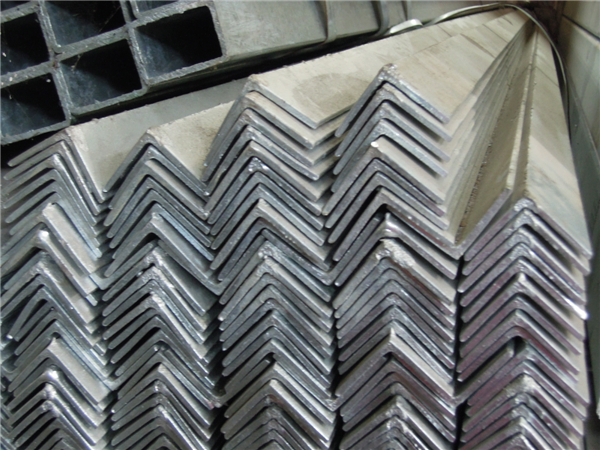

Unequal Leg and Unequal Thickness Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 450000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Name: Angle steel,Steel angle

Type of Angles:Unequal leg and unequal thickness angle steel

Unequal leg and unequal thickness angle steel Main steel grades: S355JR,Q345B,St52-3,S235JR,A283 Grade C,A36,

St372,Q235B,SS400,A,B,AH32,AH36

Steel standard: JIS G3192,GB 9788-88

Main application:Unequal Leg and Unequal Thickness Angle Steels are used to build ship and vessels and other steel structures

Unequal Leg and Unequal Thickness Angle Steel Rolling range: Equal-leg angles 75*75*6mm-250*250*35mm,Unequal-leg angles 100*75*7mm-200*100*16mm,unequal leg and unequal thickness angles 200*90*9*14mm-450*125*11.5*18mm.

Unequal Leg and Unequal Thickness Angle Steel Surface Treatment: Hot rolled and Coated or Shot blasting and painting

Unequal Leg and Unequal Thickness Angle Steel Supply Ability: 50000 Tons per month

Unequal Leg and Unequal Thickness Angle Steel Additional service:Shot blasting and painting,Cutting and welding as per user’s request.

- Q: What are the different types of steel wire products?

- There are various types of steel wire products available in the market, including wire ropes, wire mesh, steel wire rods, steel wire strands, steel wire springs, steel wire nails, steel wire brushes, and steel wire cables.

- Q: What are the applications of alloy steel in the aerospace industry?

- Alloy steel finds various applications in the aerospace industry due to its exceptional strength, durability, and resistance to corrosion and high temperatures. It is extensively used in the manufacturing of aircraft components such as landing gears, engine parts, turbine blades, and structural elements. The high strength-to-weight ratio of alloy steel allows for lighter and more fuel-efficient aircraft designs, while its ability to withstand extreme conditions ensures the safety and reliability of aerospace systems.

- Q: What are the different types of steel tanks and vessels available?

- There are several types of steel tanks and vessels available, including storage tanks, pressure vessels, mixing tanks, fermentation vessels, and process tanks. These tanks and vessels vary in terms of their design, shape, and purpose, but they all utilize steel as the primary material for their construction due to its strength and durability.

- Q: How is steel used in the production of mining equipment?

- Steel is commonly used in the production of mining equipment due to its strength, durability, and resistance to harsh conditions. It is used to manufacture various components such as buckets, shovels, drill bits, and machinery frames, ensuring they can withstand the rigorous demands of the mining industry.

- Q: How is steel used in the production of packaging materials?

- Steel is commonly used in the production of packaging materials due to its strength, durability, and ability to withstand external pressures. Steel is often used to create cans, drums, and other containers that are used for storing and transporting various products. Its resistance to corrosion and impact makes it an ideal choice for packaging materials, ensuring the protection and preservation of goods throughout the supply chain.

- Q: What are the different types of steel coatings and finishes available for steel products?

- There are several types of steel coatings and finishes available for steel products, including galvanized coatings, powder coatings, painted finishes, and stainless steel finishes. Galvanized coatings provide corrosion resistance by applying a layer of zinc to the steel surface. Powder coatings involve electrostatically applying a dry powder onto the steel, which is then cured to form a durable and attractive finish. Painted finishes involve applying liquid paint to the steel, providing both protection and aesthetic appeal. Stainless steel finishes utilize a process of passivation or electropolishing to enhance the steel's natural corrosion resistance and create a smooth, polished surface.

- Q: What are the different types of steel angles and their applications in construction?

- There are several different types of steel angles used in construction, including equal angles, unequal angles, and L-shaped angles. Equal angles have equal sides and are commonly used to provide structural support, such as in the construction of beams, columns, and frames. They are also used in the fabrication of brackets, reinforcements, and various other structural components. Unequal angles have different sides and are often used to provide additional strength or stability in specific applications. They are commonly utilized in situations where unequal loads or forces need to be supported, such as in the construction of staircases, platforms, and supports for conveyor systems. L-shaped angles, also known as angle irons, have a 90-degree angle and are one of the most versatile types of steel angles. They are frequently used in construction for framing, bracing, and supporting various structures. L-shaped angles are often employed in the construction of shelves, frames for doors and windows, and as reinforcement for concrete structures. Overall, steel angles play a crucial role in construction by providing strength, support, and stability to various structures and components. Their versatility allows for a wide range of applications in different construction projects.

- Q: How are steel products used in the food processing industry?

- Steel products are used extensively in the food processing industry due to their durability, corrosion resistance, and ease of cleaning. They are used to manufacture various equipment and machinery, such as storage tanks, conveyors, cutting and slicing tools, and food processing lines. Steel products ensure food safety by preventing contamination and maintaining hygiene standards, making them indispensable in the food processing industry.

- Q: How do steel products contribute to the water and wastewater treatment sector?

- Steel products play a crucial role in the water and wastewater treatment sector due to their durability, strength, and corrosion resistance. They are used extensively in the construction of various infrastructure and equipment, such as pipes, tanks, pumps, and valves, which are essential for transporting, storing, and treating water and wastewater. These steel products ensure the reliability and longevity of the systems, minimizing leaks, failures, and maintenance requirements. Additionally, steel's recyclability and sustainability make it an environmentally friendly choice for the water and wastewater treatment industry.

- Q: What are the different types of steel plates and sheets available?

- There are several types of steel plates and sheets available, including hot rolled steel plates, cold rolled steel plates, galvanized steel plates, stainless steel plates, and alloy steel plates. Each type has its own unique properties and uses in various industries.

Send your message to us

Unequal Leg and Unequal Thickness Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 450000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords