Fiberglass Mat Tissue Free Sample Offered Glass Wool Board/Glass Wool Insulation/Glass Wool Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

1) Heat-preservation and heat-insulation, sound absorption and noise reduction

2) Damp proof property

3) Excellent fire proof performance

4) Thermal stability, high temperature heat-stability, durability, high temperature shrinkage resistance

5) Non-poison, not contain rock wool and not grow the mould

6) Thin and long inner fiber

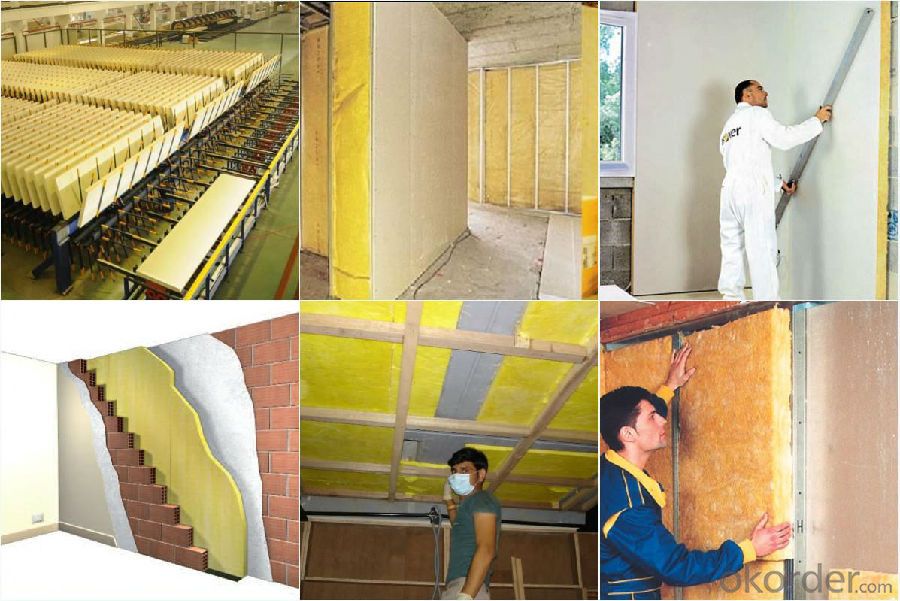

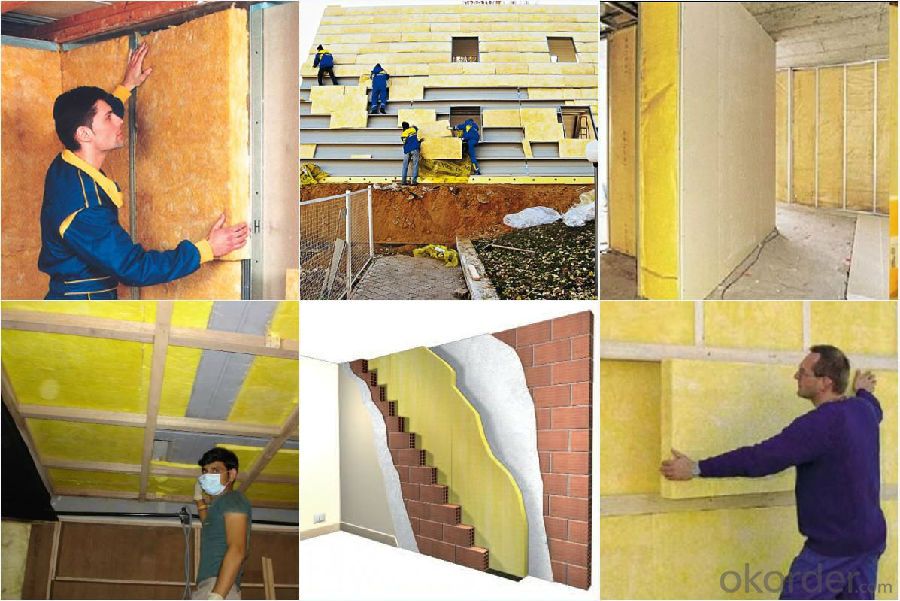

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue resistant to mold growth?

- Yes, fiberglass mat tissue is resistant to mold growth.

- Q: What are the different weights available for fiberglass mat tissue?

- Various industries, including construction, automotive, and marine, utilize fiberglass mat tissue extensively. This versatile material is available in different weights or thicknesses to meet various applications and specifications. The weight of fiberglass mat tissue is typically measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the available weights for fiberglass mat tissue range from approximately 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or higher. The weight of the tissue directly affects its strength, rigidity, and durability. For applications that require a high degree of flexibility and conformability, lightweight fiberglass mat tissue weighing around 30-50 gsm (1-1.5 oz/yd²) is commonly used. These lighter weight tissues are often employed in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, typically falling within the range of 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), strikes a balance between flexibility and strength. It finds frequent use in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are of utmost importance. For applications that demand exceptional strength and rigidity, heavyweight fiberglass mat tissue weighing between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more is ideal. This type of tissue is commonly employed in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are critical. It is important to recognize that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In certain cases, custom weights can be manufactured to meet unique project needs. In summary, fiberglass mat tissue is available in a range of weights to accommodate diverse applications. Selecting the appropriate weight is essential to ensuring optimal performance and long-term durability in various industries.

- Q: Can fiberglass mat tissue be used for corrosion-resistant coatings?

- Yes, fiberglass mat tissue can be used for corrosion-resistant coatings. Fiberglass mat tissue is a non-woven fabric made from fine fiberglass strands bonded together with a binder. It is commonly used as a reinforcement material in composite applications due to its high strength and corrosion resistance properties. When used in corrosion-resistant coatings, fiberglass mat tissue acts as a barrier between the substrate and the corrosive environment. It provides excellent resistance to chemicals, moisture, and other corrosive substances, protecting the underlying surface from degradation. Additionally, fiberglass mat tissue can be impregnated with various resin systems that enhance its corrosion resistance properties. These resin systems can provide additional protection against specific corrosive agents or environments, making the coating even more effective. Furthermore, the flexibility and moldability of fiberglass mat tissue allow it to conform to complex shapes and surfaces, ensuring complete coverage and protection against corrosion. Overall, fiberglass mat tissue is a reliable and effective material for corrosion-resistant coatings. Its high strength, corrosion resistance, and compatibility with various resin systems make it a suitable choice for protecting surfaces in corrosive environments.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. It is highly resistant to corrosion and chemicals, making it an ideal choice for such environments. Additionally, fiberglass mat tissue offers excellent thermal insulation properties, helping to maintain optimal temperature levels in the plant.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- The production of shower enclosures commonly utilizes fiberglass mat tissue due to its exceptional properties and advantages. This thin and flexible material consists of fine glass fibers that are randomly distributed and bonded together with a resin binder. To strengthen and enhance the shower enclosure, fiberglass mat tissue is primarily used as a reinforcement material. It is applied to the enclosure's surface to improve its strength, durability, and resistance to cracking or breaking. Initially, the fiberglass mat tissue is cut and sized according to the specific dimensions of the shower enclosure. It is then carefully placed or applied onto the enclosure's surface, typically through a process known as hand lay-up or spray-up. The mat tissue is strategically positioned to cover critical areas requiring reinforcement, such as corners, edges, and joints. Once the mat tissue is in position, a resin, usually polyester or epoxy, is applied over it. The resin penetrates the fiberglass mat tissue and bonds with the fibers, creating a solid and sturdy composite structure. This combination of resin and fiberglass provides additional strength and stability to the shower enclosure, making it more resistant to impact, stress, and water or humidity. Additionally, fiberglass mat tissue also contributes to the overall appearance of the shower enclosure. It helps achieve a smooth and uniform surface finish, eliminating imperfections and creating an aesthetically pleasing look. The mat tissue can be easily molded or shaped to match different designs and styles, enabling manufacturers to produce shower enclosures of various shapes, sizes, and patterns. In conclusion, fiberglass mat tissue plays a crucial role in the production of shower enclosures by offering reinforcement, strength, durability, and aesthetic benefits. This versatile material enhances the overall performance and visual appeal of the enclosures, ensuring they can withstand daily use and maintain their quality over time.

- Q: Does fiberglass mat tissue require any special precautions during handling?

- Yes, fiberglass mat tissue does require special precautions during handling. It is important to wear protective gloves, long sleeves, and a mask to prevent skin and respiratory irritation. Additionally, it is recommended to handle fiberglass mat tissue in a well-ventilated area to minimize the inhalation of dust particles.

- Q: Is fiberglass mat tissue suitable for agricultural applications?

- Certainly! Fiberglass mat tissue proves to be a suitable option for agricultural uses. Its versatility makes it an ideal material in the agricultural sector, providing numerous advantages. The resistance of fiberglass mat tissue to moisture, chemicals, and UV radiation makes it perfect for applications like greenhouse roofing, animal enclosures, and agricultural equipment. It possesses exceptional insulation properties, aiding in the regulation of temperature and safeguarding crops or livestock against harsh weather conditions. Moreover, fiberglass mat tissue is lightweight, easy to install, and long-lasting, making it an economical choice for agricultural projects. In conclusion, fiberglass mat tissue is a fitting material for a wide range of agricultural applications, ensuring durability, flexibility, and safeguarding for the farming industry.

- Q: Can fiberglass mat tissue be used for wind turbine blades?

- Yes, fiberglass mat tissue can be used for wind turbine blades. Fiberglass mat tissue is a lightweight and strong material that is commonly used in the construction of wind turbine blades. It provides excellent strength-to-weight ratio and is resistant to corrosion, making it ideal for withstanding the harsh environmental conditions that wind turbine blades are exposed to. Additionally, fiberglass mat tissue can be easily molded into complex shapes, allowing for the creation of aerodynamically efficient wind turbine blades. Overall, the use of fiberglass mat tissue in wind turbine blades helps to improve their performance and durability.

- Q: Is fiberglass mat tissue resistant to UV radiation?

- Yes, fiberglass mat tissue is resistant to UV radiation. Fiberglass is known for its excellent resistance to UV rays, making it highly suitable for outdoor applications. UV radiation from the sun can cause materials to degrade, discolor, or become brittle over time. However, fiberglass mat tissue is made with a special resin that provides UV stability, allowing it to maintain its strength and integrity even when exposed to sunlight for extended periods. This makes fiberglass mat tissue a popular choice for various outdoor applications such as roofing, boat construction, and exterior cladding, where it is essential to have a material that can withstand the damaging effects of UV radiation.

- Q: Is fiberglass mat tissue suitable for aerospace repairs?

- Yes, fiberglass mat tissue is suitable for aerospace repairs. Fiberglass mat tissue is a lightweight and flexible material that can be easily molded and applied to various surfaces. It is known for its high strength-to-weight ratio, making it ideal for applications where weight is a critical factor, such as aerospace repairs. Fiberglass mat tissue is commonly used in aerospace repairs to reinforce damaged or weakened areas of the aircraft structure. It provides excellent structural integrity and durability, ensuring the repaired area can withstand the extreme conditions and stresses encountered during flight. Furthermore, fiberglass mat tissue is compatible with various resin systems, including epoxy and polyester, allowing for efficient bonding and ensuring a reliable repair. Its versatility also enables it to be used in both interior and exterior repairs, such as repairing composite panels, reinforcing wing sections, or repairing damaged fuselage areas. In addition to its mechanical properties, fiberglass mat tissue also exhibits excellent resistance to corrosion, moisture, and chemicals, enhancing the longevity of the repaired components. This is particularly crucial in aerospace applications, where the aircraft is exposed to harsh environmental conditions. Overall, fiberglass mat tissue is a suitable material for aerospace repairs due to its lightweight, high strength, versatility, and resistance to environmental factors. Its use in the aerospace industry has been well-established, and it continues to be a reliable choice for repairing and reinforcing critical aircraft components.

Send your message to us

Fiberglass Mat Tissue Free Sample Offered Glass Wool Board/Glass Wool Insulation/Glass Wool Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords