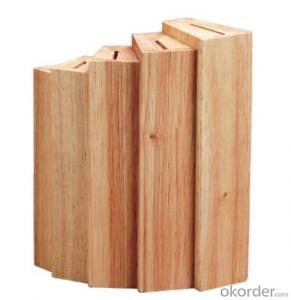

F-KB037 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

N.W.:0.98kg

MEAS:21*15*6.5cm

Description:

1、The knife seat use material of high quality natural rubber wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: CNC lathe turret, sometimes why turn around.

- Open the end of the tool holder, there is a bad disk or water. The solution uses the hair dryer to dry, if it is not OK to replace.

- Q: What are the reasons for the deviation of the CNC lathe tool holder after each turn

- The mechanical structure of the cutter head is damaged, the parts can be replaced, but the new tool holder is recommended. Because the replacement of mechanical parts is also difficult to ensure accuracy, it is best to change the tool holder.

- Q: To the signal line where the pull resistance, pull resistance to do with the trouble to say clearly?

- The pull-up is to position the uncertain signal through a resistor at the high level! Resistive current limiting! Pull empathy!L pull-up is the injection current to the deviceL is weak, but the resistance of the pull-up resistor is differentFor non L (collector or drain) open circuit output circuit (such as the common gate circuit of current and voltage increase) ability is limited, the pull-up resistor is the main function of the open circuit output current output channel for collector

- Q: What is the difference between NC machine tool and tool holder

- In front of the turret with rear turret X axis is not the same, the general system programming does not have what difference, the front turret program got rear turret lathe bed on the same processing, but also have different, like Beijing DTM window system, front and rear arc knife tool that is just the opposite.

- Q: Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- In order to install the taper shank drill, you need to buy or process a tooling, the taper of the inner hole 1:16, the size of the outer circle is determined by the hole of the boring tool holder on your lathe.

- Q: Is the plastic knife holder of roller skate good or metal knife holder good?

- It should not be adapted to the multi slip will be good at the beginning of the selection of a number of domestic imitation shoes cheap and durable more suitable for noviceC3 very heavy... Out of print now if the new shoes about 3000+ old words are not necessarily

- Q: What is the material of the cutting tool

- First say blade. Commonly used materials: 1 high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements. 2: tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than. 3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

- Q: The difference between the turret and the rear turret NC lathe

- The classification processing example scope advantages and disadvantages of different composition of 2.3 ordinary lathe and CNC lathe CNC lathe uses a directory of the two introduction 2.1 CNC lathe 2.2 CNC lathe 2.4 CNC lathe 2.5 CNC lathe CNC lathe CNC lathe 2.6 three 3.1 NC turning process and tooling 3.2 CNC lathe programming 3.3 part four references

- Q: What is the reason why the turret of NC lathe is not maintained?

- May rest inside the lines are wrong, may also have a lid on the knife frame out

- Q: Where are the Holzer elements in the CNC turret?

- Open the cover of the tool holder, and then connect the 6 wire to a good. That's the iron

Send your message to us

F-KB037 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords