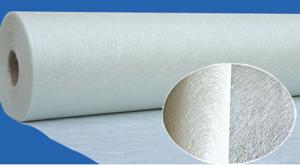

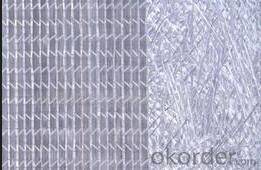

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1700gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Main Features of the woven roving combo mat

Fiber level unfolded without cross, high density, high utilizing rate.

Multi-layer finished one time, decrease layer and enhance efficiency.

Woven Roving Combo Mat Specification

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for corrosion-resistant applications?

- Yes, fiberglass mat tissue can be used for corrosion-resistant applications. It is commonly used as a reinforcement material in composite products that require resistance to corrosion, such as pipes, tanks, and structural components in harsh environments. The fiberglass mat tissue provides strength and durability while also enhancing the corrosion resistance properties of the final product.

- Q: Does fiberglass mat tissue require any maintenance?

- Fiberglass mat tissue does not typically require any maintenance once it has been installed. This material is designed to be durable and long-lasting, capable of withstanding various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance option for many applications. However, it is important to note that proper installation is crucial to ensure the longevity and effectiveness of fiberglass mat tissue. It should be installed according to manufacturer guidelines, ensuring that it is properly bonded and sealed to the surface. This will help prevent any potential issues or damage that may arise from improper installation. In some cases, fiberglass mat tissue may require occasional cleaning to remove any dirt or debris that may accumulate over time. This can be done using mild soap and water, or by following the manufacturer's recommended cleaning instructions. Overall, while fiberglass mat tissue does not require regular maintenance, it is important to address any issues or damages promptly to prevent further deterioration. Regular inspections and necessary repairs should be carried out to ensure the continued performance and longevity of the material.

- Q: Can fiberglass mat tissue be used for waterproofing?

- Yes, fiberglass mat tissue can be used for waterproofing. Fiberglass mat tissue is a thin, non-woven material that is made from fiberglass fibers. It is commonly used in construction and building applications to provide reinforcement and waterproofing properties. When applied with a waterproofing agent or resin, the fiberglass mat tissue can create a waterproof barrier that helps to prevent the passage of water or moisture. This makes it an effective choice for applications such as roofing, basement waterproofing, and bathroom or shower installations. The strength and durability of fiberglass mat tissue also make it resistant to cracking or tearing, ensuring long-lasting waterproofing protection.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue varies depending on its specific composition and the standards to which it has been tested. Fiberglass mat tissue is typically designed to have fire-resistant properties, but the exact fire rating will depend on factors such as the thickness of the tissue and any additional fire retardant coatings or treatments that have been applied to it. To determine the fire rating of a specific fiberglass mat tissue product, it is best to consult the manufacturer's specifications or test reports, as they will provide the most accurate and up-to-date information.

- Q: How does fiberglass mat tissue perform in terms of moisture resistance?

- Renowned for its exceptional resistance to moisture, fiberglass mat tissue is composed of tightly woven strands of fiberglass that form a formidable barrier against the infiltration of water. This remarkable feature renders it highly efficient in thwarting the permeation of water or moisture, thus safeguarding the integrity of underlying surfaces and structures. Furthermore, the incorporation of resin as a binding agent among the fiberglass strands offers an additional safeguard against moisture, augmenting its ability to withstand water and humidity. Consequently, fiberglass mat tissue emerges as a dependable option for moisture resistance, rendering it ideal for a wide range of applications where the prevention of water damage is of utmost importance.

- Q: What are the recommended storage and handling practices for fiberglass mat tissue?

- To ensure the integrity and longevity of fiberglass mat tissue, it is necessary to adhere to a few recommended practices. 1. Storage: Fiberglass mat tissue should be stored in a clean, dry environment to prevent damage from moisture or dirt. Ideally, it should be kept indoors, away from direct sunlight and extreme temperatures. 2. Handling: Proper handling is crucial to avoid damaging the delicate material. It is advisable to wear protective gloves and safety glasses to prevent injuries. Care should be taken to handle it gently, avoiding any tears or creases that may compromise its performance. 3. Transportation: During transportation, it is essential to pack fiberglass mat tissue securely to minimize the risk of damage. Adequate protection should be provided to prevent impact or vibration. If possible, it is preferable to transport it in a dedicated vehicle or container for added safety. 4. Avoid chemical contact: Fiberglass mat tissue should not come into contact with chemicals such as acids, alkalis, or solvents. These substances can degrade and weaken the material. Clean hands should be used when handling, and contact with harmful substances should be avoided. 5. Follow manufacturer's guidelines: It is advisable to adhere to the specific recommendations provided by the manufacturer regarding storage and handling. Different manufacturers may have slightly different requirements, and following them ensures optimal performance and longevity. By adhering to these recommended practices for storage and handling, the integrity of fiberglass mat tissue can be maintained, guaranteeing its readiness for its intended use.

- Q: Can fiberglass mat tissue be used for making lightweight flooring?

- Making lightweight flooring is possible with the use of fiberglass mat tissue. This material is commonly found in the construction and manufacturing industries due to its strength, durability, and lightweight properties. It is created by bonding fine fiberglass strands together with a binder, resulting in a thin, flexible, and lightweight material. Using fiberglass mat tissue for flooring applications offers various advantages. Firstly, its lightweight nature makes it easy to handle and install, reducing the overall weight of the flooring system. This is particularly beneficial in situations where weight is a concern, such as in aircraft or mobile homes. Additionally, fiberglass mat tissue has an excellent strength-to-weight ratio, making it perfect for creating lightweight yet strong flooring. It reinforces and improves the structural integrity of the flooring, making it more resistant to cracking, warping, and other types of damage. Moreover, fiberglass mat tissue is resistant to moisture, chemicals, and fire, making it suitable for areas where these factors are present, such as bathrooms, kitchens, or industrial settings. It also provides good insulation properties, which helps maintain a comfortable indoor environment and reduces energy consumption. In conclusion, fiberglass mat tissue is an excellent choice for creating lightweight flooring due to its strength, durability, moisture resistance, and insulation properties. However, it is important to consider additional factors, such as the specific requirements of the flooring application, load-bearing capacity, and necessary certifications or standards before finalizing the use of fiberglass mat tissue in a flooring project.

- Q: How does the width of fiberglass mat tissue affect its installation?

- The installation process of fiberglass mat tissue can be influenced by its width. When contemplating the width of fiberglass mat tissue, it is vital to consider the specific demands of the application or project. A broader fiberglass mat tissue can offer numerous benefits during installation. Firstly, it enables a greater coverage area, reducing the number of required overlaps and potentially saving time during installation. This can be especially advantageous in large-scale projects where efficiency is of utmost importance. Moreover, a wider width can provide better overall coverage and minimize the risk of potential gaps or weak points in the installation. This can result in a more consistent and reliable end product, ensuring improved performance and durability. However, it is important to note that a wider fiberglass mat tissue may also present certain challenges during installation. It can be more challenging to handle and maneuver, particularly when working in tight or confined spaces. This may necessitate additional caution and attention to ensure proper alignment and smooth application. Additionally, the width of fiberglass mat tissue can impact the amount of resin or adhesive required for installation. A wider width may necessitate a larger quantity of resin or adhesive, potentially leading to an increase in the overall project cost. Ultimately, the choice of fiberglass mat tissue width should be based on the specific requirements and limitations of the project. Factors such as the size of the installation area, the extent of coverage needed, and the available resources should all be taken into account to determine the most suitable width for the application.

- Q: Is fiberglass mat tissue resistant to chemicals?

- Generally, fiberglass mat tissue is resistant to chemicals. Its composition, comprising fine glass fibers bonded together with a resin, grants it exceptional chemical resistance properties. This resistance enables the fiberglass mat tissue to endure exposure to various chemicals without deteriorating or compromising its structural integrity. Nevertheless, it is crucial to acknowledge that the precise chemical resistance of fiberglass mat tissue may differ based on the type and concentration of the chemical it encounters. Therefore, it is advisable to consult the manufacturer's guidelines or perform suitable testing to ensure compatibility with particular chemicals.

Send your message to us

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1700gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords