Silicone Coated Fiberglass Scrim Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric Coated with Silicone Rubber

Fiberglass Fabric Description

Silicone coated fiberglass fabricare made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

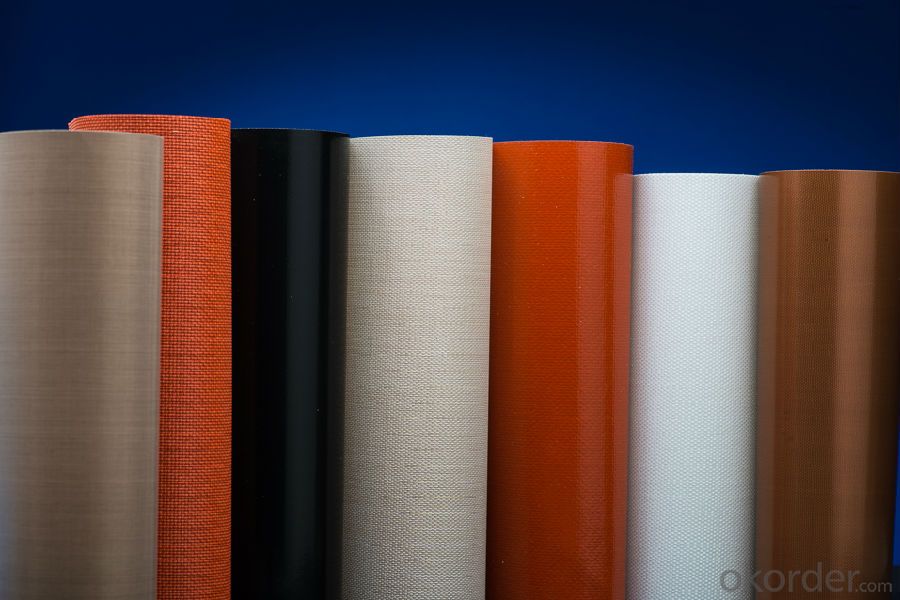

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: What are the different fiberglass fabric finishes for abrasion resistance?

- There are several different fiberglass fabric finishes that are specifically designed to enhance abrasion resistance. These finishes are applied to the fabric during the manufacturing process and serve to improve the fabric's durability and resistance to wear and tear. One commonly used fiberglass fabric finish for abrasion resistance is a silicone coating. This coating forms a protective layer on the fabric's surface, making it more resistant to abrasion and ensuring a longer lifespan. Silicone-coated fiberglass fabrics are often used in applications where high levels of abrasion are expected, such as conveyor belts and industrial curtains. Another popular finish for abrasion resistance is a PVC coating. This type of coating provides a strong barrier against friction and wear, making the fabric more resistant to tears, punctures, and other forms of damage. PVC-coated fiberglass fabrics are commonly used in applications such as protective clothing, tents, and covers for machinery and equipment. In addition to silicone and PVC coatings, there are also other finishes available for enhancing abrasion resistance in fiberglass fabrics. For example, some fabrics may be treated with a polyurethane coating, which provides similar benefits to silicone and PVC coatings. Other finishes may include chemical treatments or laminations that offer improved abrasion resistance. Ultimately, the choice of fiberglass fabric finish for abrasion resistance will depend on the specific application and the level of protection required. Manufacturers and users of fiberglass fabrics should carefully consider the intended use and the potential wear and tear that the fabric may encounter in order to select the most appropriate finish for their needs.

- Q: Are fiberglass fabrics suitable for use in marine environments?

- Fiberglass fabrics prove to be highly suitable for utilization in marine environments due to their exceptional strength and durability, rendering them an ideal material for marine applications. With a resistance to corrosion, moisture, and UV rays that are frequently encountered in marine settings, fiberglass fabrics are renowned for their exceptional performance. Furthermore, these fabrics possess remarkable thermal and electrical insulation properties, further enhancing their practicality for marine use. Additionally, the flexible and efficient design options in boat building and repair are made possible by the ease with which fiberglass fabrics can be molded into various shapes and sizes. In summary, the combination of strength, durability, corrosion resistance, and versatility establishes fiberglass fabrics as an outstanding choice for marine environments.

- Q: What are the safety precautions when working with fiberglass fabric?

- When working with fiberglass fabric, it is important to take several safety precautions. Firstly, wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and a dust mask is essential to protect the skin, eyes, and respiratory system from potential irritants and fine particles. It is also crucial to work in a well-ventilated area or use a respirator to minimize the inhalation of fiberglass dust or fumes. To further prevent skin irritation or cuts, it is recommended to wear long sleeves, long pants, and closed-toe shoes. Additionally, avoiding contact with exposed skin and promptly washing any areas that come into contact with fiberglass fabric can help prevent irritation. When working with fiberglass fabric, it is important to handle it with care to avoid releasing fibers into the air. Cutting or sanding fiberglass materials should be done using tools with appropriate dust control measures, such as wet cutting or using a dust collection system. Properly disposing of waste material and cleaning up any fiberglass dust or debris is crucial to maintain a safe working environment. Overall, adhering to these safety precautions when working with fiberglass fabric can help minimize the risks associated with exposure to fiberglass particles and ensure a safer working environment.

- Q: How is fiberglass fabric used in the production of fire-resistant blankets?

- Due to its exceptional fire-resistant properties, fiberglass fabric plays a crucial role in the production of fire-resistant blankets. This fabric is made from woven glass fibers, which possess high resistance to heat and flames. To enhance its fire-resistant capabilities, fiberglass fabric is initially coated with a fire-resistant material or treated with a fire-retardant chemical during the production process. This treatment ensures that the fabric can withstand high temperatures and prevent the spread of fire. By layering multiple sheets of fiberglass fabric together, thick and durable fire-resistant blankets are manufactured. These blankets are sewn or bonded together to create a single unit, offering maximum protection. When exposed to fire, fiberglass fabric acts as an insulator, reflecting heat and preventing its transfer to the other side of the blanket. This effectively suppresses the spread of flames and reduces the risks of burns and injuries. Moreover, fiberglass fabric is lightweight and flexible, allowing for easy handling and maneuverability during emergency situations. Consequently, fire-resistant blankets made with fiberglass fabric find wide application in industries such as firefighting, oil and gas, manufacturing, and construction. They serve to safeguard workers, equipment, and valuable assets from fire hazards. Overall, the utilization of fiberglass fabric in the production of fire-resistant blankets ensures a high level of protection against heat and flames, effectively mitigating fire-related risks.

- Q: Can fiberglass fabric be used for gaskets and seals?

- Yes, fiberglass fabric can be used for gaskets and seals. It is a versatile material that offers high temperature resistance, chemical resistance, and durability, making it suitable for various sealing applications. Additionally, fiberglass fabric can be easily molded and cut to fit specific shapes and sizes, providing an effective barrier against leaks and ensuring a tight seal.

- Q: Can fiberglass fabric be used for making curtains or dividers?

- Fiberglass fabric is capable of being utilized in the creation of curtains or dividers. Its reputation lies in its durability, strength, and fire resistance, rendering it an appropriate material for these purposes. Additionally, it possesses a lightweight and flexible nature, facilitating effortless manipulation and installation. Furthermore, fiberglass fabric boasts easy cleaning and maintenance, making it a practical selection for curtains or dividers across diverse settings, including homes, offices, and industrial spaces.

- Q: Can fiberglass fabric be used for making signs and banners?

- Yes, fiberglass fabric can be used for making signs and banners. It is a durable and versatile material that can withstand outdoor conditions, making it suitable for various signage applications.

- Q: Can fiberglass fabric be used for insulation in steam systems?

- No, fiberglass fabric is not suitable for insulation in steam systems as it does not have the necessary heat resistance to withstand high temperatures.

- Q: Can fiberglass fabric be used for making automotive interiors?

- Yes, fiberglass fabric can be used for making automotive interiors. Fiberglass fabric is known for its strength, durability, and lightweight properties, making it an ideal material for various applications in the automotive industry. In automotive interiors, fiberglass fabric can be used for making seat covers, door panels, headliners, and various other components. It provides excellent resistance to wear and tear, is easy to clean, and offers a sleek and modern look. Additionally, fiberglass fabric can be molded into different shapes and sizes, allowing for customization and precise fitment in automotive interiors. Overall, fiberglass fabric is a versatile and reliable material choice for enhancing the aesthetics and functionality of automotive interiors.

- Q: Can fiberglass fabric be used for reinforcement in chemical processing tanks?

- Yes, fiberglass fabric can be used for reinforcement in chemical processing tanks. Fiberglass is highly resistant to corrosion and can withstand a wide range of chemicals, making it an ideal material for reinforcing tanks in chemical processing industries. It is lightweight, durable, and has excellent mechanical properties, making it suitable for withstanding the harsh conditions of chemical processing.

Send your message to us

Silicone Coated Fiberglass Scrim Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords