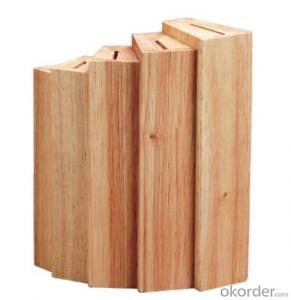

knife seat,F-KB030 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

N.W.:2.86kg

MEAS:26*22.5*16.5cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural rubber wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: How to install CNC machine tool

- Side frame installation(1) remove the strip, the pressure plate, cleaning the guide rail and other processing surface, check the defect and put on the lubricating oil.(2) the connecting piece of the tool holder and the counterweight, such as the bearing, the pulley (or the chain wheel), the axle, the hanging rope or the chain, and so on.(3) the stone school F on the positive exploration in wood, clean school guide surface, with lubricating oil, the side head hanging on it, slowly close to the school with positive guide, strip, plate, preliminary adjustment guide clearance, connection lifting mechanism.(4) connect the counterweight and the side of the turret, rose hand operation knife, check whether there is blocked, demolition of timbers.

- Q: Drilling out of the hole is the overall deviation, the hole is 0.15, the cutting tool angle is not biased, the product is not how to jump, I was the first drilling after the chamfer, is how to go wrong, in this case, ask the teacher, thank you first, urgent...

- Perhaps the clamping part is not strong, you look at whether the clamping, three claws excessive wear.Recommendation: 1 check the three claws.2 hydraulic chuck, increase pressure.3 chamfer first, then hit the center hole.

- Q: How to do the tool holder of the NC turret with too long time

- It is likely to be stuck inside the knife, first give it a break, and then pour some oil inside

- Q: CNC lathe turret in place how to do

- CNC turret repair more complex (personally think), I suggest you find professionals to repair

- Q: Why is the number 980 CNC lathe turret always turn and then alarm

- Tool holder is always unable to find the knife position, usually 24 or 0 volts knife restIf it is a station can not find the detection switch is broken

- Q: Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- In order to install the taper shank drill, you need to buy or process a tooling, the taper of the inner hole 1:16, the size of the outer circle is determined by the hole of the boring tool holder on your lathe.

- Q: The development trend of numerical control tool holder

- Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: The difference between the tool holder and the electric tool holder

- The difference is that there is only one knife library, is T0101, if you want to use a few knives, that is, 02 or more behind the T01 can do it!To row knife knife, if you want to T0101 the knife, you put a knife to a knife or light near the end, directly in the 01 hit patch which according to the Z0 input, the outer circle you have, what is the volume of just the tool compensation which according to the X.. Input, you want to second third or more knife is the same; but you must take the time to fill in to lose in the digital knife to a knife, or otherwise useless.The tool holder is four knife library, you want to use a knife is T0101 or T0202.T0303.T0404. The two is not mixed with the. Hope to help you.

- Q: CNC lathe tool holder clamping bit how to clip

- The drill chuck can be arranged on the knife tower only by processing a drill handle, and a straight shank drill is arranged on the drill chuck.

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- Because, when processing the slender shaft, the process system rigidity problems, mainly for the slender shaft rigidity is low, the cutting force (radial force) under the action of bending deformation (elastic deformation), car axle, a middle drum. The center frame or the tool holder is used to counteract the radial cutting force and increase the rigidity of the slender shaft.

Send your message to us

knife seat,F-KB030 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords