to consider specific requirements when selecting a fiberglass fabric finish for antistatic properties. Factors such as the desired level of antistatic protection, durability, and intended use of the fabric will influence the choice of the appropriate finish.

- Q: What is the material of the computer mainboard PCB?

- The flat surface of the motherboard is a PCB printed circuit board which is divided into four layers and six boards. Four layers: main signal layer, ground layer, power layer and sub signal layer.

- Q: Is fiberglass fabric suitable for aerospace applications?

- Yes, fiberglass fabric is suitable for aerospace applications. It is known for its lightweight, high strength, and excellent thermal resistance, making it ideal for various aerospace components such as aircraft interiors, insulation, and structural elements. Additionally, fiberglass fabric has good resistance to chemicals and fatigue, further enhancing its suitability for aerospace use.

Send your message to us

Fiberglass Mesh Fabric Roll for Construction e-glass Fiberglass Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords