Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

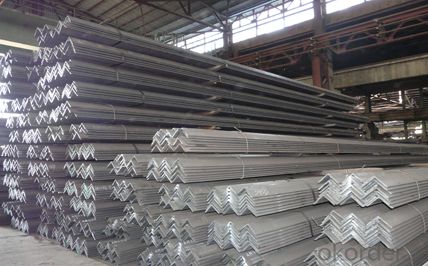

OKorder is offering Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1,Material:Angle Steel

2,Payments:T/T or L/C

3,MOQ:1 Metric Ton

4,Delviery Time: In 30 days

5,Certificate:ISO,BV,LR,MTC.

Material: Q235B/SS 400/A-36 Angle Steel

Standards:ASTM,JIS,GB,EN(DIN,BS,NF) Or Per as clients' requires.

| Material | Q195,Q235,Q345, Grade D,SS400,S235JR,1.0038,304,316,316L,201,202,410,420,ETC |

| Standards | GB/T 13793-1992 ,ASTM,JIS,EN 10025 ETC |

| Origin place | Made In China |

| Delivery Condition | Hot rolled |

| Surface require | Black,Hot Dipped Galvanization,Polish |

| Packing | 1.Seaworthy Packing 2.Wooden Case 3.Carton,Woven Bag Or At Client's Requires |

| Delivery time | In 10-30 days |

| Trade Term | EXW,FOB,CIF |

| Payments | T/T or L/C at sight |

| Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

| MOQ | 1 Ton |

| Product Advantages | 1.Very Fast Delivery Time 2.High Quality And Reasonable Price 3.Sizes Are Enough 4.Many In stocks In warehouse 5.Provide The Sample For Free |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel angles be used for architectural detailing?

- Indeed, architectural detailing can make use of steel angles. These versatile structural elements find application in diverse architectural scenarios. They serve to provide stability and support to structures, fulfilling framing, bracing, and reinforcing purposes. Examples of steel angle implementation can be observed in architectural features like window frames, door frames, staircases, and handrails, among others. Their inherent strength and durability render them fitting for both interior and exterior architectural designs. Furthermore, steel angles can be effortlessly tailored and manufactured to meet precise design specifications, empowering architects to conceive distinctive and visually appealing architectural details.

- Q: Can steel angles be used for structural applications?

- Yes, steel angles can be used for structural applications. They are commonly used in construction and engineering projects to provide structural support, stability, and reinforcement. Steel angles have excellent strength-to-weight ratio, high durability, and versatility, making them suitable for various structural applications such as framing, bracing, trusses, and supports.

- Q: What material is angle iron?

- The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely usedIn a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame, cable bracket, power piping, busbar support installation, and warehouse shelves.Angle steel is a kind of carbon structural steel for construction. It is a simple section steel, mainly used in the frame of metal component and workshop. In use, better weldability, plastic deformation and mechanical strength are required. The raw steel billet for producing angle steel is low carbon square billet, and the finished product angle iron is made by hot rolling, normalizing or hot rolling.

- Q: Can steel angles be used in cold-formed steel construction?

- Certainly, cold-formed steel construction can incorporate steel angles. This construction method entails shaping thin gauge steel sheets into diverse profiles and forms, including angles. Within cold-formed steel construction, steel angles find widespread application in framing systems, support members, and bracing elements, offering structural robustness, stability, and effortless connection or welding with other cold-formed steel components. Moreover, steel angles can be tailored and manufactured to satisfy precise project demands and design specifications in cold-formed steel construction.

- Q: Can steel angles be used as supports for overhead doors or garage doors?

- Yes, steel angles can be used as supports for overhead doors or garage doors. Steel angles are commonly used in construction due to their strength and durability. They provide excellent support and stability for heavy doors, making them an ideal choice for overhead or garage doors. The angles can be securely attached to the walls or framework, providing a solid base for the doors to hang on and operate smoothly. Additionally, steel angles can be customized to fit the specific dimensions and weight requirements of the doors, ensuring proper support and functionality.

- Q: How do you calculate the shear force on a loaded steel angle?

- In order to determine the shear force on a loaded steel angle, one must take into account the applied load, the angle's geometry, and the steel's material properties. The term "shear force" refers to the force that acts parallel to the angle's cross-sectional area. Firstly, it is crucial to ascertain the applied load that is acting upon the steel angle. This load can be either concentrated, distributed, or a combination of both. It is of utmost importance to accurately determine the load's magnitude and location. Subsequently, the steel angle's geometry should be considered. The angle consists of two legs, each possessing specific measurements of length, width, and thickness. Precise measurements of these dimensions are necessary. Once the load and angle dimensions are obtained, the shear force can be calculated by employing the following formula: Shear Force = Load / Cross-sectional Area To calculate the cross-sectional area, one must take into account the angle's shape. Typically, the cross-sectional area of a steel angle is calculated by adding together the areas of both legs and then subtracting the area of the corner radius. In the case of unequal legs, the cross-sectional area can be calculated by adding together the areas of the longer and shorter legs and subtracting the area of the corner radius. After determining the cross-sectional area, divide the applied load by this value to determine the shear force acting on the loaded steel angle. It is important to note that the aforementioned calculation assumes that the steel angle is solely subjected to pure shear. In practical scenarios, additional factors such as bending moments and torsion may need to be taken into consideration, which would necessitate more intricate calculations and analysis. Therefore, it is advisable to consult relevant design codes, principles of structural engineering, or seek the guidance of a professional engineer for accurate and reliable results.

- Q: Are steel angles suitable for coastal or saltwater environments?

- Steel angles can indeed be used in coastal or saltwater environments, but it is essential to consider the steel type and implement proper protection measures for durability and resistance against corrosion. Stainless steel angles, especially those made from marine grade stainless steel like 316 or 316L, are highly regarded for their outstanding resistance to corrosion in saltwater environments. These angles contain higher levels of chromium and molybdenum, which offer superior protection against rust and corrosion caused by exposure to saltwater and other harsh elements. Moreover, additional protective coatings or treatments such as galvanization or epoxy coating can be applied to steel angles to further enhance their resistance to corrosion in coastal or saltwater settings. These coatings establish a barrier between the steel and the corrosive elements, preventing direct contact and reducing the risk of rust or corrosion. To determine the most appropriate steel type and protective measures for a specific project in coastal or saltwater areas, it is crucial to consult with structural engineers, architects, or steel suppliers who specialize in such applications. Regular maintenance and inspections play a vital role in promptly identifying any signs of corrosion or damage and addressing them to ensure the longevity and safety of steel angles in coastal or saltwater environments.

- Q: Are steel angles resistant to impact or vibration?

- Steel angles are generally resistant to both impact and vibration. Steel is known for its strength and toughness, making it highly resistant to impact. It can absorb and distribute the force generated by an impact, preventing structural damage. Additionally, steel angles have a high natural frequency, which means they can withstand vibrations without experiencing significant deformation or failure. However, the resistance of steel angles to impact and vibration may vary depending on the specific grade and thickness of the steel, as well as the intensity and duration of the impact or vibration. It is important to consider the specific requirements and conditions of the application when determining the suitability of steel angles for impact and vibration resistance.

- Q: How do you protect steel angles from corrosion?

- There are several ways to protect steel angles from corrosion. One of the most common methods is by applying a protective coating such as paint or a specialized corrosion-resistant coating. This creates a barrier between the steel and the surrounding environment, preventing moisture and corrosive agents from reaching the metal surface. Another effective method is to galvanize the steel angles. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial anode. The zinc corrodes instead of the steel, providing long-term protection against rust and corrosion. Regular maintenance is also crucial in protecting steel angles from corrosion. This includes cleaning the surface regularly to remove dirt, debris, and other contaminants that can accelerate corrosion. Additionally, inspecting the steel angles for any signs of damage or wear and promptly repairing or replacing any compromised areas can help prevent corrosion from spreading. Using stainless steel angles is another option for corrosion protection. Stainless steel contains a significant amount of chromium, which forms a passive layer on the surface when exposed to oxygen. This passive layer acts as a protective barrier against corrosion, making stainless steel angles highly resistant to rust and corrosion in various environments. Lastly, ensuring proper drainage and ventilation around steel angles is essential to prevent the accumulation of moisture, which can contribute to corrosion. Proper design and installation techniques that minimize contact with water and moisture can significantly extend the lifespan of steel angles and reduce the risk of corrosion.

- Q: Can steel angles be used in industrial or heavy-duty applications?

- Yes, steel angles can definitely be used in industrial or heavy-duty applications. Steel angles are known for their strength, durability, and versatility, making them suitable for a wide range of applications in various industries. They provide structural support, reinforcement, and stability in heavy-duty machinery, equipment, and infrastructure projects. Steel angles are commonly used in construction, manufacturing, engineering, and transportation industries, among others. They can be employed in applications such as frames, supports, bracings, platforms, beams, and trusses, where strength and load-bearing capabilities are crucial. Additionally, steel angles can withstand high temperatures, extreme weather conditions, and heavy loads, making them suitable for challenging industrial environments. Overall, steel angles are a reliable and efficient choice for industrial or heavy-duty applications due to their strength, durability, and adaptability.

Send your message to us

Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords