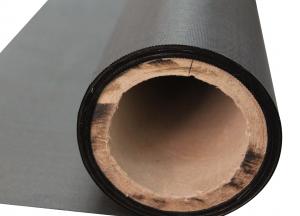

Fiberglass Facing Black Fiber Cloth BFC-160GSM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 100000M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

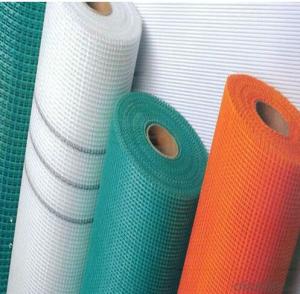

You Might Also Like

1. Specification of Black Fiberglass Cloth BFC-001 (EW160F)

|

Specification | ||

|

ITEM |

UNIT |

VALUE |

|

Weight |

g/m2 |

160 |

|

Thickness |

mm |

0.2 |

|

Density |

/cm |

12×12 |

|

Oxygen Index Number |

% |

≥32 |

|

Tensile Strength MD |

n/5cm |

800 |

|

Tensile Strength CMD |

n/5cm |

500 |

|

Fire Resistant Property |

|

B1 |

MSDS:No harm for body and environment, non-volatile product.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4. Good appearance without stain, oxidation, mildew.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

2. Application of Black Fiberglass Cloth BFC-001 (EW160F)

Fiberglass facing is good at fireproof, mildew resistant, damp proof and strong air permeability. After laminated with glass wool or rock wool, the physical properties is excellent such as hat preservation, noise elimination, fire retardant, extinction,etc.

3. Packaging & Delivery of Black Fiberglass Cloth BFC-001 (EW160F)

Depends on the clients' requirements and the production conditions.

- Q: Can black fiberglass tissues be utilized in creating decorative elements for indoor spaces?

- <p>Yes, black fiberglass tissues can be used to create decorative elements for interiors. Known for their durability and flexibility, they can be molded into various shapes and designs. They are often used in modern and industrial designs for their sleek appearance and strength. However, it's important to note that fiberglass may require special handling and installation due to its material properties, and it's advisable to consult with professionals to ensure safety and proper application in interior design.</p>

- Q: What is the chemical stability of black fiberglass tissue, and how does it react to various chemicals?

- <p>Black fiberglass tissue, which is a type of composite material made from glass fibers and a resin matrix, typically exhibits good chemical stability. It is resistant to many chemicals, including alkalis, acids, and salts, making it suitable for various industrial applications. However, it may not be as stable against strong acids or bases over extended periods. The stability can also be influenced by the specific type of resin used in the fiberglass, with some resins offering better resistance to certain chemicals than others. It's important to consult the material data sheet for specific information on chemical resistance for the black fiberglass tissue in question.</p>

- Q: This question asks for an explanation of how black fiberglass tissue is utilized across different sectors.

- <p>Black fiberglass tissue, also known as black glass fabric, is widely used in various industries due to its high strength, heat resistance, and electrical insulation properties. It is commonly applied in the electronics industry for printed circuit boards and insulation components. In the construction sector, it is used for reinforcing materials in concrete and as a fire-resistant barrier. The automotive industry utilizes it for heat shields and electrical components. Additionally, it is employed in aerospace for lightweight, high-strength components and in the marine industry for corrosion-resistant applications. Overall, black fiberglass tissue enhances product performance and durability in a multitude of applications.</p>

- Q: Is it appropriate to utilize black fiberglass tissues for cleaning up liquid spills on hard surfaces?

- <p>Yes, you can use black fiberglass tissues for wiping up spills on hard surfaces. They are designed to be strong and absorbent, making them suitable for cleaning up liquids. However, it's important to ensure that the hard surface is not damaged by the abrasiveness of the fiberglass. Always test on a small, inconspicuous area first to confirm it's safe. Additionally, be cautious as black tissues may leave fibers or color transfer on light-colored surfaces.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other sound insulation materials, focusing on their properties and effectiveness.

- <p>Black fiberglass tissue is a type of sound insulation material known for its lightweight, flexibility, and high sound absorption capabilities. Compared to other materials, it offers excellent thermal insulation and resistance to moisture and fire. However, it may not be as dense or heavy-duty as some alternatives like mass-loaded vinyl or certain types of acoustic foam, which can provide better soundproofing in high-noise environments. Black fiberglass tissue is also sensitive to physical damage, which can reduce its effectiveness over time. It's important to consider the specific application and environmental factors when choosing the right sound insulation material.</p>

- Q: Is it possible to utilize black fiberglass tissue as a flooring material in residential settings?

- <p>Yes, black fiberglass tissue can be used for flooring in residential homes. It is known for its durability, resistance to moisture and chemicals, and is often used in areas prone to water or chemical exposure. However, it may not be as aesthetically pleasing as traditional flooring options and can be slippery when wet, so it's important to consider these factors when deciding on its use for residential flooring.</p>

- Q: This question asks about the distinctions among various types of glass fiber paper, which are materials made from thin strands of glass.

- <p>Different types of glass fiber paper are distinguished by their composition, manufacturing processes, and applications. E-glass is the most common and is used for general purposes due to its good electrical insulation properties. S-glass, known for its high strength, is used in applications requiring mechanical strength, such as in aircraft and sports equipment. C-glass is resistant to chemical corrosion and is used in environments with harsh chemicals. A-glass, or alumino-borosilicate glass, is used for applications requiring high temperature resistance. Lastly, D-glass is designed for low dielectric applications, making it suitable for electronics. Each type has unique properties that make it suitable for specific industries and applications.</p>

- Q: Is it safe to use black fiberglass tissue in a kitchen environment, considering factors such as heat, moisture, and potential health risks?

- <p>Black fiberglass tissue is generally not recommended for use in a kitchen environment due to its potential to release glass fibers, which can be harmful if inhaled or ingested. Kitchens have high heat and moisture levels, which can degrade the fiberglass, leading to the release of these fibers. Additionally, the black color may not be suitable for surfaces that come into contact with food. It's safer to use materials specifically designed for kitchen use that are heat and moisture resistant and do not pose health risks.</p>

- Q: Is it possible to use black fiberglass tissue as a material for creating a bedspread or blanket?

- <p>While it is technically possible to use black fiberglass tissue to create a bedspread or blanket, it is not recommended. Fiberglass is a type of plastic material known for its strength and insulation properties, but it is not designed for comfort or direct contact with the skin. It can be rough and may cause skin irritation. Traditional bedding materials like cotton, wool, or synthetic fibers are softer, more comfortable, and better suited for use in bedspreads and blankets.</p>

- Q: What benefits does black fiberglass tissue offer compared to other types of tissues?

- <p>Black fiberglass tissues offer several advantages over other types. They have excellent resistance to high temperatures, making them suitable for use in high-heat environments. They also provide superior electrical insulation properties, which is crucial in electrical applications. Additionally, black fiberglass tissues are known for their chemical resistance, which protects against various chemicals that could degrade other materials. Their strength and durability make them ideal for applications requiring long-lasting performance. Lastly, the black color can provide a more aesthetically pleasing appearance in certain industrial settings.</p>

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$0.3 billion |

| Main Markets | 0.00% Mid East 15.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe 0South east asia;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Facing Black Fiber Cloth BFC-160GSM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 100000M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords