Fabric Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Fiberglass cloth coated vermiculite is a kind of high-temperature resistant products which fiberglass cloth coated by vermiculite.

Application:

Suitable for insulation for hard and soft pipe;

Thermal insulation cover,refractory shell,other insulation layer for heating machine and freezers;

Reinforcement materials for fiber reinforcement plastics like vessel,vehicle,stock tank,panel,furniture;

Movable thermal insulation cover,fireproof blanket,fireproof curtain,expansion joints and fume ductwork.It can be made into high temperature fireproof cloth and gloves which ca-n be used at high-temperature work like fireproof,stainless steel and industry;

Heat shield curtain,prevent molten liquid,welding blanket.

Product Capability:

Higher temperature resistant,thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

Higer wire resistance;

Nontoxic and harmless to the environment.

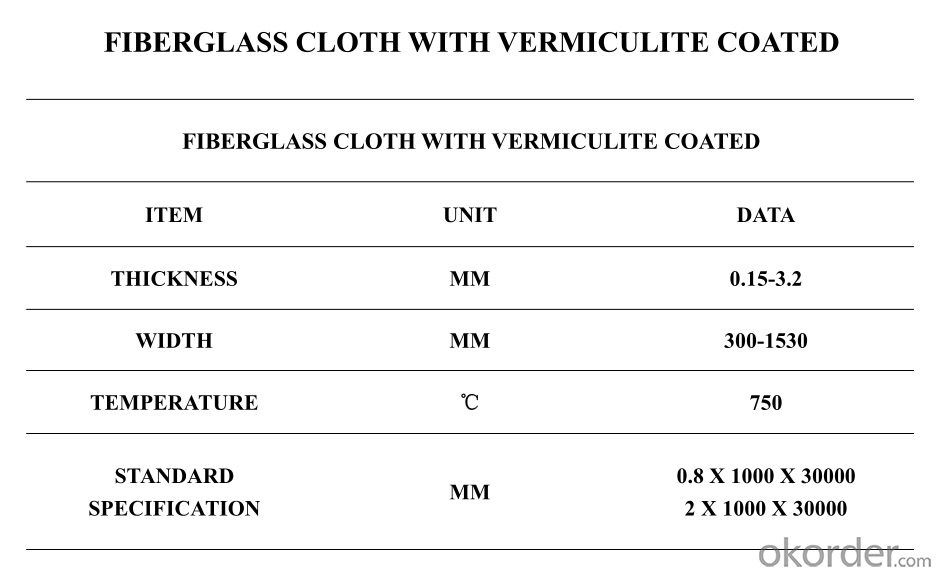

Data Sheet:

:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: Can fiberglass fabrics be used for reinforcement in architectural structures?

- Indeed, architectural structures can benefit from the use of fiberglass fabrics for reinforcement. Fiberglass, known for its strength and lightweight nature, possesses exceptional resistance to corrosion and high tensile strength, rendering it an ideal choice for reinforcing various architectural elements. The construction industry often employs fiberglass to strengthen concrete structures like walls, beams, and columns. By embedding fiberglass fabrics into concrete, its durability and strength increase, offering additional support and minimizing the risk of cracks or structural failure. Moreover, fiberglass fabrics display flexibility, allowing easy molding and shaping to accommodate diverse architectural designs and structures. Ultimately, fiberglass fabrics prove to be a versatile and dependable option for reinforcing architectural structures.

- Q: Can fiberglass fabric be used for insulation panels?

- Yes, fiberglass fabric can be used for insulation panels. It is a common material choice for insulation due to its excellent thermal resistance properties and ability to effectively trap air, which helps in reducing heat transfer. Fiberglass fabric is also lightweight, flexible, and easy to install, making it suitable for insulation applications in various industries.

- Q: Are there any specific installation instructions for fiberglass fabrics?

- Yes, there are specific installation instructions for fiberglass fabrics. It is recommended to thoroughly clean and prepare the surface before applying the fabric. The fabric should be cut slightly larger than the area to be covered, allowing for overlap. It is important to apply a suitable adhesive or resin to both the fabric and the surface, ensuring proper adhesion. The fabric should be smoothed out and any air bubbles or wrinkles should be removed. Additionally, proper curing time should be allowed for the adhesive or resin to set before any further steps are taken.

- Q: Can fiberglass fabric be used for reinforcement in construction materials?

- Yes, fiberglass fabric can be used for reinforcement in construction materials. It is a popular choice due to its high strength-to-weight ratio, durability, and resistance to corrosion. It is commonly used in applications such as reinforcing concrete, strengthening structural elements, and enhancing the overall performance and longevity of construction materials.

- Q: How does fiberglass fabric compare to other fabric materials in terms of cost?

- Fiberglass fabric can vary in cost depending on various factors such as quality, thickness, and specific application. Generally, fiberglass fabric tends to be more expensive than traditional fabrics such as cotton or polyester. However, when compared to specialized industrial fabrics like Kevlar or carbon fiber, fiberglass fabric often offers a more cost-effective solution. Fiberglass fabric's affordability is mainly due to its wide availability and relatively low production costs. Additionally, fiberglass fabric's durability and longevity can contribute to cost savings in the long run, as it may require less frequent replacement or repair compared to other fabric materials. Overall, while fiberglass fabric may not be the cheapest fabric material available, it is often considered a cost-effective choice for various applications.

- Q: Is fiberglass fabric suitable for use in medical applications?

- Yes, fiberglass fabric is suitable for use in certain medical applications. Fiberglass fabric is known for its high strength, durability, and resistance to heat and chemicals, making it a suitable material for various medical applications. It is commonly used in orthopedic casts, splints, and braces, as it provides excellent support and immobilization of injured limbs. Fiberglass fabric is also used in wound dressings and bandages, as it can be impregnated with antimicrobial agents to prevent infections and promote wound healing. Additionally, fiberglass fabric can be used in surgical drapes and gowns, providing a barrier against fluids and contaminants. However, it is important to note that fiberglass fabric may not be suitable for direct contact with open wounds, as it can be abrasive and cause irritation. Therefore, the specific application and intended use should be carefully considered before incorporating fiberglass fabric in medical settings.

- Q: What is the "three proof cloth"? How to correctly use the three proof cloth?

- Three proof cloth is PVC coated glass fiber cloth.

- Q: Can fiberglass fabric be used for making flexible hoses?

- Certainly! Flexible hoses can be made using fiberglass fabric. This material is renowned for its exceptional strength and flexibility, rendering it suitable for a wide range of purposes. Notably, it is commonly employed in the production of flexible hoses due to its unique attributes. By weaving the fabric into a flexible structure, it becomes capable of enduring bending, twisting, and stretching without compromising its integrity. Furthermore, fiberglass fabric exhibits resistance against high temperatures, chemicals, and abrasion. This outstanding feature makes it highly suitable for hoses that transport fluids, gases, and even solids. Given its durability and flexibility, it comes as no surprise that fiberglass fabric is extensively utilized in demanding industries such as automotive, aerospace, and construction, where hoses are constantly exposed to rigorous conditions.

- Q: How does fiberglass fabric perform in terms of moisture absorption?

- Known for its exceptional resistance to moisture absorption, fiberglass fabric does not readily absorb water or moisture due to its non-porous and hydrophobic nature. This characteristic renders it highly suitable for situations where exposure to moisture or humidity is a concern. Moreover, the low moisture absorption of fiberglass fabric aids in preserving its structural integrity and dimensional stability, even in environments with elevated moisture levels. Consequently, fiberglass fabric's outstanding performance in terms of moisture absorption establishes it as a dependable choice across various industries and applications.

- Q: What is the lifespan of fiberglass fabric?

- The lifespan of fiberglass fabric can vary depending on factors such as its quality, usage, and maintenance. However, on average, fiberglass fabric can last anywhere from 10 to 30 years with proper care and handling.

Send your message to us

Fabric Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords