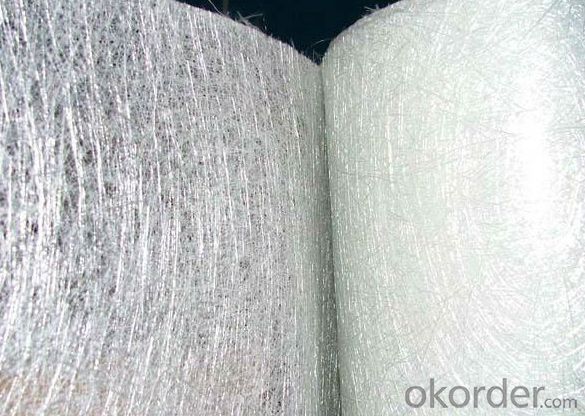

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Our chopped strand mat is with width 2500mm, packing in wooden box (pallet)with width 2550mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

2.Main Features

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 |

3-4

|

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

Package for Big Width Mat:

1, Each roll will be wound on 4 inches paper core, strong enough for the loading and transportation;

2, Each roll of mat will be wrapped by plastic film;

3, 9 Rolls wil be packed in one wooden frame box;

4, Both side closed by polywood;

5, Steel strip is used for fasten the wooden box.

4. FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

1000kgs;

4. Can you provide sample?

Yes, we can offer free sample for you.

5. Payment terms?

Accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

7. What is the Production Lead Time?

1 *40HQ each day, depend on the size of the mat.

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Yes, fiberglass mat tissue is suitable for wind energy applications. Fiberglass mat tissue is a lightweight and durable material that is commonly used in the construction of wind turbine blades. It provides excellent strength and stiffness, making it ideal for withstanding the high stresses and forces that wind turbines are subjected to. Additionally, fiberglass mat tissue is resistant to corrosion and degradation from UV radiation, ensuring the longevity and performance of wind turbine blades. Overall, the use of fiberglass mat tissue in wind energy applications allows for the production of efficient and reliable wind turbines that can generate clean and sustainable energy.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as its quality, usage, and exposure to external conditions. Generally, fiberglass mat tissue is designed to be highly durable and long-lasting. When properly installed and maintained, it can typically last for several decades. However, it is important to note that fiberglass mat tissue can deteriorate over time due to environmental factors such as UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can accelerate the degradation process. To maximize the lifespan of fiberglass mat tissue, it is crucial to follow the manufacturer's guidelines for installation, maintenance, and periodic inspections. Regular inspections can help identify any signs of wear, damage, or degradation early on, allowing for timely repairs or replacements. It is recommended to consult with a professional or the manufacturer for specific information regarding the expected lifespan of a particular fiberglass mat tissue, as it can vary depending on the specific product and its intended application.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass boats?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass boats. It is often used in boat construction and repair to strengthen the hull and improve its durability. The mat tissue is typically applied with resin to create a strong and rigid composite structure.

- Q: Can fiberglass mat tissue be used for mold-making?

- No, fiberglass mat tissue is not typically used for mold-making.

- Q: Can fiberglass mat tissue be used for roofing?

- Yes, fiberglass mat tissue can be used for roofing. It is commonly used as a reinforcement material for roofing systems due to its high strength and durability. It helps to enhance the structural integrity of the roof and improve its resistance to weathering and other external factors.

- Q: Is fiberglass mat tissue suitable for insulation in educational facilities?

- Yes, fiberglass mat tissue is suitable for insulation in educational facilities. Fiberglass mat tissue is commonly used in insulation applications due to its excellent thermal insulation properties. It is a lightweight and cost-effective material that can effectively insulate buildings, including educational facilities, against heat loss or gain. Fiberglass mat tissue is also known for its fire-resistant properties, which is an important aspect to consider in any building, especially in educational facilities where the safety of students and staff is a top priority. Additionally, fiberglass mat tissue is easy to install and does not require extensive maintenance, making it a convenient choice for insulation in educational facilities.

- Q: How does fiberglass mat tissue compare to fiberglass insulation batts?

- Fiberglass mat tissue and fiberglass insulation batts serve different purposes and have distinct characteristics. Fiberglass mat tissue is primarily used as a reinforcement material in various applications such as roofing, wall coverings, and composite materials. It provides strength, durability, and improved dimensional stability to the finished product. On the other hand, fiberglass insulation batts are specifically designed for thermal insulation purposes, typically used in walls, ceilings, and attics to prevent heat transfer. They are engineered to trap air pockets within the material, providing excellent thermal resistance. While both products are made from fiberglass and offer certain insulation properties, their specific applications and performance differ significantly.

- Q: How does fiberglass mat tissue perform in terms of thermal resistance?

- Fiberglass mat tissue performs exceptionally well in terms of thermal resistance. Due to the inherent properties of fiberglass, such as low thermal conductivity and high melting point, the mat tissue effectively acts as a barrier against heat transfer. It efficiently blocks the conduction of heat, limiting thermal energy from passing through the material. This makes fiberglass mat tissue an excellent choice for insulation applications where thermal resistance is crucial, such as in buildings, industrial equipment, and automotive components. Additionally, fiberglass mat tissue is known for its fire-resistant properties, further enhancing its ability to withstand high temperatures and provide excellent thermal insulation.

- Q: Is fiberglass mat tissue resistant to chemicals?

- Yes, fiberglass mat tissue is generally resistant to chemicals. The composition of fiberglass mat tissue, which consists of fine glass fibers bonded together with a resin, provides it with excellent chemical resistance properties. This resistance allows the fiberglass mat tissue to withstand exposure to a wide range of chemicals without deteriorating or losing its structural integrity. However, it is important to note that the specific chemical resistance of fiberglass mat tissue may vary depending on the type and concentration of the chemical it comes into contact with. Therefore, it is always advisable to consult the manufacturer's guidelines or conduct appropriate testing to ensure compatibility with specific chemicals.

- Q: Can fiberglass mat tissue be used for insulating metal buildings?

- Yes, fiberglass mat tissue can be used for insulating metal buildings. It is a commonly used insulation material due to its excellent thermal properties and ability to resist heat transfer.

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords