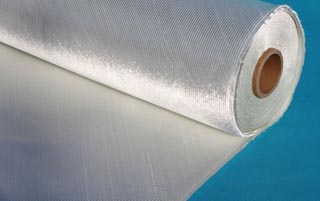

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 350gsm/50gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

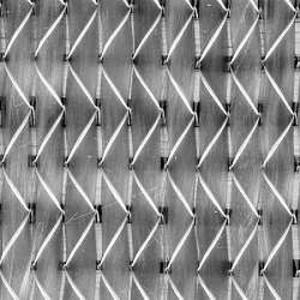

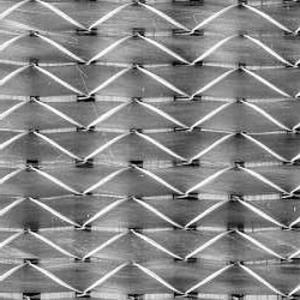

This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Feature | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Packaging: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Fiberglass mat tissue can be a suitable insulation material for cold storage facilities. Fiberglass is known for its excellent thermal insulation properties, which can effectively prevent heat transfer and maintain low temperatures in the storage area. Additionally, fiberglass is resistant to moisture and does not absorb water, which is important in cold storage facilities where condensation and moisture can be prevalent. The fiberglass mat tissue can be easily installed and provides a cost-effective solution for insulating the walls, ceilings, and floors of cold storage facilities. Overall, fiberglass mat tissue can effectively contribute to maintaining the desired cold temperatures and preventing any thermal leaks in these facilities.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: What is the typical width of fiberglass mat tissue rolls?

- The typical width of fiberglass mat tissue rolls can vary depending on the specific manufacturer and intended application. However, in the construction and insulation industries, fiberglass mat tissue rolls are commonly available in widths ranging from 1.22 meters (4 feet) to 2.44 meters (8 feet). These dimensions are often chosen to align with standard building materials and construction practices. It is important to note that there may be variations in width options depending on the region or supplier, so it is advisable to consult with the manufacturer or supplier for the specific width requirements for a particular project.

- Q: Does fiberglass mat tissue require any special precautions during storage?

- Special precautions are necessary when storing fiberglass mat tissue. Fiberglass is a delicate material that can easily be damaged if not stored correctly. Here are some precautions to keep in mind: 1. Maintain dry conditions: It is important to store fiberglass mat tissue in a dry, moisture-free environment. Excessive moisture can compromise its strength and integrity. 2. Avoid direct exposure to sunlight: The UV rays from sunlight can gradually degrade fiberglass. To prevent damage, store the material in a cool, shaded area away from direct sunlight. 3. Shield from dust and dirt: To maintain its effectiveness, fiberglass mat tissue should be stored in a clean, dust-free environment. Dust and dirt particles can become embedded in the material and reduce its efficiency. 4. Steer clear of extreme temperatures: Extreme heat or cold can also have an impact on the quality of fiberglass mat tissue. It is advisable to store it in an environment with controlled temperatures to prevent any potential damage. 5. Proper packaging: If the fiberglass mat tissue comes with packaging, it is recommended to keep it in its original packaging for added protection. If not, consider using a durable, moisture-resistant wrapping material. By adhering to these precautions, you can ensure that your fiberglass mat tissue remains in optimal condition during storage and is ready for use whenever necessary.

- Q: Can fiberglass mat tissue be used for aerospace applications?

- Indeed, fiberglass mat tissue proves to be suitable for aerospace applications. This lightweight and robust material finds extensive use in the aerospace industry for various purposes. It is frequently employed as a reinforcing material in composite structures, including aircraft wings, fuselages, and other components. The exceptional strength-to-weight ratio of fiberglass mat tissue makes it a favorable choice for aerospace applications, aiding in the reduction of overall aircraft weight without compromising structural integrity. Furthermore, fiberglass mat tissue exhibits resistance to corrosion and can withstand extreme temperatures, both of which are crucial considerations in aerospace environments. In conclusion, fiberglass mat tissue is a versatile material that meets the rigorous requirements of aerospace applications and is widely embraced within the industry.

- Q: Can fiberglass mat tissue be used for insulating windows?

- No, fiberglass mat tissue is not suitable for insulating windows. It is primarily used for reinforcing and strengthening surfaces, such as in the construction industry, and is not designed to provide thermal insulation.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue does provide some level of UV resistance. The resin used to bind the fibers in the fiberglass mat tissue helps protect it from the harmful effects of UV radiation. However, prolonged exposure to sunlight can still cause some degradation over time, so additional UV protection measures may be necessary for long-term durability.

- Q: Does fiberglass mat tissue require any special precautions during cutting?

- Yes, fiberglass mat tissue requires special precautions during cutting. It is important to wear protective clothing, gloves, and a respirator to prevent inhaling the fine fibers that can be released during the cutting process. Additionally, using a sharp blade or scissors is recommended to ensure clean cuts and minimize the risk of fraying or splintering.

- Q: Does fiberglass mat tissue have any fire-resistant properties?

- No, fiberglass mat tissue does not have inherent fire-resistant properties. However, it can be treated with fire-resistant coatings or combined with fire-resistant materials to enhance its fire resistance.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 350gsm/50gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords