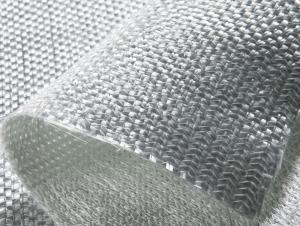

Fiberglass Mat Tissue Unidirectional Fabric 450gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Multiaxial Fabric-UD Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.Main Features of the Fiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ of Unidirectional

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is generally high due to the reinforcing properties of the fiberglass strands, which help to absorb and distribute impact forces.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as its quality, usage, and exposure to external conditions. Generally, fiberglass mat tissue is designed to be highly durable and long-lasting. When properly installed and maintained, it can typically last for several decades. However, it is important to note that fiberglass mat tissue can deteriorate over time due to environmental factors such as UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can accelerate the degradation process. To maximize the lifespan of fiberglass mat tissue, it is crucial to follow the manufacturer's guidelines for installation, maintenance, and periodic inspections. Regular inspections can help identify any signs of wear, damage, or degradation early on, allowing for timely repairs or replacements. It is recommended to consult with a professional or the manufacturer for specific information regarding the expected lifespan of a particular fiberglass mat tissue, as it can vary depending on the specific product and its intended application.

- Q: Does fiberglass mat tissue require any maintenance?

- Once installed, fiberglass mat tissue typically does not need any maintenance. This material is designed to be tough and long-lasting, capable of enduring various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance choice for many applications. Nevertheless, it is crucial to emphasize that proper installation is essential to ensure the longevity and effectiveness of fiberglass mat tissue. Following the manufacturer's guidelines, it should be installed in a way that securely bonds and seals it to the surface. This will help prevent any potential issues or damage that could result from improper installation. Occasionally, fiberglass mat tissue may require cleaning to remove accumulated dirt or debris. This can be achieved by using mild soap and water or by adhering to the manufacturer's recommended cleaning instructions. In summary, while regular maintenance is not required for fiberglass mat tissue, it is important to promptly address any issues or damages to prevent further deterioration. Regular inspections and necessary repairs should be conducted to ensure the material's continued performance and longevity.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: What are the different reinforcement densities available for fiberglass mat tissue?

- The different reinforcement densities available for fiberglass mat tissue can vary depending on the specific application and manufacturer. However, commonly used densities range from 15 grams per square meter (gsm) to 1000 gsm. Lower density fiberglass mat tissue, such as those in the range of 15-50 gsm, are often used for lightweight applications where strength and durability are not the primary concerns. These lower density mats are commonly found in areas like decorative surfaces, wallpaper, and lightweight insulation. Medium density fiberglass mat tissue, ranging from 50-300 gsm, offers a balance between strength and weight. This range is frequently used in various industries including construction, automotive, and marine. The medium density mats provide good reinforcement properties while still allowing flexibility and ease of handling. Higher density fiberglass mat tissue, typically above 300 gsm, is employed in heavy-duty applications that require high strength and superior durability. These mats are commonly used in areas like roofing, flooring, and composite manufacturing. The higher density provides enhanced mechanical properties and ensures the required structural integrity. Ultimately, the choice of reinforcement density for fiberglass mat tissue depends on the specific requirements of the application, including the desired strength, weight, and overall performance characteristics. It is important to consult with manufacturers and industry experts to determine the most suitable density for a particular use case.

- Q: What are the different quality standards for fiberglass mat tissue?

- There are several different quality standards that are used to assess the quality of fiberglass mat tissue. These standards are important for ensuring that the fiberglass mat tissue meets certain performance requirements and is suitable for its intended applications. One commonly used quality standard for fiberglass mat tissue is the ASTM D2178 standard. This standard specifies the requirements for fiberglass base materials used in the production of asphalt and coal tar roofing products. It includes criteria for the physical properties of the mat tissue such as weight, thickness, tensile strength, tear resistance, and permeability. Another widely recognized quality standard is the ISO 3376 standard. This standard provides guidelines for determining the tensile properties of nonmetallic materials, including fiberglass mat tissue. It specifies test methods for measuring parameters such as tensile strength, elongation at break, and modulus of elasticity. Additionally, the EN 1871 standard is often used for fiberglass mat tissue quality assessment in Europe. This standard specifies the requirements for reinforced bitumen sheets used in roofing applications. It includes criteria for the physical properties of the mat tissue and also covers aspects such as dimensional stability, resistance to heat, and resistance to aging. Furthermore, there are industry-specific quality standards that may apply to fiberglass mat tissue used in particular applications. For example, the ASTM C1666 standard is specific to fiberglass reinforced cementitious panels and establishes requirements for the materials used in their production. Overall, the different quality standards for fiberglass mat tissue aim to ensure that the material meets certain performance criteria, allowing it to be used effectively in various applications such as roofing, construction, and insulation. These standards provide a framework for manufacturers, suppliers, and customers to assess and compare the quality of different products in the market.

- Q: Can fiberglass mat tissue be used for insulation in shopping malls?

- Yes, fiberglass mat tissue can be used for insulation in shopping malls. It is a common and effective material for thermal insulation due to its low thermal conductivity and high resistance to heat transfer. Fiberglass mat tissue is also non-combustible, making it a safe option for commercial buildings like shopping malls. Additionally, it is lightweight, easy to install, and has excellent sound absorption properties, which can help in creating a comfortable and quiet environment within the mall. Overall, fiberglass mat tissue is a suitable choice for insulation in shopping malls, providing energy efficiency and improved indoor comfort.

- Q: Does fiberglass mat tissue provide good thermal conductivity?

- No, fiberglass mat tissue does not provide good thermal conductivity.

- Q: What are the different reinforcement patterns available for fiberglass mat tissue?

- There are several different reinforcement patterns available for fiberglass mat tissue, each offering unique benefits and characteristics. 1. Random Chopped Strand Mat (CSM): This is a widely used reinforcement pattern in fiberglass mat tissue. It consists of randomly chopped strands of fiberglass that are bound together with a binder. CSM provides good strength and stiffness properties, making it suitable for a wide range of applications. 2. Continuous Strand Mat (CSM): This reinforcement pattern consists of continuous strands of fiberglass that are evenly distributed and bound together with a binder. Continuous strand mat offers improved strength and stiffness compared to random chopped strand mat, making it ideal for applications that require higher performance. 3. Woven Roving: Woven roving is a reinforcement pattern that consists of interwoven bundles of fiberglass yarns. It provides excellent strength and impact resistance, making it suitable for applications that require high load-bearing capabilities. 4. Multiaxial Fabrics: Multiaxial fabrics are made up of multiple layers of fiberglass fibers that are oriented in different directions (usually at 0°, 90°, and ±45° angles). This reinforcement pattern offers balanced strength properties in multiple directions, making it ideal for applications that require isotropic properties. 5. Stitch-Bonded Fabrics: Stitch-bonded fabrics are made by mechanically stitching together layers of fiberglass fibers. This reinforcement pattern provides good drapability and conformability, making it suitable for applications that require complex shapes or curved surfaces. 6. Knitted Fabrics: Knitted fabrics are made by interlocking loops of fiberglass yarns. This reinforcement pattern offers excellent flexibility and ease of handling, making it suitable for applications that require conformability and flexibility. Each reinforcement pattern has its own advantages and is used in different applications based on the specific requirements of strength, stiffness, impact resistance, flexibility, or conformability. It is important to select the appropriate reinforcement pattern based on the desired end-use properties and manufacturing process.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Indeed, automotive applications can benefit from the utilization of fiberglass mat tissue. This versatile material finds extensive use within the automotive industry for a multitude of purposes. In particular, it serves as a reinforcement component for composite parts like bumpers, body panels, and interior elements. The exceptional strength and lightweight attributes of fiberglass mat tissue render it a prime selection for automotive applications, effectively augmenting vehicle performance and durability. Moreover, this material offers superb sound insulation and vibration damping properties, which are essential for enhancing comfort and reducing noise in automobiles. As a whole, fiberglass mat tissue stands as a dependable and widely adopted material across the automotive industry, playing a pivotal role in the creation of high-quality and efficient vehicles.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 450gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords