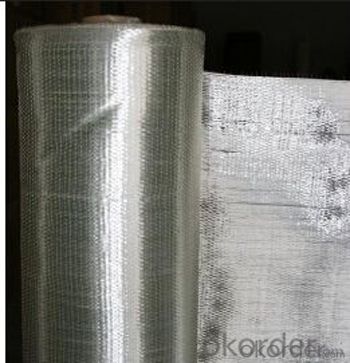

Fiberglass Mat Tissue - C-Glass Stitch Chopped Strand Mat 380gsm, 50-2400mm Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass C-glass Stitch Chopped Strand Mat with Density

Product Description

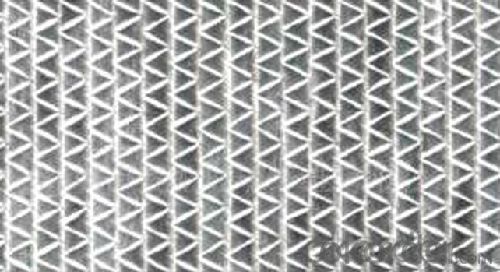

Fiberglass stitch chopped strand mat is the mat made of fiberglass roving which is at first be cut into certain length and evenly unfolded in all directions and then stitched with polyester yarn.

Product Treatures

• Fiberglass no certain direction, good homogeneity.

• No powder or emulsion; sink quickly and easy to operate

• High tensile strength, easy to operate

• Good impact strength of finished products

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, RTM, molded, hand lay up, etc.

• Ultimate products: Liner layer of tube, pultruded profiles, FRP body of boat, insulation board

Image:

Specifications

Specifications | Fibre type | Areal weight | Width |

(g/㎡) | (mm) | ||

EMK 300 | E-Glass | 300 | 50-2400 |

EMK380 | E-Glass | 380 | 50-2400 |

EMK450 | E-Glass | 450 | 50-2400 |

CMK 300 | C-Glass | 300 | 50-2400 |

CMK380 | C-Glass | 380 | 50-2400 |

CMK450 | C-Glass | 450 | 50-2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||

FAQ

1. Payment terms?

We can accept L/C, T/T etc.

2. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

3. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

- Q: Is fiberglass mat tissue chemically resistant?

- Indeed, fiberglass mat tissue possesses chemical resistance. Crafted from finely dispersed glass fibers that are haphazardly arranged and held together with a resin binder, this composition endows the material with superb resistance to an extensive array of chemicals, encompassing acids, alkalis, solvents, and oils. It frequently finds utility in sectors like chemical processing, petrochemicals, and wastewater treatment, where encounters with diverse chemicals are prevalent. The chemical resilience of fiberglass mat tissue renders it a fitting selection for applications that necessitate protection against corrosion and long-lasting sturdiness.

- Q: Is fiberglass mat tissue resistant to alkalis?

- Yes, fiberglass mat tissue is resistant to alkalis.

- Q: Can fiberglass mat tissue be used for waterproofing?

- Yes, fiberglass mat tissue can be used for waterproofing. It is commonly used as a reinforcement material in waterproofing systems, such as for roofs, walls, and foundations. The fiberglass mat tissue is impervious to water and helps to provide an additional layer of protection against moisture intrusion.

- Q: Is fiberglass mat tissue suitable for railway infrastructure?

- Yes, fiberglass mat tissue is suitable for railway infrastructure. Fiberglass mat tissue is a strong and durable material that offers excellent resistance to corrosion, weathering, and chemical degradation. It is commonly used in the construction industry for reinforcing structures such as bridges, tunnels, and platforms. In the case of railway infrastructure, fiberglass mat tissue can provide several benefits. Firstly, it has high tensile strength, which means it can withstand the heavy loads and vibrations associated with train traffic. This helps to prevent cracking and structural damage, ensuring the longevity and safety of the railway system. Additionally, fiberglass mat tissue is non-conductive, which is a crucial characteristic for railway infrastructure. It helps to prevent the risk of electrical shocks and short circuits, which are common concerns in rail networks. This makes fiberglass mat tissue a reliable choice for railway infrastructure, especially in areas where electrical lines are present. Furthermore, fiberglass mat tissue is lightweight and easy to handle, making it convenient for installation in railway projects. It is also resistant to fire, making it a safe choice for railway infrastructure in terms of fire protection. Overall, fiberglass mat tissue is a suitable material for railway infrastructure due to its strength, durability, non-conductive nature, and fire resistance. Its use in railway construction can contribute to the reliability, longevity, and safety of the railway system.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. Fiberglass mat tissue is a versatile material that is commonly used for reinforcing and repairing fiberglass structures, including shower stalls. It is designed to provide strength and durability to the repaired area, ensuring a long-lasting and reliable fix. When used in combination with a suitable fiberglass resin, fiberglass mat tissue can effectively repair cracks, holes, and other damages in fiberglass shower stalls. However, it is important to carefully follow the manufacturer's instructions and guidelines for proper application and curing to ensure the best results.

- Q: Can fiberglass mat tissue be used for insulating windows?

- Certainly! Insulating windows is possible with the utilization of fiberglass mat tissue. This lightweight and adaptable material is frequently employed for insulation objectives. With its commendable thermal resistance, it effectively diminishes the escape or entry of heat through windows. By simply affixing a layer of fiberglass mat tissue onto the window surface, it greatly enhances the window's insulation capabilities, thereby reducing drafts and heat transfer. Moreover, this multifunctional fiberglass mat tissue also effectively minimizes noise transmission, rendering it a versatile choice for both thermal and acoustic insulation purposes.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. Fiberglass mat tissue is a lightweight material that is commonly used for sound absorption and insulation purposes. It has excellent sound-absorbing properties and can effectively reduce noise levels in various applications, including acoustic panels. It is often used as the core material in acoustic panels to enhance their sound-absorbing capabilities. Additionally, fiberglass mat tissue is easy to work with, making it a popular choice for DIY acoustic panel projects. However, it is important to note that the effectiveness of acoustic panels also depends on other factors such as panel design, thickness, density, and installation method. Therefore, it is recommended to consult with experts or conduct thorough research to ensure that fiberglass mat tissue is the appropriate material for your specific acoustic panel needs.

- Q: Is fiberglass mat tissue suitable for oil and gas applications?

- Yes, fiberglass mat tissue is suitable for oil and gas applications. Fiberglass mat tissue is a lightweight, strong, and durable material that can withstand the harsh conditions commonly found in the oil and gas industry. It has excellent resistance to chemicals, including oil and gas, making it an ideal choice for applications such as pipeline insulation, tank lining, and filtration systems. Additionally, fiberglass mat tissue has low moisture absorption, good thermal insulation properties, and can be easily fabricated into different shapes and forms, making it a versatile material for various oil and gas applications.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. It is commonly used in boat manufacturing due to its strength, durability, and ability to provide structural reinforcement.

- Q: What are the key properties of fiberglass mat tissue?

- The key properties of fiberglass mat tissue include high strength and durability, excellent fire resistance, good thermal insulation properties, and resistance to chemicals and moisture. Additionally, it is lightweight, easy to handle and install, and offers good dimensional stability.

Send your message to us

Fiberglass Mat Tissue - C-Glass Stitch Chopped Strand Mat 380gsm, 50-2400mm Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords