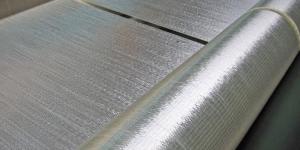

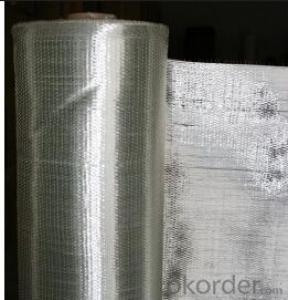

Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

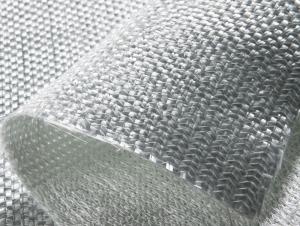

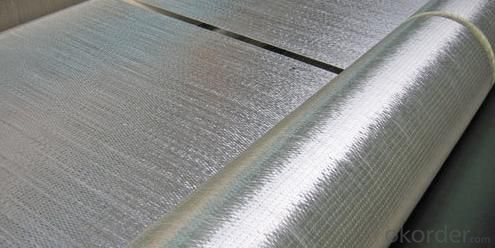

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.It is mainly used as reinforced materials in the composite material industry.

2.Properties

Fiber straight arranged, fiber strength be ultimately used.

No powder or emulsion, sink quickly, easy to operate.

Easy to design, high strength in one direction.

3.Technical Specification

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

4.FAQ

a. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

b. What is your MOQ?

Our MOQ is one pallet.

c. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

d. Payment terms?

We can accept L/C, T/T etc.

- Q: How is fiberglass mat tissue used in the production of windshields?

- The unique properties and functions of fiberglass mat tissue make it a crucial component in windshield production. To strengthen and increase the durability of the glass, manufacturers use fiberglass mat tissue as a reinforcement material. In the manufacturing process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering upon impact and holding it together for the safety of the vehicle occupants. By serving as a reinforcing material, fiberglass mat tissue improves the mechanical properties of the windshield. It enhances the impact resistance, reducing the likelihood of cracks or chips caused by stones, debris, or other objects. This reinforcement also provides structural integrity, allowing the windshield to withstand extreme weather conditions and vibrations without affecting its functionality. Moreover, fiberglass mat tissue aids in reducing noise transmission and vibrations. Its sound-damping properties contribute to a quieter and more comfortable driving experience by minimizing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue enables the production of curved windshields. The material's flexibility allows it to conform to different shapes and contours, enabling manufacturers to create windshields with customized designs and improved aerodynamics. In conclusion, fiberglass mat tissue plays a vital role in windshield production. Its reinforcement properties enhance the strength and impact resistance of the glass, ensuring the safety of vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: How does the roll length of fiberglass mat tissue affect its handling?

- The roll length of fiberglass mat tissue can have an impact on its handling. A longer roll length can make it more cumbersome and difficult to handle, especially if it is heavy. It may require more physical effort to transport and maneuver, which can slow down the installation process. On the other hand, a shorter roll length may be more manageable and easier to handle, allowing for quicker and more efficient use during installation. Ultimately, the roll length should be chosen based on the specific requirements of the project and the capabilities of the individuals handling it.

- Q: What is the specific gravity of fiberglass mat tissue?

- The specific gravity of fiberglass mat tissue typically ranges between 1.5 and 2.0.

- Q: Can fiberglass mat tissue be used for insulation in commercial buildings?

- Insulation in commercial buildings can be achieved using fiberglass mat tissue. This material is commonly utilized due to its exceptional thermal performance, durability, and cost-effectiveness. Typically composed of fine glass fibers bonded with resin, the mat can be applied to various surfaces such as walls and ceilings to enhance energy efficiency by minimizing heat transfer. Proper insulation is vital in commercial buildings to maintain a comfortable indoor environment and reduce energy usage. Fiberglass mat tissue offers numerous benefits for insulation purposes. It possesses low thermal conductivity, effectively resisting heat flow and diminishing heat loss or gain through the building envelope. This results in lower energy expenses and improved temperature control. Furthermore, fiberglass mat tissue is lightweight and easy to install, making it a convenient option for commercial buildings. It can be easily cut and shaped to fit around obstacles, ensuring a secure seal and preventing air leakage. This further enhances the effectiveness of the insulation. Moreover, fiberglass mat tissue is non-combustible, providing an added safety advantage in commercial buildings where fire protection is paramount. It does not contribute to the spread of flames and its fire resistance properties assist in containing fires and offering valuable escape time during emergencies. Overall, fiberglass mat tissue is a suitable and widely utilized insulation material in commercial buildings. Its thermal performance, ease of installation, and fire resistance make it a dependable choice for achieving energy efficiency and comfort in commercial spaces.

- Q: Can fiberglass mat tissue be used for flooring applications?

- Yes, fiberglass mat tissue can be used for flooring applications. Fiberglass mat tissue is a thin, non-woven fabric made from glass fibers. It is lightweight, flexible, and has excellent strength and durability. These properties make it suitable for various flooring applications. Fiberglass mat tissue can be used as a reinforcement layer in flooring systems, such as vinyl or linoleum flooring. It provides added strength and stability to the flooring, preventing it from cracking or warping over time. The mat tissue is typically embedded in a layer of adhesive or resin, creating a strong bond between the flooring material and the subfloor. Additionally, fiberglass mat tissue can be used as an underlayment for flooring installations. It acts as a barrier between the subfloor and the flooring material, providing insulation, soundproofing, and moisture resistance. This helps to protect the flooring from moisture damage, reduce noise transmission, and maintain a comfortable indoor environment. Overall, fiberglass mat tissue is a versatile material that can enhance the performance and longevity of flooring applications. Its strength, flexibility, and resistance to moisture make it a suitable choice for various flooring systems, providing added stability, durability, and comfort.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. Fiberglass mat tissue is a lightweight material that is commonly used for sound absorption and insulation purposes. It has excellent sound-absorbing properties and can effectively reduce noise levels in various applications, including acoustic panels. It is often used as the core material in acoustic panels to enhance their sound-absorbing capabilities. Additionally, fiberglass mat tissue is easy to work with, making it a popular choice for DIY acoustic panel projects. However, it is important to note that the effectiveness of acoustic panels also depends on other factors such as panel design, thickness, density, and installation method. Therefore, it is recommended to consult with experts or conduct thorough research to ensure that fiberglass mat tissue is the appropriate material for your specific acoustic panel needs.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Construction and other industries commonly use fiberglass mat tissue and mineral wool insulation as insulation materials. While both serve the purpose of providing thermal insulation, there are differences between them. Fiberglass mat tissue consists of bonded fine glass fibers that form a lightweight and flexible mat. This makes it easy to handle and install. It is also resistant to moisture, mold, and pests, making it a durable option. Its high R-value, which measures heat flow resistance, makes it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals like basalt, diabase, or slag. It is usually denser and heavier than fiberglass mat tissue. Mineral wool insulation has excellent fire resistance properties and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, it can absorb moisture, which may decrease its effectiveness over time. Both materials offer similar levels of insulation in terms of thermal performance. However, fiberglass mat tissue is slightly more efficient due to its higher R-value. Additionally, it is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between them depends on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is crucial to consider these factors and seek professional advice to determine the most suitable insulation material for a particular application.

- Q: How does the porosity of fiberglass mat tissue affect its performance?

- The porosity of fiberglass mat tissue directly affects its performance. Higher porosity allows for better resin absorption, resulting in improved bonding and strength of the fiberglass composite. Additionally, increased porosity enhances the mat's ability to trap and hold air, providing better insulation and soundproofing properties. Conversely, lower porosity may lead to insufficient resin penetration and weaker composite structures. Therefore, porosity plays a crucial role in determining the overall performance and functionality of fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used in automotive applications?

- Automotive applications can indeed make use of fiberglass mat tissue. This lightweight fabric, comprised of fine glass fibers, is frequently employed in the automotive industry for a range of purposes. These include reinforcing composite materials, enhancing mechanical properties, and decreasing weight. When it comes to automotive applications, fiberglass mat tissue is often utilized in the manufacture of fiberglass-reinforced plastics (FRP) components. These components encompass body panels, interior trim parts, engine covers, and various structural elements. By incorporating fiberglass mat tissue as a reinforcement layer during the production process, the strength, stiffness, and impact resistance of these components can be improved. Moreover, fiberglass mat tissue plays a vital role in reducing the weight of automotive parts while maintaining their structural integrity. This is of particular significance within the automotive industry, as reducing the weight of vehicles can result in heightened fuel efficiency and reduced emissions. In addition, fiberglass mat tissue boasts exceptional corrosion resistance, rendering it suitable for automotive applications that involve exposure to moisture, chemicals, and harsh environmental conditions. All in all, fiberglass mat tissue is a versatile material that can be effectively employed in a myriad of automotive applications. Its usage can enhance performance, reduce weight, and improve durability.

- Q: Glass fiber cotton or ceramic fiber paper insulation?

- Glass fiber cotton bar, there are more air inside, the effect may be better

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords