High Temperature Resistance Silica Chopped Fiberglass Fabric Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

It is high temperature resistant product.Mixed a ratio of organic fiber in the chopped silica fiberglass and put into fiberglass or stainless steel wire as reinforcement to spun the yarn,and then woven into the cloth.(stainless steel wire or fiberglass reinforced)

Application:

As the external insulation layer for industrial furnaces and other external heat preservation and heat insulation for a variety of mechanical equipment and pipeline;

As welding spark cloth for building,ship,large construction equipment industry;

Fireproof and heat indulation for rail vehicle,vehicle transportation insulation parts;

Can be processed into the fire-proof curtain in the building ,fireproof garment( covered aluminum),fireproof gloves,fireproof shoes,etc.

Product Capability:

SiO2>=96%;

Compared with the traditional high silica fiberglass cloth,the advantage of this cloth is that can be reinforced with stainless steel wire,have strong resistance performance,can be folded,thick and light weight,high air tightness;

The skin irritation is very small,no dust,can replace the traditional ceramic fiber cloth;

Higher temperature resistant,insulation,low heat conduction rate;

High thermal and chemical stability,good dielectric properties.

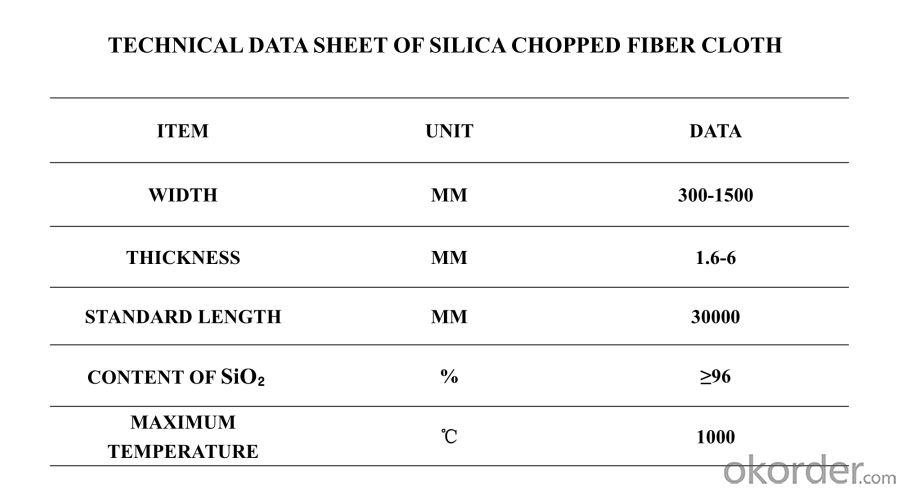

Data Sheet:

Silica fiber products:

A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q: How does fiberglass fabric perform in electromagnetic shielding?

- Due to its outstanding performance, fiberglass fabric finds wide usage in various applications for electromagnetic shielding. It possesses several key characteristics that contribute to its effectiveness in blocking or reducing electromagnetic interference (EMI) and radio frequency interference (RFI). To begin with, fiberglass fabric is a material that does not conduct electricity. This non-conductive property plays a crucial role in electromagnetic shielding as it prevents the transmission of electromagnetic waves through the fabric. Instead, the fabric acts as a barrier, reflecting and absorbing the electromagnetic energy. Furthermore, fiberglass fabric exhibits a high dielectric strength, indicating its ability to endure electric fields without breaking down. This characteristic ensures that the fabric can withstand intense electromagnetic fields without compromising its shielding effectiveness. Moreover, fiberglass fabric boasts a high tensile strength, rendering it durable and resistant to damage. This feature is vital for maintaining its shielding capability over time. Additionally, the fabric is resistant to chemicals, moisture, and extreme temperatures, guaranteeing that its performance remains unaffected by environmental factors. Another advantage of fiberglass fabric in electromagnetic shielding lies in its flexibility. The fabric can be easily shaped, molded, or applied to various surfaces, making it suitable for diverse applications. It can function as a lining in electronic enclosures, as a wrap for cables or wires, or even as a component in protective clothing for individuals working in high electromagnetic field environments. In conclusion, fiberglass fabric excels in electromagnetic shielding applications. Its non-conductive nature, high dielectric strength, durability, and flexibility make it an ideal material for blocking or reducing electromagnetic interference and radio frequency interference. Its widespread usage in various industries and its reliability in providing electromagnetic shielding establish it as a popular choice for numerous applications.

- Q: How does fiberglass fabric perform in compression strength?

- The compression strength properties of fiberglass fabric are typically good. Factors like fabric thickness, fiber type and quality, and the manufacturing process affect its ability to withstand compressive forces. To create fiberglass fabric, fine strands of glass fibers are woven together. These fibers are known for their high tensile strength, meaning they can resist stretching or pulling forces. While fiberglass is primarily recognized for its tensile strength, it also possesses a reasonable level of compression strength. When exposed to compression forces, fiberglass fabric can maintain its shape and resist deformation. It has a relatively high compressive strength compared to plastics or textiles. This makes it suitable for applications that require load-bearing capabilities, such as reinforcing concrete structures in the construction industry. The compression strength of fiberglass fabric can be further enhanced by using thicker fabric or increasing the density of glass fibers within the fabric. The manufacturing process also plays a crucial role in determining the final compression strength. Properly produced and treated fiberglass fabric can offer excellent durability under compressive loads. However, it is important to note that excessive compression forces can cause damage or failure in fiberglass fabric. Like any material, fiberglass has its limits, and surpassing these limits can result in permanent deformation or breakage. Therefore, it is essential to consider the specific requirements and load conditions of an application to ensure that the chosen fiberglass fabric can withstand the expected compression forces. In summary, fiberglass fabric generally exhibits good compression strength properties. It has reasonable load-bearing capabilities and can resist compressive forces without significant deformation or failure. Nevertheless, the specific compression strength of fiberglass fabric can vary depending on factors like fabric thickness, fiber quality, and manufacturing process.

- Q: Can fiberglass fabric be used for making filters for air purifiers?

- Fiberglass fabric is a great choice for creating air purifier filters due to its exceptional filtration properties. This material is highly effective at capturing and trapping airborne particles like dust, pollen, pet dander, and other allergens. By using fiberglass fabric filters, you can effectively eliminate these contaminants from the air, resulting in improved indoor air quality and a healthier living environment. Moreover, fiberglass fabric is both durable and resistant to high temperatures, making it perfect for long-lasting usage in air purifiers. However, it's important to be aware that when fiberglass is damaged or mishandled, it can release minuscule particles that may be harmful if inhaled. Therefore, it is crucial to handle and maintain fiberglass filters with caution to avoid any potential health hazards.

- Q: How is fiberglass fabric used in the production of fire-resistant blankets?

- Fiberglass fabric is used in the production of fire-resistant blankets as it provides excellent thermal insulation properties and is highly resistant to heat and flames. The fabric is woven using fine glass fibers that create a strong and durable material capable of withstanding intense heat. When used in fire-resistant blankets, fiberglass fabric helps to create a protective barrier that can shield individuals or objects from the dangers of fire, providing a crucial layer of safety and protection.

- Q: Do fiberglass fabrics have any electrical conductivity properties?

- No, fiberglass fabrics do not have any electrical conductivity properties.

- Q: Is fiberglass fabric resistant to UV degradation?

- Yes, fiberglass fabric is generally resistant to UV degradation. Fiberglass is made from fine glass fibers that are woven together to form a fabric. These glass fibers possess inherent properties that make them highly resistant to the harmful effects of UV radiation. UV rays from the sun can cause degradation and discoloration of many materials over time, but fiberglass fabric is designed to withstand prolonged exposure to sunlight without significant damage. The glass fibers in the fabric are not affected by UV rays, making fiberglass fabric a durable and long-lasting material for outdoor applications. However, it is important to note that prolonged exposure to intense UV radiation can still cause some level of degradation over an extended period. Therefore, it is recommended to take appropriate care and maintenance measures, such as regular cleaning and occasional application of UV protectant coatings, to ensure the longevity of fiberglass fabric in outdoor settings.

- Q: Can fiberglass fabric be used for making sports equipment?

- Yes, fiberglass fabric can be used for making sports equipment. Fiberglass is a versatile material that offers a range of benefits, such as being lightweight, strong, and durable. These qualities make it ideal for sports equipment that requires high-performance characteristics, such as surfboards, skis, and hockey sticks. Fiberglass fabric can be used to reinforce the structure of these items, providing added strength and rigidity while still maintaining a lightweight design. Additionally, fiberglass fabric can be easily molded into various shapes, allowing for customization and enhancing the performance of sports equipment. Overall, fiberglass fabric is a popular choice in the sports industry due to its versatility, strength, and ability to enhance the performance of sports equipment.

- Q: What is the weight of fiberglass fabric?

- The weight of fiberglass fabric may differ based on the particular type and thickness of the fabric. Typically, fiberglass fabric is quantified in ounces per square yard (oz/yd2) or grams per square meter (g/m2). Fiberglass fabric is typically available in weights ranging from 0.5 oz/yd2 (17 g/m2) to 3.0 oz/yd2 (102 g/m2) or beyond. Lightweight fiberglass fabrics are often employed in applications like reinforcement and lamination, whereas heavier fabrics find common use in structural reinforcement or insulation objectives.

- Q: Can fiberglass fabric be used for making soundproofing materials?

- Yes, fiberglass fabric can be used for making soundproofing materials. Fiberglass is an excellent material for sound insulation due to its high density and ability to absorb sound waves. When used in the form of fabric, it can be applied as a layer or wrapped around surfaces to effectively reduce noise transmission. Fiberglass fabric is commonly used in the construction industry for creating sound barriers in walls, ceilings, and floors. It is also utilized in automotive and aerospace applications to minimize noise pollution. The fabric's ability to trap and absorb sound waves makes it an ideal choice for soundproofing materials. However, it is important to note that proper installation and additional layers may be required to achieve optimal soundproofing results.

- Q: How is fiberglass fabric tested for quality assurance?

- To ensure the quality and performance of fiberglass fabric, rigorous testing is carried out using various methods during the quality assurance process. The tensile strength test is one of the primary tests conducted on fiberglass fabric. This test determines the fabric's ability to resist forces that attempt to pull it apart. Tensile testing machines apply controlled loads to the fabric until it breaks, allowing for the determination of its maximum tensile strength. This test is crucial for assessing the fabric's durability and suitability for applications that involve high stress or load-bearing requirements. Another important test is the tear strength test, which measures the fabric's resistance to tearing or propagating a tear. In this test, a sample of the fiberglass fabric is gradually torn apart by a constant force. The force required to tear the fabric provides insight into its toughness and ability to withstand tearing forces. This is particularly important in applications where the fabric may come into contact with sharp objects or abrasive conditions. Dimensional stability is also evaluated by subjecting the fiberglass fabric to extreme temperature variations and measuring its ability to maintain its shape and size. This test ensures that the fabric can withstand environmental conditions without shrinking or expanding. It is particularly crucial for applications that involve temperature fluctuations. In addition, fiberglass fabric undergoes tests to assess its resistance to chemicals, moisture, and UV radiation. Chemical resistance tests involve exposing the fabric to various chemicals and evaluating its reaction, ensuring its suitability for applications where it may encounter corrosive substances. Moisture resistance tests assess the fabric's ability to repel water and resist mold or mildew growth. UV resistance tests determine the fabric's ability to withstand prolonged exposure to sunlight without experiencing degradation or loss of mechanical properties. Furthermore, the flame resistance of fiberglass fabric is assessed through flame tests. These tests involve exposing the fabric to a controlled flame and measuring its ability to self-extinguish or resist burning. Flame-resistant fiberglass fabric is essential for applications where fire hazards are present, ensuring the safety of individuals and the protection of property. Overall, fiberglass fabric undergoes a comprehensive range of tests to ensure its quality and suitability for various applications. By evaluating properties such as tensile strength, tear strength, dimensional stability, chemical resistance, moisture resistance, UV resistance, and flame resistance, manufacturers can provide high-quality fiberglass fabric that meets the specific requirements of different industries and applications.

Send your message to us

High Temperature Resistance Silica Chopped Fiberglass Fabric Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords