Fiberglass Fabrics with Thermal Insulation Silicone Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Silicone coated fiberglass fabric is made by special formulated liquid or wet silicone rubber dispersed or calendered into the high quality fiberglass cloth and vulcanized, dried. This finished silicone fabric inherits the fiberglass insulation fabric's properties and also improve its fireproof, hand fabrication, oil and waterproof, abrasion resistance.

Features: Fireproof, Thermal Insulation, Abrasion Resistance, Waterproof

Application: Thermal Insulation Cover, Blanket, Jacket, Cover, Pad, Fabric Expansion Joint, Flexible Connector, Welding Blanket, Fire Blanket, Fireproof Curtain, Smoke Curtain

PRICE: USD3.5 per square meter

UNIT: square meter

MOQ: 500 square meter

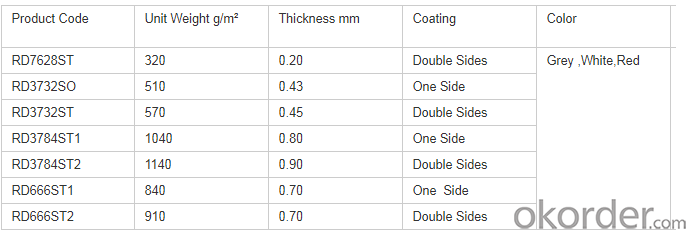

Weight: 140gsm-3000gsm

Width: 90mm to 2000mm or customized

Yarn Type: E-glass

Standing temperature -50℃-550℃

Product name: Silicone Coated Fiberglass Fabric

Coating/Finish/Surface Treatment: Silicone coated

Roll length: 50 meter or customized

Color: Grey, Red, Black, White, Salmon, Green, Blue, Yellow, or customized

Weave Type: Twill, Satin, plain woven or customized

Alkali content: alkali free

Processing service: cutting

Material: fiberglass

Thickness: 0.1mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: How is fiberglass fabric used in the packaging industry?

- Fiberglass fabric is widely used in the packaging industry for various purposes. It is known for its strength, durability, and heat resistance properties, making it an ideal material for packaging applications. One of the primary uses of fiberglass fabric in the packaging industry is as a reinforcement material. It is often used to reinforce cardboard boxes, crates, and other packaging materials to increase their load-bearing capacity. By adding a layer of fiberglass fabric, the packaging becomes more robust and can withstand heavier loads without getting damaged. Fiberglass fabric is also commonly used as a protective lining or wrapping material. It can be used to line the inside of packaging containers, such as drums or barrels, to provide an additional layer of protection. This helps to prevent any leakage or damage to the contents during transportation or storage. Furthermore, fiberglass fabric is utilized for insulation purposes in the packaging industry. It is commonly used to insulate packaging materials that need to maintain a specific temperature, such as cold chain packaging for perishable goods or thermal insulation for sensitive electronics. The heat resistance property of fiberglass fabric helps in maintaining the desired temperature inside the packaging, ensuring the safety and quality of the products. Additionally, fiberglass fabric is also used as a barrier material in the packaging industry. It can be used to create a moisture or vapor barrier by laminating it with other materials. This helps to protect the packaged goods from moisture, humidity, or other external factors that could potentially damage them. In summary, fiberglass fabric is extensively used in the packaging industry for reinforcement, protective lining, insulation, and barrier purposes. Its strength, durability, heat resistance, and insulating properties make it an excellent choice for various packaging applications, ensuring the safety and integrity of the packaged goods.

- Q: Construction method of organosilicon waterproof coating

- Basic level treatment: the surface of the base layer is required to be smooth, and uneven sand lifting is not allowed.

- Q: Can fiberglass fabric be used for making filters for air purifiers?

- Yes, fiberglass fabric can be used for making filters for air purifiers. Fiberglass is a commonly used material in air filtration due to its high efficiency in capturing small particles and its durability. It can effectively trap dust, pollen, and other airborne contaminants, making it suitable for air purification purposes.

- Q: Can fiberglass fabric be used for insulation in breweries?

- Yes, fiberglass fabric can be used for insulation in breweries. Fiberglass fabric is known for its excellent insulation properties, as it has a low thermal conductivity and high resistance to heat transfer. This makes it an ideal material for insulating various applications, including breweries. Insulation in breweries is crucial to maintain specific temperature conditions for various processes involved in brewing, such as fermentation, mashing, and boiling. Fiberglass fabric can be used to insulate brewing vessels, pipes, and tanks, ensuring that heat is retained or prevented from entering the system, depending on the specific requirement. Fiberglass fabric is also resistant to moisture, which is essential in brewery environments where there may be high humidity levels or exposure to liquids. It does not absorb moisture, ensuring that its insulation properties are not compromised over time. Additionally, fiberglass fabric is easy to install and can be customized to fit different sizes and shapes, making it a versatile choice for insulation in breweries. It is lightweight and flexible, allowing for easy handling and installation in various areas of the brewery. Overall, fiberglass fabric is a suitable choice for insulation in breweries due to its excellent thermal insulation properties, moisture resistance, and ease of installation. It helps maintain optimal temperature conditions, improving energy efficiency and ensuring the quality of the brewing process.

- Q: Are fiberglass fabrics suitable for use in the energy sector?

- Yes, fiberglass fabrics are suitable for use in the energy sector. They offer excellent thermal insulation properties, are resistant to high temperatures, and have high strength and durability. Fiberglass fabrics are commonly used in insulation systems, electrical insulation, and as a reinforcement material in composite structures, making them well-suited for various applications in the energy sector.

- Q: What are the different fiberglass fabric weaves for impact resistance?

- There are several different fiberglass fabric weaves that are known for their impact resistance. Some of the common weaves include plain weave, twill weave, satin weave, and leno weave. Each weave has its own unique characteristics and advantages when it comes to providing impact resistance in fiberglass fabrics.

- Q: What are the different fiberglass fabric coatings for corrosion resistance?

- There are several different types of fiberglass fabric coatings available for corrosion resistance. Some of the most commonly used coatings include: 1. Silicone: Silicone coatings provide excellent resistance to corrosion, as well as high temperatures. They are often used in harsh environments where chemical exposure and extreme temperatures are a concern. 2. Polyurethane: Polyurethane coatings offer superior chemical resistance, making them suitable for applications where exposure to corrosive substances is common. They also provide good abrasion resistance and can withstand harsh weather conditions. 3. Epoxy: Epoxy coatings are known for their exceptional adhesion and chemical resistance properties. They are often used in marine and offshore industries where exposure to saltwater and other corrosive elements is prevalent. 4. Vinyl ester: Vinyl ester coatings are highly resistant to chemicals, acids, and alkalis. They are commonly used in applications where there is a need for superior resistance against corrosion, such as in the chemical processing industry. 5. Polyester: Polyester coatings provide good resistance to corrosion and UV radiation. They are often used in outdoor applications where exposure to sunlight and weather conditions can lead to degradation. Each of these fiberglass fabric coatings has its own unique properties and advantages, and the choice of coating depends on the specific requirements of the application. It is important to carefully consider factors such as the type of corrosive substances present, temperature conditions, and the desired lifespan of the coating before selecting the appropriate fiberglass fabric coating for corrosion resistance.

- Q: How is fiberglass fabric used in the environmental industry?

- Fiberglass fabric is commonly used in the environmental industry for various applications. It is often used as a reinforcement material in the construction of pollution control equipment, such as scrubbers and filters, due to its high strength and corrosion resistance. Additionally, fiberglass fabric is used to manufacture geotextiles, which are used for erosion control, soil stabilization, and landfill liners. Its durability and ability to withstand harsh environmental conditions make it a valuable material in the environmental industry.

- Q: Can fiberglass fabric be used for insulation in HVAC ducts?

- Yes, fiberglass fabric can be used for insulation in HVAC ducts. Fiberglass fabric is a commonly used material for insulating HVAC ducts due to its excellent thermal insulation properties. It helps to prevent heat loss or gain by providing a barrier between the ducts and the surrounding environment. Additionally, fiberglass fabric is lightweight, flexible, and easy to install, making it an ideal choice for insulating ductwork. It can effectively reduce energy consumption and improve the overall efficiency of HVAC systems. Moreover, fiberglass fabric is resistant to high temperatures, moisture, and chemicals, ensuring long-term durability and performance in HVAC applications.

- Q: Can fiberglass fabrics be used for insulation purposes?

- For insulation purposes, fiberglass fabrics are a suitable option. These fabrics consist of extremely fine glass fibers that are woven together, resulting in a material that is lightweight and flexible. The excellent insulation properties of this fabric are due to its ability to trap air and prevent the transfer of heat or cold. Commonly used in insulation applications, fiberglass fabrics are employed for insulating pipes, ducts, walls, and roofs. They are also utilized in the production of thermal blankets and curtains designed for insulation purposes. Moreover, fiberglass fabrics can be combined with other insulating materials to enhance their overall effectiveness. One of the main advantages of using fiberglass fabrics for insulation is their high thermal resistance. With a low thermal conductivity, these fabrics can significantly reduce heat transfer and maintain stable temperatures in insulated areas. Additionally, fiberglass fabrics are non-combustible and exhibit good resistance to moisture and chemicals, making them suitable for a wide range of insulation applications. Furthermore, fiberglass fabrics are easy to handle and install. They can be easily cut and shaped to fit specific dimensions, and can be attached to surfaces using mechanical fasteners or adhesive. Due to their flexibility and ease of installation, fiberglass fabrics are a popular choice for insulation projects in both residential and commercial settings. To conclude, fiberglass fabrics are an excellent option for insulation purposes. Their high thermal resistance, durability, and ease of installation make them a versatile and effective solution for various insulation applications.

Send your message to us

Fiberglass Fabrics with Thermal Insulation Silicone Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords