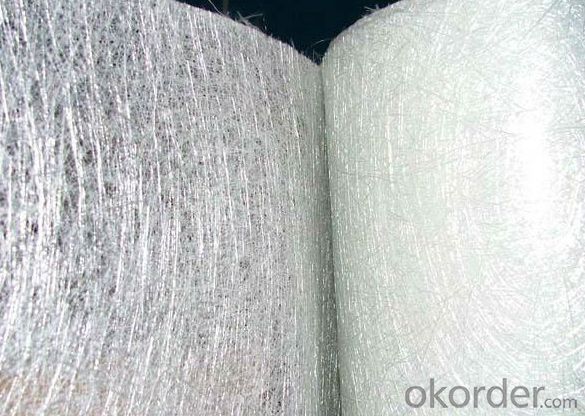

Fiberglass Mat Tissue - e-glass Chopped Strand Mat 2900mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 2900mm

2.Main Features

With Excellent compatibility with resin,heating resistance,Faster and well wet-out

Chopped strand mats are made of chopped strands of 50mm in length,which are randomly dispersed and bonded together by the polyester binder in powder or emulsion.

Chopped strand mats are mainly used in FRP fields,such as hand lay-up,filament winding and molding process. The typical products are panels,tanks,boats,automotive parts,cooling towers,pipes and so on.

3.Specification

AreaWeight :300GSM

Roll Weiht: 145KG

Roll Width: 2900mm

Binder: Emulsion

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue is a type of reinforcement material that is commonly used in the production of composite pipes. It provides strength and durability to the pipes, making them suitable for various applications. The fiberglass mat tissue is typically impregnated with a resin, such as polyester or epoxy, which helps to bind the fibers together and create a solid structure. This reinforcement material is known for its lightweight properties and excellent corrosion resistance, making it an ideal choice for composite pipe manufacturing. Additionally, fiberglass mat tissue can be easily molded into different shapes and sizes, allowing for the production of pipes with varying diameters and lengths. Overall, the use of fiberglass mat tissue in composite pipe manufacturing offers numerous advantages, including enhanced strength, durability, and resistance to harsh environmental conditions.

- Q: Can fiberglass mat tissue be used for architectural applications?

- Yes, fiberglass mat tissue can be used for architectural applications. Fiberglass mat tissue is a versatile material that offers several benefits when used in architectural projects. It is commonly used as a reinforcement material in the construction of various architectural elements such as roofings, facades, and walls. One of the main advantages of fiberglass mat tissue for architectural applications is its high strength-to-weight ratio. It provides excellent structural integrity while being lightweight, making it ideal for use in large-scale architectural projects. Additionally, fiberglass mat tissue is known for its durability and resistance to extreme weather conditions, making it suitable for both interior and exterior applications. Furthermore, fiberglass mat tissue offers excellent fire resistance properties, which is an important factor when considering architectural safety standards. It has a high melting point and does not contribute to the spread of flames, making it a reliable choice for fire-resistant applications. In terms of aesthetics, fiberglass mat tissue can be easily molded into various shapes and designs, allowing architects to explore creative possibilities. It can be painted or coated to achieve the desired visual appearance, making it a versatile material for architectural finishes. Overall, fiberglass mat tissue is a reliable and versatile material that can be effectively used for architectural applications. Its strength, durability, fire resistance, and aesthetic adaptability make it a suitable choice for a wide range of architectural projects.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Yes, fiberglass mat tissue must meet specific certifications and standards. These can include ASTM International standards such as ASTM D7055 for fiberglass mat used in roofing applications or ASTM C1667 for fiberglass mat used in gypsum panels. Additionally, the product may need to comply with industry-specific certifications like ICC-ES for construction materials or UL for fire resistance. Meeting these certifications and standards ensures the quality and performance of fiberglass mat tissue in various applications.

- Q: Can fiberglass mat tissue be used for roofing?

- Yes, fiberglass mat tissue can be used for roofing. Fiberglass mat tissue is a type of material that is commonly used in the construction industry for various purposes, including roofing. It is known for its durability, strength, and ability to withstand harsh weather conditions. Fiberglass mat tissue is often used as a reinforcement layer in roofing systems, providing additional strength and stability to the roof. It helps to improve the overall performance and longevity of the roof by offering excellent resistance to water, fire, and other external factors. Additionally, fiberglass mat tissue is lightweight and flexible, making it easier to handle and install on roofs of different shapes and sizes. Overall, fiberglass mat tissue is a suitable choice for roofing applications due to its superior properties and performance.

- Q: Is fiberglass mat tissue compatible with vacuum infusion processes?

- Yes, fiberglass mat tissue is compatible with vacuum infusion processes. It is commonly used in vacuum infusion techniques as it allows for the distribution of resin evenly throughout the laminate, resulting in a strong and uniform composite part.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Yes, fiberglass mat tissue is suitable for soundproofing. It is an effective material for absorbing and dampening sound waves, making it a popular choice for soundproofing applications in buildings, vehicles, and other structures.

- Q: Can fiberglass mat tissue be used for making insulation panels?

- Indeed, insulation panels can be manufactured using fiberglass mat tissue. This lightweight and flexible material possesses remarkable thermal insulation characteristics. Typically, it is utilized as a reinforcing layer during the production process of insulation panels. By doing so, the mat tissue not only fortifies the panels, but also ensures efficient insulation against heat transfer. Moreover, fiberglass mat tissue exhibits resistance against moisture, mold, and mildew, rendering it highly suitable for insulation purposes.

- Q: How is fiberglass mat tissue bonded to surfaces?

- Adhesive materials are commonly utilized to bond fiberglass mat tissue to surfaces. To initiate the bonding process, the adhesive is applied onto the surface where the fiberglass mat tissue will be attached. Typically, a two-part epoxy resin or a specialized fiberglass adhesive, specifically formulated for bonding fiberglass materials, is used. Following the manufacturer's instructions, the adhesive is thoroughly mixed and then evenly spread onto the surface using a brush, roller, or trowel. With utmost care, the fiberglass mat tissue is then placed onto the adhesive-covered surface and firmly pressed down to ensure optimal adhesion. Subsequently, the adhesive is left to cure for the recommended duration, allowing it to solidify and establish a robust bond between the fiberglass mat tissue and the surface. This bonding technique guarantees the secure attachment of the fiberglass mat tissue to the surface, offering reinforcement, protection, or other desired attributes based on the specific application.

- Q: Can fiberglass mat tissue be recycled?

- Indeed, recycling is a viable option for fiberglass mat tissue. Fiberglass, composed of glass fibers and resin, allows for reusing both elements. To recycle, the glass fibers and resin are separated, typically via mechanical grinding or melting techniques. The isolated fibers are subsequently employed in the production of fresh fiberglass products like insulation, roofing materials, or even new fiberglass mat tissue. The recycling of fiberglass plays a critical role in lessening the environmental impact of this material by diverting it from landfills and conserving valuable resources. It's important to acknowledge, however, that the recycling process can be intricate and costly, which means not all recycling facilities may accept fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation in power generation facilities?

- Yes, fiberglass mat tissue can be used for insulation in power generation facilities. Fiberglass mat tissue is a versatile material that is commonly used for insulation purposes due to its excellent thermal and electrical insulation properties. It is resistant to high temperatures and can effectively trap and prevent the transfer of heat, making it suitable for use in power generation facilities where heat management is crucial. Additionally, fiberglass mat tissue is lightweight, easy to install, and offers high durability and longevity, making it a cost-effective choice for insulation in power generation facilities.

Send your message to us

Fiberglass Mat Tissue - e-glass Chopped Strand Mat 2900mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords