Extruded Aluminum Structural Profiles AA3XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles AA3xxx

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

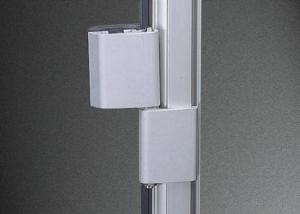

2 Usage/Applications of Aluminum Profiles AA3xxx

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles AA3xxx

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles AA3xxx

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: Are there any fire safety considerations for using aluminum profiles?

- Yes, there are fire safety considerations for using aluminum profiles. While aluminum itself is non-combustible, it can still contribute to the spread and intensity of a fire if not properly protected or used in the right applications. One important consideration is the use of fire-resistant coatings or treatments on aluminum profiles. These coatings can help improve the fire resistance of the profiles, reducing the risk of ignition and slowing down the spread of flames. Fire-resistant coatings can also prevent the release of toxic gases or fumes during a fire, which is crucial for the safety of occupants. Additionally, when using aluminum profiles in structures, it is important to consider their proximity to fire sources or potential ignition points. Proper fire compartmentation and separation measures should be implemented to prevent the rapid spread of fire. This may include using fire-resistant barriers, firestops, or fire-rated walls, depending on the specific application and building codes. Furthermore, the selection of appropriate fire-resistant materials for other components used in conjunction with aluminum profiles is crucial. This includes choosing fire-rated glass, insulation materials, and sealants that can withstand high temperatures and prevent the fire from spreading. Regular maintenance and inspection of aluminum profiles are also important to ensure their fire safety. This includes checking for any damages, corrosion, or wear that could compromise their performance in the event of a fire. Overall, while aluminum profiles can be used safely in various applications, it is essential to consider fire safety measures and ensure compliance with building codes and regulations to minimize the risk of fire incidents. Engaging with fire safety experts or consultants can provide valuable guidance in implementing appropriate fire safety considerations when using aluminum profiles.

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: What are the different powder coating options for aluminum profiles?

- There are several different powder coating options available for aluminum profiles, each offering unique advantages and characteristics. 1. Polyester powder coating: This is the most common and economical option for aluminum profiles. It provides excellent UV resistance and color retention, making it suitable for both indoor and outdoor applications. Polyester powder coatings are available in a wide range of colors and finishes, including matte, glossy, and textured. 2. Epoxy powder coating: Epoxy coatings offer excellent adhesion and corrosion resistance, making them suitable for demanding environments such as marine or industrial applications. They have good chemical resistance and are often used as a primer before applying a topcoat for added durability. 3. Polyurethane powder coating: Polyurethane coatings provide exceptional durability and resistance to abrasion, making them ideal for high-traffic areas or surfaces that are prone to wear and tear. They offer excellent color retention and gloss retention, ensuring a long-lasting finish. 4. Fluoropolymer powder coating: Fluoropolymer coatings, such as PVDF (polyvinylidene fluoride), are known for their outstanding resistance to chemicals, UV radiation, and weathering. They are highly durable and provide excellent color retention, making them suitable for architectural applications where long-term performance is essential. 5. Hybrid powder coating: Hybrid coatings are a combination of epoxy and polyester resins, offering a balance of excellent adhesion and color retention. They provide good weather resistance and are often used in general-purpose applications where cost-effectiveness is a priority. It's important to consider the specific requirements of your project when choosing a powder coating option for aluminum profiles. Factors such as intended use, environmental conditions, and desired aesthetics will help determine the most suitable option for achieving the desired performance and appearance.

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Working with aluminum profiles requires specific safety precautions that should be considered. Here are some important precautions to keep in mind: 1. Personal Protective Equipment (PPE): It is vital to wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to safeguard against potential injuries. Aluminum chips or shavings can cause cuts or abrasions. 2. Ventilation: Ensure that the working area has proper ventilation to prevent the accumulation of aluminum dust or fumes. Aluminum dust can be combustible, and inhaling aluminum fumes can result in respiratory problems. 3. Fire Safety: Due to its high flammability, it is crucial to have fire prevention measures in place. Keep a fire extinguisher nearby and avoid sparks or open flames near aluminum profiles. Choose non-sparking tools and be cautious of excessive heat during cutting or welding processes. 4. Handling and Storage: Aluminum profiles can be heavy, so it is important to use correct lifting techniques to avoid back or muscle injuries. Store aluminum profiles securely and in an organized manner to minimize the risk of tripping or falling. 5. Cutting and Machining: When cutting or machining aluminum profiles, use appropriate tools and techniques. Ensure that the material is securely clamped before any cutting operation to prevent movement and potential accidents. 6. Ergonomics: Prioritize maintaining good ergonomics while working with aluminum profiles to reduce the risk of repetitive strain injuries or musculoskeletal disorders. Utilize ergonomic tools or equipment to minimize strain on the body. 7. Training and Knowledge: It is essential to undergo proper training and acquire knowledge about working with aluminum profiles. Understand the specific properties of aluminum and the associated hazards to work safely and efficiently. By adhering to these safety precautions, the risk of accidents, injuries, or health hazards when working with aluminum profiles can be significantly reduced.

- Q: What are the water-resistant properties of aluminum profiles?

- Because of their natural oxide layer, aluminum profiles have excellent water-resistant properties. This layer acts as a protective barrier, preventing water molecules from penetrating and stopping corrosion. Furthermore, various surface treatments like anodizing, powder coating, or painting can enhance aluminum profiles even more, providing an extra layer of defense against water damage. These treatments not only improve the profiles' appearance but also increase their resistance to water, making them suitable for outdoor use or in areas with high humidity. Additionally, aluminum profiles are inherently structurally sound and dimensionally stable, even in wet environments. This makes them a dependable choice for water-resistant applications such as windows, doors, and façade systems.

- Q: What specific considerations or criteria must be met when using aluminum profiles in the construction of high-rise buildings?

- <p>Yes, there are special requirements for using aluminum profiles in high-rise buildings. These include high strength and load-bearing capacity to withstand the weight and wind forces. Durability is crucial to resist corrosion and weathering over time. Fire resistance is also important for safety. Additionally, aluminum profiles must comply with building codes and regulations specific to high-rise structures. They should also have good thermal insulation properties to maintain energy efficiency and comfort. Lastly, aesthetic considerations are important as the profiles contribute to the building's exterior appearance.</p>

- Q: What are the differences between standard and non - standard shapes?

- Hello, not within the scope of the national standard, so it is called non-standard,The standard piece is within the national standardThat's the difference,This GB standard can be found, are unified

- Q: How do aluminum profiles compare to other types of materials?

- Aluminum profiles have several advantages compared to other types of materials. Firstly, aluminum is known for its lightweight nature, making it easier to handle and transport. This characteristic is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive sectors. Secondly, aluminum profiles offer excellent corrosion resistance. Unlike materials like steel or iron, aluminum does not rust when exposed to moisture or other corrosive elements. This makes aluminum profiles ideal for outdoor applications or in environments where moisture is present, such as marine or coastal areas. Moreover, aluminum profiles have high strength-to-weight ratio, meaning they are relatively strong while being lightweight. This property enables the use of aluminum in various structural applications, where strength is important but weight reduction is also desired. Additionally, aluminum profiles are highly versatile and can be easily extruded into different shapes and sizes to meet specific design requirements. This flexibility allows for customization and adaptability in various industries, including construction, transportation, and industrial manufacturing. Lastly, aluminum is a highly sustainable material. It is 100% recyclable, meaning it can be melted down and reused without any loss in quality. This contributes to reducing environmental impact and promotes a circular economy. Overall, aluminum profiles offer a combination of lightweight, corrosion resistance, strength, versatility, and sustainability, making them a favorable choice over other types of materials in many applications.

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight and durable material that is commonly used in various industries, including playground equipment manufacturing. It is known for its strength and resistance to corrosion, making it suitable for outdoor applications. Aluminum profiles provide structural stability and can withstand the weight and forces exerted during play. Additionally, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the playground equipment. The versatility of aluminum allows for the creation of various shapes and designs, providing endless possibilities for innovative and attractive playground structures. Overall, aluminum profiles are a suitable choice for playground equipment due to their strength, durability, and safety features.

- Q: Can aluminum profiles be used for curtain walls?

- Yes, aluminum profiles can be used for curtain walls. In fact, aluminum is one of the most commonly used materials for curtain wall systems due to its excellent combination of strength, durability, and lightweight nature. Aluminum profiles offer various advantages for curtain walls, including flexibility in design, ease of installation, and low maintenance requirements. Additionally, aluminum is highly resistant to corrosion, which is crucial for exterior applications. The versatility of aluminum profiles allows architects and designers to create aesthetically pleasing curtain wall systems that can withstand environmental factors and provide structural support for buildings.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Extruded Aluminum Structural Profiles AA3XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords