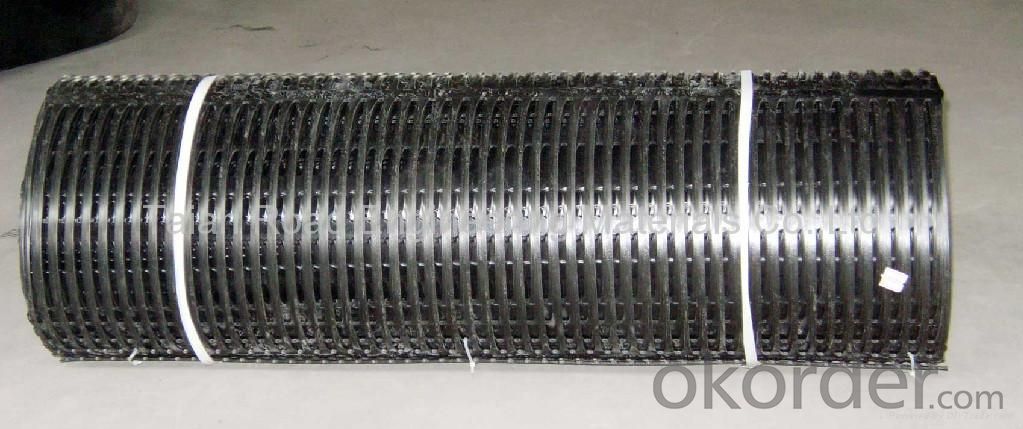

Fiberglass Fabrics from Malaysia Supplier - Fiberglass Geogrid for Airport Road Protection - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

4.FAQ

3 No long-term creep : as a reinforcing material , with the ability to resist deformation under the load in the long-term creep resistance is extremely important, the glass fiber will not creep , to ensure that the products can long-term performance .

- Q: Can fiberglass fabric be used for reinforcement in concrete pipes?

- Certainly! Fiberglass fabric proves to be an excellent option for reinforcing concrete pipes due to its robustness and lightweight nature, as well as its resistance to corrosion. By incorporating this material, concrete structures, including pipes, acquire enhanced strength and durability, resulting in an increased capacity to bear loads and a decreased likelihood of cracks or breakdowns. Moreover, the favorable thermal and chemical resistance properties of fiberglass fabric further solidify its appropriateness for reinforcing concrete pipes.

- Q: How does fiberglass fabric perform in cryogenic applications?

- Fiberglass fabric performs well in cryogenic applications due to its excellent thermal insulation properties and resistance to extreme cold temperatures. It maintains its structural integrity and does not become brittle or lose its strength when exposed to cryogenic conditions. Additionally, fiberglass fabric has low thermal conductivity, which helps to minimize heat transfer in cryogenic environments.

- Q: What is the best waterproof material for swimming pool?

- Waterproof: waterproof material and supporting adhesive in the inside of the swimming pool and the pool bottom covered with 2~3 layer, and then re tiling surface;

- Q: How does fiberglass fabric perform in terms of dimensional stability?

- Fiberglass fabric offers excellent dimensional stability due to its inherent strength and rigidity. It is resistant to stretching, shrinking, and warping, making it an ideal choice for applications where maintaining shape and size is crucial.

- Q: Can fiberglass fabric be used in automotive applications?

- Yes, fiberglass fabric can be used in automotive applications. Fiberglass is a versatile material known for its strength, durability, and heat resistance. It is commonly used in various automotive components such as body panels, hoods, fenders, and interior parts. Fiberglass fabric can be molded into complex shapes and has excellent structural properties, making it suitable for automotive applications where strength and lightweight design are crucial. Additionally, fiberglass fabric can be easily painted and provides a smooth finish, enhancing the aesthetic appeal of automotive parts. Overall, fiberglass fabric is a popular choice in the automotive industry due to its versatility, strength, and ability to meet the demanding requirements of automotive applications.

- Q: How is fiberglass fabric recycled?

- Fiberglass fabric recycling is a multi-step process that involves various techniques and technologies to transform used or waste fiberglass materials into new products. The recycling process typically includes the following steps: 1. Collection: The first step in recycling fiberglass fabric is to collect the waste materials. This can be done through various means, such as waste management systems, industrial recycling programs, or specialized collection centers. 2. Sorting: Once collected, the fiberglass fabrics are sorted based on their type, color, and condition. This helps in determining the appropriate recycling methods and potential applications for the recycled material. 3. Shredding: The sorted fiberglass fabrics are then shredded into smaller pieces or fibers. This makes it easier to handle and process the material in subsequent steps. 4. Cleaning: The shredded fiberglass is thoroughly cleaned to remove any contaminants or impurities. This is typically done through a process called washing, which uses water and detergents to ensure the material is free from any residues. 5. Resizing: After cleaning, the fiberglass fibers may go through a resizing process to achieve a uniform length or size. This step is important for ensuring consistency in the final product. 6. Melting: The resized fiberglass fibers are then melted down using high temperatures. This process, known as melting or liquefying, transforms the fibers into a molten state, which makes them easier to manipulate and mold. 7. Reinforcement: Once melted, the fiberglass can be used as a reinforcing material. It is often combined with resins, such as polyester or epoxy, to create composite materials commonly used in various industries, including construction, automotive, and aerospace. 8. Molding: The molten fiberglass-resin mixture is then molded into desired shapes or forms using techniques like injection molding, compression molding, or pultrusion. This allows the recycled fiberglass to be transformed into new products, such as insulation, panels, pipes, or even sporting goods. 9. Final Processing: After molding, the newly formed fiberglass products may undergo additional processes, such as curing, cooling, or surface finishing, to enhance their properties and ensure their quality. 10. Market Distribution: Finally, the recycled fiberglass products are packaged and distributed to the market, where they can be purchased and utilized by various industries and consumers. Overall, fiberglass fabric recycling is an intricate process that aims to repurpose and transform waste materials into valuable products, reducing the environmental impact of fiberglass waste and promoting a more sustainable approach to manufacturing and consumption.

- Q: How do fiberglass fabrics perform in terms of chemical resistance?

- Fiberglass fabrics have excellent chemical resistance properties, making them highly resistant to a wide range of chemicals. They can withstand exposure to acids, bases, solvents, and other corrosive substances without significant degradation or damage. This makes fiberglass fabrics a suitable choice for various applications where chemical resistance is critical, such as in the manufacturing of protective clothing, chemical storage tanks, and filtration systems.

- Q: Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Indeed, reinforcement in underground storage tanks can be achieved through the utilization of fiberglass fabric. Renowned for its exceptional corrosion resistance and high strength-to-weight ratio, fiberglass fabric emerges as an optimal selection for this purpose. The incorporation of fiberglass fabric not only enhances the structural integrity of the tank but also mitigates the risk of potential failures or leaks. Additionally, the ease of handling and installation of fiberglass fabric renders it a practical and cost-efficient solution for reinforcing underground storage tanks.

- Q: How does fiberglass fabric perform in puncture resistance?

- Fiberglass fabric is known for its excellent puncture resistance. It is highly durable and can withstand piercing or tearing forces, making it a reliable choice for applications where puncture resistance is crucial, such as protective clothing, industrial equipment, and aerospace components.

- Q: What cloth is used for the anticorrosion of fire pipes?

- Use glass fiber cloth, three oil, two cloth, anticorrosive.

Send your message to us

Fiberglass Fabrics from Malaysia Supplier - Fiberglass Geogrid for Airport Road Protection - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords