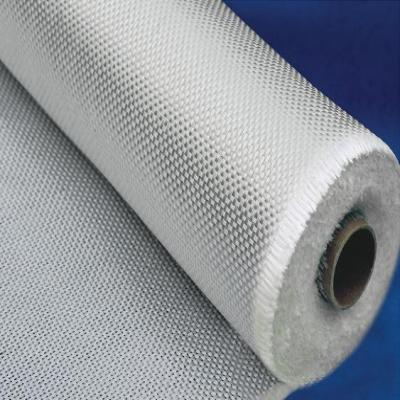

Fiberglass Fabrics - e-glass fiber woven fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 400ton kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

E-glss fiber woven roving is bidirectional fabric made by interweaving direct roving.

Woven Roving are compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. Woven Roving are high-performance reinforcement widely used in hand lay-up and robot processes for the production of boats, vessels, plane and automotive parts, Pipe, furniture and sports facilities.

2.Characteristics

Top quality woven rovng fabric, E or C glass product

Woven roving fabric is bidirectional fabric made by interweaving direct roving. E-Glass Woven Roving is compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. E-glass Woven Roving is a high-performance reinforcement widely used in hand lay up and robot processes for the production of boats, vessels, plane and automotive parts, furniture and sports facilities.

Product Features:

1. Warp and weft roving aligned in a parallel and flat manner, resulting in uniform tension.

2. Densely aligned fibers, resulting in high dimensional stability and making handing easy.

3. Good mold ability, fast and complete wet in resins, resulting in high productivity.

4. Good transparency and high strength of composite products.

3.Product Specifications

Items: | Warp Tex | Weft Tex | Warp Density | Woft Density | Weight | Combustible |

Ends/cm | Ends/cm | g/m2 | Content(%) | |||

WRE260 | 600 | 600 | 2.2 | 2.2 | 251-277 | 0.4-0.8 |

WRE270 | 300 | 300 | 4.6 | 4.1 | 248-274 | 0.4-0.8 |

WRE300 | 600 | 600 | 3.2 | 1.8 | 296-328 | 0.4-0.8 |

WRE360 | 600 | 900 | 3.2 | 1.8 | 336-372 | 0.4-0.8 |

WRE400A | 600 | 600 | 3.2 | 3.8 | 400-440 | 0.4-0.8 |

WRE400B | 600 | 900 | 3.2 | 2.3 | 380-420 | 0.4-0.8 |

WRE500A | 1200 | 1200 | 2.2 | 2.0 | 475-525 | 0.4-0.8 |

WRE500B | 1200 | 1750 | 2.0 | 1.6 | 495-545 | 0.4-0.8 |

WRE500T | 1200 | 1200 | 2.2 | 2.2 | 500-554 | 0.4-0.8 |

WRE550 | 1530 | 1200 | 2.0 | 2.0 | 520-570 | 0.4-0.8 |

WRE580 | 1200 | 1200 | 2.6 | 2.2 | 550-610 | 0.4-0.8 |

WRE600B | 2200 | 1200 | 2.0 | 1.6 | 600-664 | 0.4-0.8 |

WRE600C | 1290 | 1290 | 2.8 | 2.0 | 588-650 | 0.4-0.8 |

WRE600D | 1530 | 1530 | 2.0 | 2.0 | 580-642 | 0.4-0.8 |

WRE800A | 1200*2 | 1200*2 | 2.0 | 1.5 | 800-880 | 0.4-0.8 |

WRE800B | 2400 | 2400 | 2.0 | 1.6 | 820-908 | 0.4-0.8 |

WRE800C | 1750 | 1750 | 2.8 | 2.0 | 800-880 | 0.4-0.8 |

WRE800D | 1200*2 | 1530*2 | 2.0 | 1.2 | 806-890 | 0.4-0.8 |

WRE800T | 2400 | 1750 | 2.0 | 2.0 | 790-870 | 0.4-0.8 |

WRE1200A | 4000*2 | 4400 | 0.8 | 1.4 | 1190-1320 | 0.4-0.8 |

WRE1200B | 2400*2 | 2400*2 | 1.4 | 1.2 | 1190-1310 | 0.4-0.8 |

4.FAQ

Packaging & Delivery

Packaging Details: | Poly bag, then loading into carton box |

Delivery Detail: | 20 days after confirm order |

- Q: Is fiberglass fabric resistant to chemical degradation?

- Yes, fiberglass fabric is generally resistant to chemical degradation.

- Q: What is the heat resistance of fiberglass fabric?

- Fiberglass fabric boasts a remarkable resistance to heat, enabling it to endure temperatures as high as 1000 degrees Fahrenheit (537 degrees Celsius) without experiencing notable harm or deterioration. This outstanding characteristic renders it an exceptional selection for various purposes that entail exposure to extreme heat, including welding blankets, insulation materials, and fire-resistant clothing. Moreover, fiberglass fabric exhibits a low thermal conductivity, signifying its limited ability to conduct heat effectively, thereby offering an extra shield of defense in environments with elevated temperatures.

- Q: What is the difference between non-woven fabrics, glass fiber cloth and geotextile?

- The exact name of the non-woven fabric shall be nonwoven or non-woven. Because it is a kind of form that does not require spinning weaving fabric, just a textile fiber or filament aligned or random, the formation of the fiber network structure, and then the mechanical, thermal or chemical methods and strengthening into. Nonwovens break through the traditional textile principle, and have the characteristics of short process flow, fast production, high yield, low cost, wide use and many sources of raw materials.

- Q: What are the different applications of fiberglass fabric in the oil and gas industry?

- Fiberglass fabric finds various applications in the oil and gas industry due to its excellent properties such as high strength, corrosion resistance, and thermal insulation. It is commonly used for insulation, fireproofing, and reinforcement purposes in pipelines, tanks, and equipment. Fiberglass fabric is also utilized for manufacturing composite materials in the form of pipes, gratings, and platforms, providing durability and resistance to chemicals and harsh environments. Overall, its versatility and reliability make it an essential material for enhancing safety and performance in the oil and gas sector.

- Q: Can fiberglass fabric be used for reinforcement in aerospace components?

- Certainly, fiberglass fabric finds application as reinforcement in aerospace components. Fiberglass, a material known for its lightweight and robust nature, has been extensively utilized in the aerospace sector for numerous years. It boasts exceptional mechanical properties, encompassing remarkable tensile strength, stiffness, corrosion resistance, and fatigue resistance. These attributes render fiberglass fabric an optimal selection for reinforcing aerospace components like fuselages, wings, and structural elements. Moreover, the malleability of fiberglass fabric facilitates effortless molding into intricate forms, thus enabling enhanced design adaptability in aerospace applications. In summary, fiberglass fabric emerges as a dependable and economical reinforcement material in the aerospace industry.

- Q: Can fiberglass fabric be used for clothing?

- Yes, fiberglass fabric can be used for clothing. However, it is not commonly used for this purpose due to its abrasive and rigid nature, which can cause discomfort and potential skin irritation. Additionally, fiberglass fabric does not provide adequate breathability or flexibility required for comfortable clothing.

- Q: Can fiberglass fabric be used for insulation sleeves?

- Yes, fiberglass fabric can be used for insulation sleeves. It has excellent thermal insulation properties, is fire-resistant, and can withstand high temperatures, making it an ideal choice for insulating sleeves.

- Q: What is the average thickness of fiberglass fabric?

- Depending on the specific application and manufacturing process, the average thickness of fiberglass fabric can vary. Typically, the thickness of fiberglass fabric ranges from 0.2 millimeters (0.008 inches) to 0.5 millimeters (0.02 inches).

- Q: Are there any specific storage requirements for fiberglass fabrics?

- Fiberglass fabrics have specific storage requirements. It is highly advised to keep them in a cool, dry, and well-ventilated place to prevent moisture absorption and potential fabric damage. To avoid degradation of strength and appearance, it is crucial to store them away from direct sunlight, as prolonged exposure to UV rays can be harmful. Furthermore, it is vital to keep the fabrics far from heat sources or open flames to minimize the risk of fire. Additionally, it is essential to store them separately from chemicals, solvents, or oils that may cause staining or deterioration. By storing fiberglass fabrics properly, their quality and lifespan can be maintained.

- Q: Can fiberglass fabric be used for making awnings?

- Yes, fiberglass fabric can be used for making awnings. Fiberglass is a durable and lightweight material that is resistant to weather conditions, making it suitable for outdoor applications like awnings. It is also easy to clean and maintain, making it a popular choice for awning construction.

Send your message to us

Fiberglass Fabrics - e-glass fiber woven fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 400ton kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords