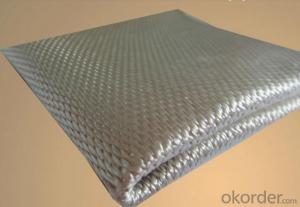

Vermiculite Coated Fiberglass Fabric for River Bank - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

No long-term creep : as a reinforcing material , with the ability to resist deformation under the load in the long-term creep resistance is extremely important, the glass fiber will not creep , to ensure that the products can long-term performance .

3.Application

ysical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

4.FAQ

good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

- Q: What are the different thickness options for fiberglass fabric?

- Fiberglass fabric is available in various thickness options to cater to different needs and applications. The thickness of fiberglass fabric is usually measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). Common thickness options for fiberglass fabric range from lightweight to heavy-duty. Lightweight fiberglass fabrics typically have a thickness of around 0.5 oz/yd² (17 g/m²) to 1.5 oz/yd² (51 g/m²). These fabrics are commonly used in applications where weight is a concern, such as in the aerospace industry or for lightweight repair work. Medium-weight fiberglass fabrics have a thickness ranging from around 2 oz/yd² (68 g/m²) to 4 oz/yd² (136 g/m²). These fabrics offer a good balance between strength and flexibility, making them suitable for a wide range of applications. They are commonly used in boat building, automotive repairs, and general reinforcement tasks. Heavy-duty fiberglass fabrics are thicker and more robust, typically ranging from 6 oz/yd² (204 g/m²) to 10 oz/yd² (340 g/m²) or more. These fabrics provide excellent strength and durability, making them suitable for demanding applications such as industrial insulation, heavy machinery reinforcement, or in the construction industry. It is important to note that the thickness of fiberglass fabric can affect its handling characteristics, as well as its overall strength and flexibility. Therefore, it is crucial to select the appropriate thickness option based on the specific requirements of the project or application at hand.

- Q: Are fiberglass fabrics suitable for use in the agricultural industry?

- Yes, fiberglass fabrics are suitable for use in the agricultural industry. Fiberglass fabrics offer several properties that make them ideal for agricultural applications. Firstly, fiberglass is known for its high strength and durability, making it capable of withstanding the harsh conditions often found in agricultural settings. This means that fiberglass fabrics can be used for various purposes such as covering greenhouses, protecting crops from pests and extreme weather conditions, and reinforcing agricultural equipment. Additionally, fiberglass fabrics are resistant to chemicals and UV radiation, which is essential in the agricultural industry as it often involves the use of fertilizers, pesticides, and exposure to sunlight. The resistance to chemicals ensures that the fiberglass fabrics will not degrade or be negatively affected by these substances. Furthermore, the UV resistance prevents the fabric from deteriorating or becoming brittle when exposed to sunlight for extended periods. Another advantage of fiberglass fabrics in the agricultural industry is their fire resistance. This property is crucial as it helps to prevent the spread of fire in case of accidents or incidents involving flammable materials commonly found in agricultural settings. Moreover, fiberglass fabrics are lightweight and easy to handle, making them convenient for various applications in the agricultural industry. They can be easily cut and tailored to fit specific requirements, allowing for customization based on the needs of farmers and agricultural workers. Overall, the strength, durability, chemical resistance, UV resistance, fire resistance, and ease of handling make fiberglass fabrics highly suitable for use in the agricultural industry. They provide a reliable and versatile solution for various applications, contributing to the efficiency and productivity of agricultural operations.

- Q: What are the safety precautions when working with fiberglass fabric?

- To protect yourself from potential hazards when working with fiberglass fabric, it is crucial to adhere to certain safety measures. Here are some essential precautions to keep in mind: 1. Personal Protective Equipment (PPE): It is imperative to wear the appropriate PPE, such as goggles or safety glasses, a respirator or mask, gloves, and protective clothing. These items will help reduce the likelihood of inhaling fiberglass particles, getting them in your eyes, or having direct skin contact. 2. Ventilation: Ensuring that the work area has proper ventilation is essential to prevent the buildup of fiberglass dust or fumes. If working indoors, utilize exhaust fans or open windows to facilitate airflow and eliminate any airborne particles. 3. Dust Control: To minimize the generation of fiberglass dust, employ wet methods, such as wetting the fabric before cutting or using a water mist to control airborne particles. Additionally, consider using a dust collection system or vacuum with a HEPA filter to capture any produced fiberglass dust. 4. Cutting and Handling: When cutting fiberglass fabric, utilize suitable tools like shears or a rotary cutter to avoid fraying. Handle the fabric with care to prevent the release of loose fibers into the air. Whenever possible, use pre-cut fiberglass pieces to reduce the need for on-site cutting. 5. Cleanup: Once the work is completed, clean up any fiberglass dust or debris using a vacuum cleaner equipped with a HEPA filter. Avoid using compressed air or brooms as they can disperse particles into the air. Dispose of any waste material in accordance with local regulations. 6. Hygiene: Maintain good personal hygiene by thoroughly washing your hands and face after working with fiberglass fabric. Launder any contaminated clothing separately to prevent cross-contamination. 7. Training: It is crucial to ensure that all individuals working with fiberglass fabric receive proper training on potential hazards, safety procedures, and the correct usage of PPE. Regularly review and update safety protocols to foster a safe working environment. By adhering to these safety precautions, you can minimize the risks associated with working with fiberglass fabric and safeguard your health and well-being.

- Q: How is fiberglass fabric printed?

- Fiberglass fabric is typically printed using a process called screen printing. In this method, a mesh screen is used to transfer ink onto the fabric, creating the desired design or pattern. The screen is prepared by blocking out areas that are not to be printed, and then ink is pushed through the screen onto the fabric using a squeegee. This allows for precise and durable printing on fiberglass fabric.

- Q: What kind of fiberglass fabric and asphalt paint do you use for 5mm thick fiberglass?

- Resin and glass cloth composite called resin glass fiber reinforced plastics, commonly known as glass fiber reinforced plastic

- Q: Can fiberglass fabric be used for making molds?

- Yes, fiberglass fabric can be used for making molds. Fiberglass is a versatile material that is commonly used in the construction and manufacturing industries. It is known for its strength, durability, and ability to be molded into various shapes. When used for making molds, fiberglass fabric is typically layered with a resin or epoxy to create a rigid and durable structure. This combination allows for easy release of the molded object and provides a smooth finish. Fiberglass fabric can be used for a variety of mold-making applications, such as for creating prototypes, sculptures, or even industrial molds.

- Q: What's the best form of roof waterproof?

- The roof of the house, because of the need to withstand long-term weather erosion, so the waterproof requirements are higher, so that the need of rigid waterproof waterproof and flexible combination construction, namely the first brush K11 flexible waterproof slurry, and then do a protective layer of mortar waterproof agent, which can meet the demand of the waterproof.At the same time, roof waterproof, the ground is required to do all, the wall generally back high 30 centimeters or so on it.

- Q: What are the different roll lengths available for fiberglass fabric?

- There are various roll lengths available for fiberglass fabric, depending on the manufacturer and the specific application. Common roll lengths for fiberglass fabric range from 50 yards to 100 yards. However, it is important to note that some manufacturers may offer custom roll lengths to cater to specific project needs. These custom lengths can vary significantly, ranging from shorter rolls suitable for small-scale projects to longer rolls suitable for larger industrial applications. It is recommended to check with the manufacturer or supplier to determine the available roll lengths for fiberglass fabric that best suit your specific requirements.

- Q: What are the differences in the quality and performance of domestic glass fiber cloth and imported fiberglass fabric?

- Glass fiber is made up of glass fiber yarn, stacked into a network structure to intercept and absorb impurities, can break the oil in the water as a knife, collect water, improve the quality of oil, and extend the life of equipment.

- Q: What about the leaking water made of fiberglass cloth?

- The water leakage in the water tank made of glass fiber cloth can be applied by asphalt. After the asphalt is solidified, water leakage can be prevented.

Send your message to us

Vermiculite Coated Fiberglass Fabric for River Bank - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords