Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1270mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

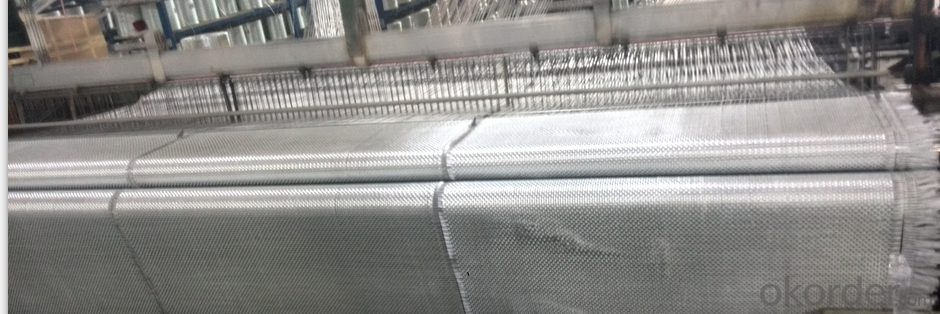

Woven roving Images

Woven roving Specification: weight& thickness

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How does the fiber distribution of fiberglass mat tissue affect its strength?

- The fiber distribution of fiberglass mat tissue plays a crucial role in determining its strength. A more uniform and evenly distributed fiber arrangement enhances the overall strength and structural integrity of the material. This is because the fibers can effectively distribute and share the applied load, preventing localized stress concentrations and potential weak points. In contrast, an uneven or random fiber distribution may lead to areas with fewer or misaligned fibers, reducing the material's overall strength and making it more prone to failure. Therefore, a well-controlled and uniform fiber distribution is essential for maximizing the strength and performance of fiberglass mat tissue.

- Q: What are the potential limitations of using fiberglass mat tissue?

- Some potential limitations of using fiberglass mat tissue include the risk of skin irritation or allergic reactions when handling the material, as well as the need for proper safety precautions to prevent inhalation of fibers. Additionally, fiberglass mat tissue may not be suitable for applications requiring high strength or resistance to extreme temperatures.

- Q: Is fiberglass mat tissue resistant to fading?

- Yes, fiberglass mat tissue is resistant to fading.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. Fiberglass mat tissue is a versatile material that is commonly used in repairing and reinforcing fiberglass structures, including boats. It is designed to provide strength and durability, making it an ideal choice for patching holes, cracks, or damaged areas in fiberglass boat hulls. The mat tissue is typically layered with resin to form a solid and stable repair, ensuring that the boat remains structurally sound. Additionally, fiberglass mat tissue is easy to work with and can be cut to the desired size and shape, making it suitable for various repair applications on fiberglass boats.

- Q: What are the applications of fiberglass mat tissue?

- Fiberglass mat tissue, a versatile material, is utilized in a multitude of industries. Some notable applications include: 1. Construction and Building Materials: Within the construction industry, fiberglass mat tissue serves as a reinforcement material. It is commonly employed in the production of roofing shingles, insulation materials, and wall coverings. The robust and durable nature of fiberglass mat tissue enhances the structural integrity of buildings and bolsters their resistance to external elements such as wind, moisture, and temperature fluctuations. 2. Automotive Industry: The automotive sector extensively utilizes fiberglass mat tissue for manufacturing components like door panels, headliners, trunk liners, and interior trim parts. Due to its lightweight and high strength properties, fiberglass mat tissue is an ideal material for reducing the overall weight of vehicles while maintaining their structural integrity. 3. Marine Industry: The marine industry relies heavily on fiberglass mat tissue for constructing boat hulls, decks, and other structural components. The corrosion-resistant characteristics of fiberglass mat tissue make it well-suited for marine applications where exposure to water and harsh weather conditions is common. 4. Pipe Manufacturing: Fiberglass mat tissue is employed in the production of fiberglass reinforced pipes. These pipes find applications in various industries, including oil and gas, chemicals, and water management. The high strength and corrosion-resistant properties of fiberglass mat tissue make it an excellent choice for manufacturing pipes capable of withstanding high pressure and harsh chemical environments. 5. Filtration Systems: Fiberglass mat tissue plays a vital role in the production of air filters and liquid filtration systems. The fibrous structure of the material enables efficient filtration by trapping dust particles, dirt, and other contaminants. This makes fiberglass mat tissue the preferred choice for applications requiring high-efficiency filtration, such as HVAC systems, industrial air filters, and water treatment plants. In conclusion, fiberglass mat tissue finds extensive and diverse applications in industries ranging from construction and automotive to marine and filtration systems. Its unique properties make it an invaluable material for enhancing structural integrity, reducing weight, and improving performance across various sectors.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: Can fiberglass mat tissue be used for roofing applications?

- Certainly, roofing applications can utilize fiberglass mat tissue. This lightweight and flexible material finds widespread use in the construction industry for a multitude of purposes, with roofing being one of them. It serves as a reinforcement layer, bolstering the strength and durability of roofing systems. Typically, the fiberglass mat tissue is saturated with bitumen or other waterproofing substances to establish a water-resistant shield atop the roof. Additionally, it contributes to augmenting the fire resistance and thermal insulation characteristics of the roof. Furthermore, fiberglass mat tissue's resistance to mold, mildew, and other prevalent roofing problems makes it an excellent option for roofing applications.

- Q: Is fiberglass mat tissue resistant to acids?

- Fiberglass mat tissue is generally resistant to acids, thanks to its excellent corrosion resistance properties. This resistance extends to various acids. When combined with resin, fiberglass mat becomes a strong and durable material that can withstand exposure to a wide range of chemicals, including acids. However, it's important to note that the resistance of fiberglass mat tissue can still be affected by the specific type and concentration of acid. Highly concentrated or aggressive acids, in some cases, may cause damage or degradation to the material over time. Consequently, it is always advisable to consider the specific acid being used and consult the manufacturer's recommendations for compatibility before exposing fiberglass mat tissue to an acidic environment.

- Q: What are the different color options available for fiberglass mat tissue?

- The different color options available for fiberglass mat tissue typically include white, gray, and beige.

- Q: Can fiberglass mat tissue be used in marine applications?

- Certainly! Fiberglass mat tissue finds its utility in the realm of marine applications. It is a lightweight and flexible substance that is extensively employed in the construction and repair of boats. Its commendable strength and durability render it suitable for marine environments that entail exposure to water, salt, and other severe conditions. It is frequently employed as a reinforcement layer in the fabrication of boat hulls, decks, and other structural constituents. Its incorporation augments the strength and rigidity of composite materials employed in marine applications, thus bolstering their overall performance and lifespan. Furthermore, fiberglass mat tissue exhibits resistance to corrosion and possesses favorable water resistance properties, rendering it an apt choice for marine applications.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1270mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords