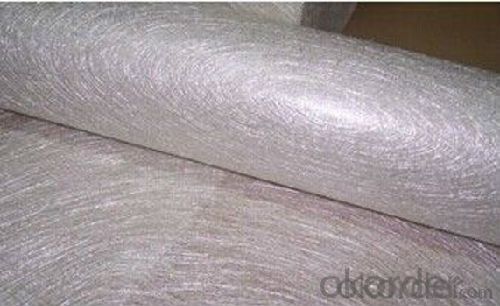

Fiberglass Mat Tissue C-Glass Chopped Strand Mat-Powder, Width 1250mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Chopped strand mat is a non-woven reinforced material. It is manufactured by spreading continuous filament roving of 50mm in length, distributed it at random uniformly held together with powder or emulsion binder.

Packaging & Delivery of C-glass Chopped Strand Mat

Packaging Detail: | cartons and pallets |

Delivery Detail: | within two weeks |

Traits of C-glass Chopped Strand Mat

C-glass fiber chopped strand mat:

1. good wet-out

2. evenly distribution of fiber and binder

3. high mechanical strength etc.

Specification C-glass Chopped Strand Mat

We could provide E-Glass Powder Chopped Strand Mat and E-Glass Emulsion Chopped Strand Mat.

Specs | Roll length(m) | Width(mm) | Roll weight(kg) | Compatible Resin |

EMC225 | 1040mm | 144 | 30 | UP VE |

EMC300 | 1040mm | 96 | 30 | UP VE |

EMC380 | 1040mm | 80 | 30 | UP VE |

EMC450 | 2080mm | 64 | 60 | UP VE |

EMC600 | 2080mm | 48 | 60 | UP VE |

EMC900 | 2080mm | 32 | 60 | UP VE |

The products is raw material to produce FRP products.

Binder type: Emulsion or Power

Packing: by carton or by pallet, or as your requested

FAQ

1. How long will you get reply?

Any inquiry will be replied within 24 hours. Usually we will reply within 12 hours.

2. How long is warranty period?

We provide 3 year warranty period.

3. What is your MOQ?

Our MOQ is 10000 kgs.

- Q: What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is quite high due to its inherent properties and construction. Fiberglass mat tissue is composed of fine glass fibers that are randomly arranged and bonded together with a binder material. This arrangement creates a strong and flexible mat that can withstand impacts and external forces. The random orientation of the glass fibers allows for the distribution of stress and energy across the entire mat tissue. When an impact is applied, the fibers absorb and disperse the force, preventing it from being concentrated in one area. This property helps to minimize the risk of cracks, fractures, or failures in the material. Additionally, the binder material used in fiberglass mat tissue provides further reinforcement and cohesion to the structure. It acts as a bonding agent, keeping the glass fibers in place and enhancing their overall strength. This bonding ensures that the mat tissue remains intact and resilient even under high impact loads. Due to its excellent impact resistance, fiberglass mat tissue is commonly used in various applications where durability and strength are essential. It is often utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics (FRP), to enhance their impact resistance and structural integrity. It is also frequently employed in the construction industry for applications like roofing, wall insulation, and soundproofing, where it provides protection against impacts and external forces. Overall, the impact resistance of fiberglass mat tissue is a key characteristic that contributes to its widespread use in numerous industries. Its ability to withstand impacts and distribute forces makes it a reliable material for applications that require strength, durability, and protection against external forces.

- Q: How long does fiberglass mat tissue typically last?

- The duration of fiberglass mat tissue's lifespan is subject to fluctuation due to a variety of factors, including material quality, exposure to environmental conditions, and maintenance level. Typically, fiberglass mat tissue has a lifespan of 20 to 30 years. Nevertheless, by implementing appropriate installation techniques and consistent maintenance practices, it has the potential to endure beyond this time frame. It is crucial to emphasize that routine inspections and maintenance aid in the detection of any indications of deterioration or harm, permitting prompt repairs or replacements to guarantee its longevity.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Yes, fiberglass mat tissue may require some special tools for installation. These tools can include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment such as gloves and goggles to protect the installer from potential hazards. Additionally, some installations may require the use of a heat gun or torch to activate or cure the resin. It is important to read and follow the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used to ensure proper installation and to determine if any special tools are required.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Acoustic panels can utilize fiberglass mat tissue for sound absorption. This lightweight material is commonly employed for insulation purposes and is known for its exceptional sound-absorbing properties. By effectively reducing noise levels, it enhances the functionality of acoustic panels. Moreover, fiberglass mat tissue is a preferred choice for DIY projects due to its ease of use. However, it is crucial to consider other factors such as panel design, thickness, density, and installation method to maximize the effectiveness of acoustic panels. Therefore, consulting experts or conducting thorough research is recommended to determine if fiberglass mat tissue is suitable for your specific acoustic panel requirements.

- Q: What are the recommended storage and handling practices for fiberglass mat tissue?

- The recommended storage and handling practices for fiberglass mat tissue include keeping it in a dry and well-ventilated area, away from direct sunlight or heat sources. It should be stored horizontally on a clean and level surface to prevent any damage or deformation. When handling, it is advisable to wear protective gloves and safety glasses to avoid any contact with the skin or eyes. Additionally, it is important to handle the material with care to prevent tearing or puncturing, and to avoid any exposure to moisture or chemicals that may degrade its quality.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- There are several different manufacturing processes for fiberglass mat tissue, each of which is designed to produce a specific type of mat with unique properties. One common manufacturing process is the wet-laid process. In this method, glass fibers are first chopped into small pieces and then dispersed in a water-based slurry. The slurry is then spread onto a moving screen or belt, allowing the water to drain away and leaving behind a mat of randomly oriented fibers. The mat is then dried and further processed to achieve the desired thickness and density. Another manufacturing process is the dry-laid process. In this method, glass fibers are first formed into a loose, fluffy mat using air or mechanical means. The loose fibers are then bonded together using a binder material, such as a resin or latex, which is sprayed onto the fibers. The binder cures, creating a cohesive mat with controlled thickness and density. A third manufacturing process is the stitch-bonded process. This method involves mechanically stitching individual glass fibers together using a series of needles. The needles pierce the fibers and interlock them, creating a bonded fabric. This process allows for the production of mats with high strength and dimensional stability. Finally, there is the spunbond process. This process involves extruding molten glass through fine spinnerets to form continuous filaments. The filaments are then collected onto a moving belt or screen, where they are bonded together using heat or a binder. This process produces mats with uniform fiber distribution and high strength. Overall, the choice of manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, such as strength, thickness, density, and dimensional stability. Each process has its own advantages and disadvantages, and manufacturers will select the most suitable process based on their specific requirements.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. Fiberglass mat tissue is a common material used for thermal and acoustic insulation due to its excellent insulation properties. It is highly resistant to heat, moisture, and chemicals, making it suitable for laboratory settings. Additionally, fiberglass mat tissue is lightweight and easy to install, allowing for quick and efficient insulation in research laboratories. Its low thermal conductivity helps to maintain stable temperature conditions, ensuring optimal conditions for experiments and reducing energy consumption. Therefore, fiberglass mat tissue is a viable choice for insulation in research laboratories.

- Q: Does fiberglass mat tissue require any special handling or storage requirements?

- Yes, fiberglass mat tissue does require special handling and storage requirements. It should be stored in a dry, clean, and well-ventilated area to prevent moisture absorption. It should also be kept away from direct sunlight and extreme temperatures to maintain its quality. Additionally, it is important to handle fiberglass mat tissue with care to avoid any damage or injury, as it can be sharp and fragile.

- Q: What is the lifespan of fiberglass mat tissue?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, the conditions it is exposed to, and the level of maintenance it receives. However, fiberglass mat tissue is generally known for its durability and long lifespan. With proper installation and regular maintenance, fiberglass mat tissue can last for many decades. It is resistant to corrosion, moisture, and UV radiation, which helps to prolong its lifespan. Additionally, fiberglass mat tissue is often used in applications such as roofing, insulation, and reinforcement, where it is designed to withstand harsh conditions and provide long-term performance.

- Q: Can fiberglass mat tissue be used for reinforcing concrete structures?

- Indeed, fiberglass mat tissue can be utilized to fortify concrete structures. This material, crafted from woven glass fibers, is thin and lightweight. It boasts a commendable strength-to-weight ratio and exceptional resistance to corrosion, rendering it an optimal selection for reinforcing concrete structures. When employed as reinforcement in concrete, fiberglass mat tissue is typically embedded within the concrete mixture. This inclusion aids in enhancing the concrete's tensile strength and ductility, effectively preventing cracks and augmenting its overall durability. Fiberglass mat tissue is frequently employed in various applications, including precast concrete panels, concrete pipes, and concrete overlays. These structures benefit from the reinforcement provided by fiberglass mat tissue, enabling them to endure heavy loads and resist cracking, particularly in areas where concrete alone may prove inadequate. Additionally, fiberglass mat tissue exhibits resistance to chemicals and environmental elements, qualifying it for use in harsh conditions or exposed surroundings. It does not succumb to corrosion or rust like traditional steel reinforcements, ensuring the longevity and structural integrity of the concrete structure. In conclusion, fiberglass mat tissue stands as a dependable and efficient choice for reinforcing concrete structures. Its lightweight nature, impressive strength, corrosion resistance, and durability have solidified its status as a popular option within the construction industry.

Send your message to us

Fiberglass Mat Tissue C-Glass Chopped Strand Mat-Powder, Width 1250mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords