Fiberglass Corrugated Roofing Sheet Used in Construction with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 222 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

Composition | UP-resin system, glass fiber , gel coat or protective film |

Surface | Dupon 20um Film or Gel Coat |

Fiber Content | 25% - 35%, using JUSHI fiber |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm |

Width | Up to 1.35 meter |

Effective temperature | -40℃~ +120℃ |

Light Transmissivity | 3% - 85% |

Length | Customizable, for easy transport, suggest using 5.6m or 11.8m |

Profile | Flat type & corrugated type, LG840, LG900, LG1050 or customizable |

Colors | Clear blue, Light blue, Lake blue, Sky blue, Deep blue, Clear white, Solid white, Gray white, Black, Clear green or Customizable |

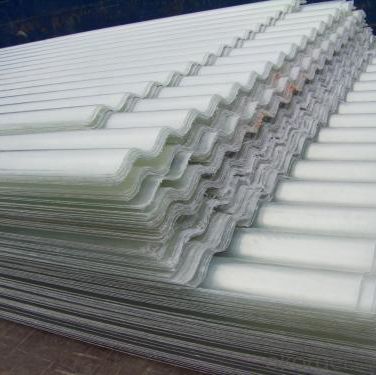

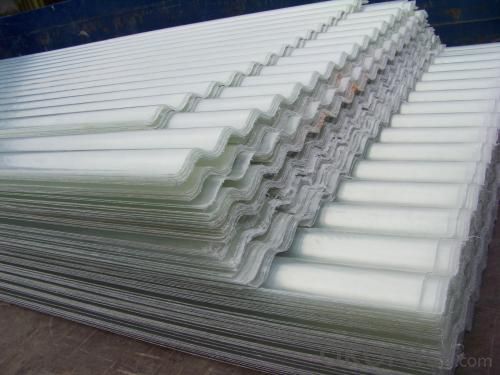

PICTURES

- Q: Can FRP roofing panels be used in both residential and commercial applications?

- Yes, FRP (fiberglass reinforced plastic) roofing panels can be used in both residential and commercial applications. FRP panels are known for their durability, strength, and longevity, making them suitable for a wide range of applications. In residential settings, FRP panels can be used for roofs, skylights, carports, or patio covers. They provide protection against harsh weather conditions, such as extreme temperatures, UV radiation, and heavy rainfall. Similarly, in commercial applications, FRP roofing panels are commonly used for warehouses, factories, agricultural buildings, and commercial buildings such as shopping centers or office complexes. They offer excellent resistance to corrosion, chemicals, and fire, making them a reliable choice for commercial structures. Moreover, FRP panels come in various profiles, colors, and sizes, allowing for customization to suit the specific requirements of any residential or commercial project. They are lightweight, easy to install, and require minimal maintenance. Additionally, FRP panels have good insulation properties, which can contribute to energy efficiency in both residential and commercial buildings. Overall, FRP roofing panels are versatile and can be used effectively in both residential and commercial applications, providing durability, strength, and protection against environmental elements.

- Q: Are FRP roofing panels suitable for university campuses or educational buildings?

- Yes, FRP roofing panels are suitable for university campuses or educational buildings. FRP (Fiberglass Reinforced Plastic) roofing panels offer numerous benefits such as durability, lightweight construction, resistance to extreme weather conditions, and low maintenance requirements. These factors make FRP roofing panels a reliable and cost-effective choice for educational institutions seeking long-lasting and sustainable roofing solutions.

- Q: Can FRP roofing panels be used in schools or educational institutions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in schools or educational institutions. FRP roofing panels offer several advantages that make them suitable for such environments. Firstly, FRP panels are lightweight yet durable, making them easy to install and maintain. They are also resistant to UV radiation, corrosion, and chemical exposure, ensuring a longer lifespan and reduced maintenance costs. Additionally, FRP panels provide excellent insulation properties, helping to regulate temperature and reduce energy consumption in schools. Furthermore, these panels are fire-resistant, which is crucial for ensuring the safety of students and staff. Lastly, FRP roofing panels come in a variety of colors and designs, allowing educational institutions to choose a style that aligns with their aesthetic preferences. Overall, FRP roofing panels are a reliable and ideal choice for schools and educational institutions due to their durability, safety features, energy efficiency, and aesthetic versatility.

- Q: Are FRP roofing panels resistant to high winds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to high winds. The strength and durability of FRP panels make them capable of withstanding strong winds without getting damaged or blown away. The fiberglass reinforcement in the panels adds extra strength and stiffness, making them more resistant to wind uplift. Additionally, FRP panels are often installed with proper fastening systems, such as screws or clips, to secure them firmly to the structure. This further enhances their resistance to high winds. However, it is important to note that the specific wind resistance of FRP roofing panels may vary depending on factors such as the panel thickness, installation method, and the specific wind load requirements of the building code in the area. Therefore, it is advisable to consult with the manufacturer or a roofing professional to ensure that the FRP panels chosen are suitable for the specific wind conditions in the location where they will be installed.

- Q: Are FRP roofing panels suitable for recreational vehicles?

- Recreational vehicles can benefit from using FRP (Fiberglass Reinforced Panels) roofing panels. These panels, made from a blend of fiberglass and resin, offer a lightweight yet strong solution. Their ability to withstand corrosion, UV rays, and harsh weather conditions is crucial for RVs, which are frequently exposed to the elements. In addition, FRP roofing panels provide excellent insulation, effectively regulating the RV's interior temperature during hot or cold weather. This greatly enhances comfort during long journeys. Furthermore, the installation and maintenance of FRP panels are hassle-free. They can be easily customized to fit specific dimensions and shapes, allowing for flexibility during the installation process. Moreover, their resistance to mold, mildew, and rot ensures that the RV roof will have a longer lifespan. In summary, the lightweight nature, durability, weather resistance, insulation properties, and ease of installation and maintenance make FRP roofing panels an excellent choice for recreational vehicles.

- Q: Are FRP roofing panels easy to install?

- Yes, FRP roofing panels are relatively easy to install. They are lightweight and can be easily handled and maneuvered during installation. Additionally, they often come with pre-drilled holes and grooves for easy attachment to the roof structure. Overall, with proper guidance and tools, the installation process can be straightforward for both professionals and DIY enthusiasts.

- Q: Can FRP roofing panels be used in curved or domed roofs?

- FRP roofing panels are capable of being utilized in roofs that are curved or domed. These panels possess a flexible nature, enabling them to be effortlessly molded or shaped to accommodate diverse roof designs, such as curved or domed structures. The pliability of FRP permits it to be bent or curved without compromising its structural integrity. Consequently, FRP roofing panels are an ideal selection for architectural designs necessitating curved or domed roofs. Furthermore, these panels provide exceptional durability, weather resistance, and UV protection, establishing them as a dependable choice for numerous roofing applications.

- Q: Do FRP roofing panels require a specific type of roof anchor or tie-off system?

- FRP roofing panels must be secured with a specialized roof anchor or tie-off system due to their lightweight nature and smooth surface, which makes them vulnerable to wind uplift and potential damage. To ensure proper installation and safety, it is important to use a system specifically designed for FRP roofing panels. One commonly used system for FRP roofing panels is a mechanical fastening system. This involves using screws or nails along with appropriate washers and flashing materials to secure the panels to the roof substrate. The manufacturer's recommendations should be followed regarding the placement of the fasteners to ensure proper attachment and prevent panel movement. Using a sealant or adhesive compatible with FRP panels is also essential to enhance strength and weather resistance. This helps prevent water infiltration and reduces the risk of leaks or damage. Manufacturer guidelines and recommendations for the specific FRP roofing panels should be consulted to determine the appropriate roof anchor or tie-off system. Following these guidelines is crucial to meet industry standards and ensure the long-lasting performance of the FRP roofing system. While FRP roofing panels offer durability and resistance to corrosion, it is crucial to use a specific roof anchor or tie-off system for proper installation and safety. Consulting the manufacturer's guidelines and recommendations is necessary to select the appropriate system and ensure the success of the roofing project.

- Q: Can FRP roofing panels be used for skylights in museums?

- Skylights in museums can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess lightweight, durable attributes and exceptional light transmission properties, making them well-suited for skylight purposes. By allowing natural light to illuminate museum spaces, the reliance on artificial lighting can be reduced, resulting in a more visually appealing environment for visitors. Moreover, FRP panels are resistant to UV radiation and can be manufactured with various coatings and finishes to regulate light transmission, glare, and heat gain. Thus, the skylight panels can meet the specific requirements of the museum, protecting delicate artwork or artifacts from excessive light exposure. Ultimately, FRP roofing panels provide an efficient and visually pleasing solution for skylights in museums.

- Q: What is an FRP roofing panel?

- An FRP roofing panel refers to a roofing material made of Fiberglass Reinforced Plastic. It is a durable and lightweight panel that provides excellent strength, corrosion resistance, and weatherproofing for commercial and industrial buildings.

Send your message to us

Fiberglass Corrugated Roofing Sheet Used in Construction with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 222 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords