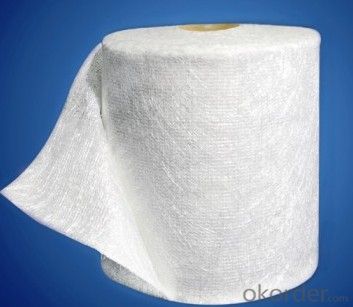

Fabric for Fiberglass Speaker Box - Fiber Glass Stitched Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

| (g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What are fiberglass fabrics made of?

- Fiberglass fabrics are made of thin strands of glass, typically composed of silica, which are woven together to form a flexible and durable material.

- Q: Can fiberglass fabric be used for making gloves?

- Yes, fiberglass fabric can be used for making gloves.

- Q: Can fiberglass fabric be used for reinforcement in aerospace components?

- Yes, fiberglass fabric can be used for reinforcement in aerospace components. It is often used in the manufacturing of composite materials for aircraft structures, providing high strength-to-weight ratio and excellent resistance to corrosion and fatigue.

- Q: XHJ how about neoprene asphalt waterproof coating?

- Wait for a paint, do solid work (usually for a day, summer for half a day), edge brush, paving and sticking glass fiber cloth, its work method is as follows:The paint evenly on the first line of work has the base brush, will have a glass fiber cloth placed on the top surface, gradually rolling launched just brush the paint on the brush, then stained with paint in has pasted the fiberglass cloth evenly, the glass fiber cloth firmly stuck on the base, and the entire fabric of the upper and lower diffuse full paint, paint together, to ensure the waterproof effect.

- Q: Can fiberglass fabrics be used for insulation in industrial machinery?

- Yes, fiberglass fabrics can be used for insulation in industrial machinery. Fiberglass fabrics are known for their excellent thermal insulation properties due to their low thermal conductivity. They have high resistance to heat transfer, making them a suitable choice for insulating industrial machinery that operates at high temperatures. Additionally, fiberglass fabrics are non-combustible and have good resistance to chemicals, making them a safe and durable option for insulation in industrial settings. They can effectively trap heat and prevent energy loss, improving the overall efficiency and performance of the machinery. Overall, fiberglass fabrics are a reliable and effective choice for insulation in industrial machinery.

- Q: How does fiberglass fabric perform in fatigue resistance?

- Fiberglass fabric is known for its excellent fatigue resistance. Its strong and durable properties make it highly resistant to cyclic loading and repetitive stress, allowing it to withstand repeated mechanical or thermal stress without significant degradation. This makes fiberglass fabric a preferred choice in applications where fatigue resistance is crucial, such as in aerospace, automotive, and marine industries.

- Q: Does fiberglass fabric have any health hazards?

- When used correctly, fiberglass fabric does not present significant health risks. However, it is crucial to exercise caution and take specific measures to reduce potential dangers when working with fiberglass fabric. The primary issue with fiberglass fabric lies in its ability to emit fine fibers or dust particles into the atmosphere, which can be harmful if inhaled. These fibers can cause irritation to the skin, eyes, and respiratory system, resulting in temporary symptoms like itching, redness, coughing, or breathing difficulties. Prolonged exposure to fiberglass fibers can also lead to more severe health problems, including lung scarring (fibrosis) or cancer. To prevent exposure and minimize health risks, it is advisable to consistently wear personal protective equipment (PPE) while handling fiberglass fabric. This includes donning gloves, long-sleeved clothing, safety glasses, and a dust mask or respirator. Furthermore, working in a well-ventilated area or utilizing local exhaust ventilation systems can effectively decrease the concentration of airborne fibers. It is important to note that fiberglass fabric itself is not toxic, as it consists of bonded glass fibers and resin. The potential health risks arise from the release of these fibers into the air, primarily during activities such as cutting, sanding, or other processes that generate dust. Overall, by adhering to proper safety protocols, fiberglass fabric can be used safely without significant health hazards. Nevertheless, it is imperative to take precautions to minimize exposure to airborne fibers and protect oneself when working with this material.

- Q: Can fiberglass fabric be used for making clothing?

- Clothing production with fiberglass fabric is feasible, although it is not widely adopted in the fashion industry. Fiberglass fabric is renowned for its durability, strength, and ability to resist high temperatures. It finds common usage in insulation, fireproofing, and protective gear within industrial settings. However, its qualities render it an unpopular option for clothing. The stiffness of fiberglass fabric, along with its potential to cause itchiness and discomfort against the skin, discourages its use. Moreover, the fabric lacks breathability, leading to excessive perspiration. Additionally, its inflexibility and poor draping properties make it challenging to create well-fitted and mobile garments. Hence, although technically viable, the fashion industry rarely employs fiberglass fabric for clothing production.

- Q: Is fiberglass fabric resistant to tears and punctures?

- Fiberglass fabric is widely recognized for its exceptional ability to withstand tears and punctures. This can be attributed to the strength and durability of fiberglass, which is derived from delicate glass fibers. These fibers are intricately interwoven to produce a fabric that exhibits remarkable resistance against tearing and puncturing. Moreover, manufacturers often apply specialized coatings or finishes to fiberglass fabric, thus augmenting its tear and puncture resistance. Nevertheless, it is crucial to acknowledge that the precise degree of resistance may fluctuate based on the particular construction and caliber of the fiberglass fabric.

- Q: Can I put up wall tiles on the bathroom wall waterproof cloth?

- With the coil, first clean the base, so that the base drying, and then roll on the ground, with the spray gun heating coil, is between the coil and coil gap bonding. But the material is relatively fragile, the surface is easy to break in when the gravel backfill and the pipeline root and Water Leakage, not very good treatment.

Send your message to us

Fabric for Fiberglass Speaker Box - Fiber Glass Stitched Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords