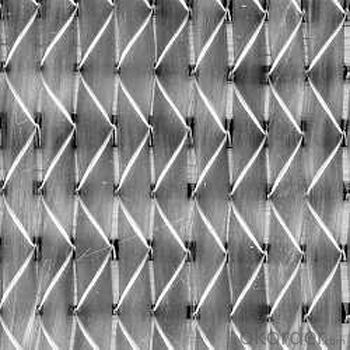

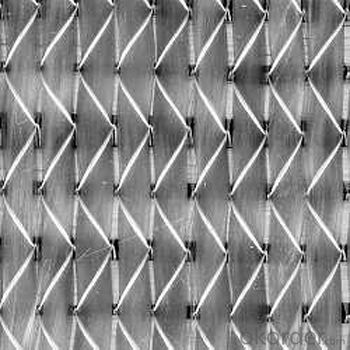

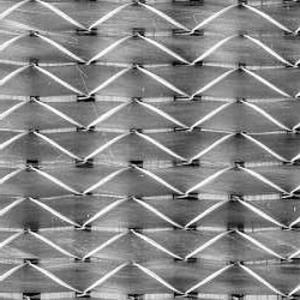

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 450/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

2. What is your MOQ?

Our MOQ is one pallet.

3. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

- Q: What are the common sizes available for fiberglass mat tissue?

- The common sizes available for fiberglass mat tissue can vary depending on the specific application or manufacturer. However, some common sizes include widths of 1 meter (39 inches), 1.27 meters (50 inches), and 1.52 meters (60 inches). The length of the fiberglass mat tissue can also vary, with common options ranging from 50 meters (164 feet) to 300 meters (984 feet) or more. It's important to note that these dimensions are just examples and may not reflect all available sizes on the market.

- Q: How does the weight of fiberglass mat tissue affect its performance?

- The weight of fiberglass mat tissue significantly affects its performance. The weight of the tissue refers to the amount of glass fibers per unit area. Generally, a higher weight indicates a higher concentration of fibers, which leads to improved strength and durability. Firstly, a heavier fiberglass mat tissue provides better tensile strength. The increased number of fibers in the tissue allows it to withstand higher levels of stress and strain without breaking or tearing. This makes it ideal for applications that require high load-bearing capacity, such as structural components in construction or automotive industries. Moreover, the weight of the tissue also influences its stiffness and rigidity. A heavier mat tissue offers better dimensional stability, meaning it will retain its shape and form even when subjected to external forces. This is crucial in applications where the material needs to maintain its structural integrity, such as in boat hulls or wind turbine blades. Furthermore, the weight of the fiberglass mat tissue affects its thermal and acoustic insulation properties. A higher weight typically correlates with better insulation capabilities, as the increased fiber density enhances the material's ability to trap air and reduce heat transfer or sound transmission. This makes it suitable for applications that require effective insulation, such as in buildings or industrial equipment. Lastly, the weight of the fiberglass mat tissue can impact its ease of handling and installation. A lighter tissue may be more flexible and easier to manipulate, making it simpler to fit into complex shapes or tight spaces. On the other hand, a heavier tissue might require additional support or equipment during installation. In conclusion, the weight of fiberglass mat tissue directly influences its performance characteristics, including tensile strength, rigidity, insulation properties, and ease of handling. Therefore, it is essential to consider the intended application and the desired performance requirements when selecting the appropriate weight of fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for aerospace applications?

- Yes, fiberglass mat tissue can be used for aerospace applications. It is commonly used as a reinforcing material in the aerospace industry due to its excellent mechanical properties, such as high strength-to-weight ratio and resistance to corrosion. Additionally, fiberglass mat tissue can provide thermal insulation and fire resistance, making it suitable for various aerospace components, including aircraft interiors, panels, and structural parts.

- Q: Can fiberglass mat tissue be used for insulating radiant floors?

- Indeed, insulating radiant floors is possible with the use of fiberglass mat tissue. This material, known for its exceptional thermal properties and moisture resistance, is widely favored for insulation purposes. Specifically engineered to enhance the strength and endurance of the insulation layer, fiberglass mat tissue effectively inhibits heat loss and enhances energy efficiency in radiant floor systems. By creating a shield between the heated floor and the colder ground or subfloor, it effectively prevents heat escape. Moreover, installing fiberglass mat tissue is hassle-free, as it can be easily tailored to fit any desired shape or size. This remarkable adaptability makes it a versatile option for insulating radiant floors.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Yes, fiberglass mat tissue can be used for insulation in chemical storage tanks. Fiberglass is known for its excellent insulation properties, making it a suitable material for insulating tanks that store chemicals. The fiberglass mat tissue is typically made from fine glass fibers that are woven together to create a strong and durable material. This mat tissue can be applied to the inner walls of the tank to provide insulation and prevent heat transfer. Additionally, fiberglass is corrosion-resistant and can withstand the harsh chemicals often stored in these tanks, making it an ideal choice for insulation in chemical storage tanks.

- Q: What is the moisture vapor transmission rate of fiberglass mat tissue?

- The moisture vapor transmission rate of fiberglass mat tissue can vary depending on various factors such as the specific composition of the material and its thickness. However, in general, fiberglass mat tissue has a relatively low moisture vapor transmission rate. This means that it has a relatively low ability to allow moisture vapor to pass through it. This characteristic makes it a suitable material for applications where moisture resistance is desired, such as in insulation or construction materials. However, it is important to note that the moisture vapor transmission rate of fiberglass mat tissue can be further influenced by other factors such as the presence of coatings or laminations, which may enhance or restrict its moisture vapor transmission properties.

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue generally performs well in terms of mold and mildew resistance. The material's non-porous nature and moisture resistance help inhibit the growth of mold and mildew. Additionally, fiberglass mat tissue is often treated with anti-fungal agents during the manufacturing process, further enhancing its resistance to mold and mildew. However, it is important to note that proper installation and maintenance are crucial to ensure optimal mold and mildew resistance.

- Q: Can fiberglass mat tissue be used for making lightweight partitions?

- Yes, fiberglass mat tissue can be used for making lightweight partitions. Its lightweight and flexible nature makes it an ideal material for constructing partitions that are easy to install and move, while providing adequate strength and insulation.

- Q: What is the shelf life of fiberglass mat tissue?

- The duration for which fiberglass mat tissue remains usable can differ based on various factors, including how it is stored, its packaging, and the recommendations of the specific manufacturer. In general, if stored in a cool and dry location without being opened, fiberglass mat tissue can maintain its quality for approximately one to two years. However, it is crucial to be aware that the material may deteriorate or lose its physical characteristics over time, which can impact its effectiveness and suitability for use. Consequently, it is recommended to consistently refer to the manufacturer's instructions or directly consult with them for the most precise information concerning the shelf life of a particular fiberglass mat tissue product.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Indeed, reinforcing concrete is possible with the utilization of fiberglass mat tissue. This lightweight and flexible material is frequently employed in construction endeavors to augment the sturdiness and endurance of concrete structures. By embedding it within the concrete, additional reinforcement is provided, which aids in averting the formation of cracks over time. Typically crafted from top-notch glass fibers that are interwoven to form a robust and steady substance, fiberglass mat tissue showcases exceptional tensile strength and corrosion resistance, rendering it an optimal selection for enhancing the performance of concrete. Whether employed in sidewalks, driveways, or other concrete formations, the presence of fiberglass mat tissue can substantially heighten the potency and lifespan of the concrete in question.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 450/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords