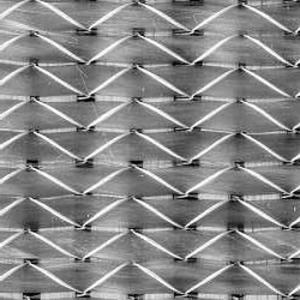

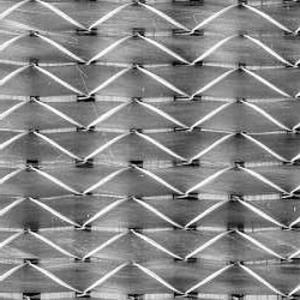

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 500/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. ◎ It’s compatible with UP, Vinyl Ester and Epoxy etc, used in GRP pultrusion process, hand lay-up process and RTM process etc, out-made products include GRP boats, automobile parts, wind energy blades etc.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1) which kind of glass fiber sample and materials can you provide?

We can provide the glass fiber and glass fiber down stream products samples of E glass, C glass, ECR glass, High alkali glass. The products includes single end roving, assembled roving for different applications( Piping, SMC, panel, winding mill plate) , chop strand for BMC, engineering plastic (PA, PPA, PPT, POM, etc), chop strand mat (from 100gsm-900gsm) for automobile and water tank, etc, woven roving (270gsm-800gsm), surface tissue (25-50gsm), multi-axial fabric of different unit weight.

2) Can you provide glass fiber composite material?

We can provide GFRP profile such as grating, T beam, U beam and other assembles pieces such as GFRP triangle frame, dust bin, fireplace, etc

3) How much sample can you provide and who will bear the sample cost?

We can provide the glass fiber samples not more than 1kg free of change. However, the courier cost must be born by the customer. As to the glass fiber composite materials, we can provide the piece not more than 1kg free of change ( with the existing module). However, the courier cost must be born by the customer. If we need to make a new model, this excludes.

4) How can you guarantee the quality?

We only provide the materials that have been approved by many customers and little claim or no claim on it. We have signed the obligation contract with the manufacturer. If the few quality issue happened, we can work with the manufacturer to solve it and customer’s benefit can be guaranteed.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Indeed, wind turbine nacelles can incorporate fiberglass mat tissue. This material, known for its lightweight and durability, finds wide application across various sectors, including the wind energy industry. Its exceptional mechanical properties, such as robustness, stiffness, and resilience against corrosion and fatigue, make it highly suitable for the nacelles of wind turbines. Moreover, fiberglass mat tissue possesses the capability to be easily shaped into intricate forms, rendering it an ideal choice for fabricating the complex components of wind turbine nacelles. In summary, the utilization of fiberglass mat tissue in wind turbine nacelles enhances their structural integrity, reduces their weight, and ultimately improves the overall performance and lifespan of the turbines.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a lightweight material that offers excellent thermal insulation properties. It can effectively trap heat and prevent it from escaping, making it suitable for creating insulation jackets that provide warmth and insulation.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Indeed, some degree of UV resistance is typically offered by fiberglass mat tissue. Comprised of glass fibers embedded in a resin matrix, this material provides a certain level of safeguard against UV radiation emitted by the sun. Nevertheless, it should be emphasized that the extent of UV resistance may differ based on the precise composition and manufacturing procedure of the fiberglass mat tissue. Furthermore, extended exposure to UV radiation can still result in gradual deterioration. Therefore, it is advisable to implement suitable measures, such as employing UV-resistant coatings or finishes, to augment the longevity and resilience of fiberglass mat tissue when utilized outdoors.

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue can vary depending on various factors such as the specific type of fiberglass mat tissue and its manufacturing process. However, in general, fiberglass mat tissue is known to have a relatively low moisture absorption rate. This is due to the hydrophobic nature of fiberglass, which means it repels water and is not easily permeated by moisture. As a result, fiberglass mat tissue is often used in applications where moisture resistance is important, such as in roofing materials, insulation, and automotive parts. While the exact moisture absorption rate may not be readily available without specific product information, fiberglass mat tissue is generally considered to be a moisture-resistant material.

- Q: Is fiberglass mat tissue suitable for oil and gas applications?

- Yes, fiberglass mat tissue is suitable for oil and gas applications. Fiberglass mat tissue is a lightweight, strong, and durable material that can withstand the harsh conditions commonly found in the oil and gas industry. It has excellent resistance to chemicals, including oil and gas, making it an ideal choice for applications such as pipeline insulation, tank lining, and filtration systems. Additionally, fiberglass mat tissue has low moisture absorption, good thermal insulation properties, and can be easily fabricated into different shapes and forms, making it a versatile material for various oil and gas applications.

- Q: Can fiberglass mat tissue be used for reinforcing swimming pools?

- Yes, fiberglass mat tissue can be used for reinforcing swimming pools. Fiberglass mat tissue is a strong and durable material that is commonly used in various construction applications, including swimming pools. It is lightweight, flexible, and resistant to water, chemicals, and corrosion, making it an ideal choice for reinforcing the structure of swimming pools. The fiberglass mat tissue is typically applied to the surface of the pool using a resin-based adhesive, creating a strong bond and enhancing the overall strength and stability of the pool. Additionally, the use of fiberglass mat tissue can help prevent cracking and improve the longevity of the swimming pool, making it a popular choice among pool builders and owners.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Residential buildings find fiberglass mat tissue to be a suitable option for insulation. This insulation material, made from glass fibers, is commonly used because of its exceptional thermal properties. With a high R-value, it effectively reduces heat transfer, keeping interiors warm in winter and cool in summer. In addition to its thermal efficiency, fiberglass mat tissue is renowned for its durability and long lifespan, making it a reliable choice. It resists moisture, mold, and pests, ensuring a healthy and comfortable living environment. Moreover, its lightweight nature and easy installation process make it efficient and cost-effective for insulation purposes. Moreover, fiberglass mat tissue possesses the crucial feature of being fire-resistant, which is highly desirable for residential buildings. It acts as a protective barrier, preventing the spread of fire and safeguarding occupants and property from potential hazards. Overall, fiberglass mat tissue is a popular and appropriate option for residential insulation due to its thermal efficiency, durability, fire resistance, and easy installation.

- Q: Can fiberglass mat tissue be used for insulating crawl spaces?

- Indeed, one can utilize fiberglass mat tissue to insulate crawl spaces. This material, widely employed for insulation objectives, proves to be versatile. It boasts a lightweight composition that enables flexibility and easy installation, rendering it appropriate for crawl spaces that typically present restricted access and cramped corners. Moreover, fiberglass mat tissue showcases resistance against moisture, mold, and pests, making it an optimal selection for crawl spaces that frequently encounter these complications. Adding to its appeal, it exhibits exceptional thermal insulation properties, thereby promoting steady temperature maintenance and energy efficiency within the crawl space. All in all, fiberglass mat tissue proves itself to be a dependable and efficient choice for crawl space insulation.

- Q: Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 500/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords