Extruded Aluminum Sheets - Continuous Casting Aluminum Coil AA3003 HO 0.2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Continuous Casting Aluminium Coil is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

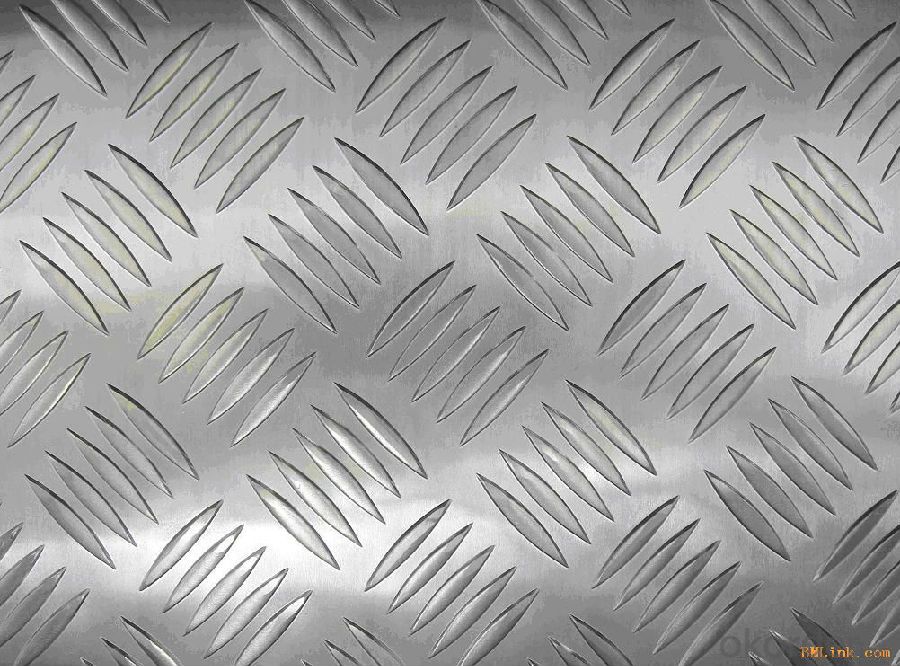

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Aluminum Rated Receptacles

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets varies depending on the alloy and temper. However, a commonly used value is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value represents the stiffness or rigidity of the material, indicating its ability to withstand deformation under applied stress. It is important to note that different grades and conditions of aluminum may have slightly different modulus of elasticity values, so it is recommended to consult the specific material specifications for accurate information.

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: What are the common uses of aluminum sheets?

- Aluminum sheets are highly versatile and widely used in various industries due to their excellent properties. Some common uses of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and insulation purposes. They are lightweight, durable, and corrosion-resistant, making them ideal for creating a protective barrier against the elements. 2. Transportation: Aluminum sheets are extensively used in the automotive and aerospace industries. They are used in the manufacturing of car bodies, truck trailers, and aircraft parts due to their high strength-to-weight ratio. The lightweight nature of aluminum sheets helps improve fuel efficiency and reduce overall vehicle weight. 3. Packaging: Aluminum sheets are commonly used for packaging purposes. They are widely used in the food and beverage industry for making cans, foils, and containers. Aluminum sheets provide an effective barrier against moisture, light, and oxygen, ensuring the freshness and safety of the packaged products. 4. Electrical and Electronics: Aluminum sheets find applications in the electrical and electronics industry due to their excellent conductivity. They are used for manufacturing electrical enclosures, heat sinks, and wiring due to their ability to dissipate heat efficiently and protect sensitive electronic components. 5. Marine Industry: Aluminum sheets are highly valued in the marine industry due to their corrosion-resistant properties. They are used for constructing boat hulls, ship fittings, and other marine equipment. Aluminum sheets' ability to withstand harsh marine environments and their lightweight nature make them an attractive choice. 6. Decorative Applications: Aluminum sheets are commonly used in architectural applications for their aesthetic appeal. They can be easily shaped, formed, and colored to create various decorative elements such as wall cladding, ceilings, and decorative panels. Overall, the common uses of aluminum sheets span numerous industries, including construction, transportation, packaging, electrical and electronics, marine, and decorative applications, highlighting the versatility and importance of this material in various sectors.

- Q: I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- Yes it could be welded with stick but the rod is hard to find (not that good of quality of weld too). Your best bet is to have it tig welded. If you have never welded aluminum then it is probably best to get someone to weld it for you. I would take it apart and take the parts to a weld shop and get an estimate on it. It may be cheaper to try to get the replacement parts from the manufacturer. Or look on eBay for a saw that's the same and try to find one that is damaged you'll get it cheaper. (30 + years welding - certified)

- Q: Is it suitable to use aluminum sheets as roofing materials in areas with high temperatures?

- <p>Yes, aluminum sheets can be used for roofing materials in hot climates. Aluminum has a high thermal conductivity, which means it can quickly dissipate heat, helping to keep buildings cooler. It also has excellent resistance to corrosion, which is beneficial in areas with high humidity or salt air. Additionally, aluminum is lightweight, easy to install, and can be recycled, making it an environmentally friendly option. However, it's important to ensure proper ventilation and insulation to maximize its performance in hot climates.</p>

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: What is the electrical conductivity of 101 aluminum sheets?

- The electrical conductivity of 101 aluminum sheets can be influenced by a range of factors including the individual thickness of each sheet, the level of purity in the aluminum, and the potential presence of impurities or alloying elements. Typically, aluminum is recognized for its relatively superior electrical conductivity when compared to other metals. Nevertheless, without specific details regarding these aforementioned factors, it becomes challenging to provide an exact measurement for the electrical conductivity of 101 aluminum sheets.

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- I'm going to show my calculations anyways Fe2O3(s) + 2 Al(s) -- 2 Fe (l) + Al2O3 (s) From the equation : 1 mole of iron (III) oxide 2 moles of aluminium -- 2 moles of iron 1 mole of aluminium oxide Given that iron = 10.0 g = 10.0 g / 55.8 g per mole = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to iron (III) oxide is 2 : 1 Therefore moles of iron (III) oxide produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (55.8 x 2 + 16.0 x 3) = 14.3 grams (corr to 3 sig fig)' a) 14.3 grams of iron (III) oxide must be used ----- Given that iron = ...... (previously calculated) ...... = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to aluminium is 1 : 1 Therefore moles of aluminium produced = 0.179 mol Convert it back to grams 0.179 x 27.0 = 4.83 grams (corr to 3 sig fig) b) 4.83 grams of aluminium must be used ----- Given that iron = 0.179 mol Because the mole ratio of iron to aluminium oxide is 2 : 1 Therefore moles of Al2O3 produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (27.0 x 2 + 16.0 x 3) = 9.13 grams (corr to 3 sig fig) c) 9.13 grams of aluminium oxide is the maximum mass that could be produced P.S. The relative molecular masses used are from my textbook

Send your message to us

Extruded Aluminum Sheets - Continuous Casting Aluminum Coil AA3003 HO 0.2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords