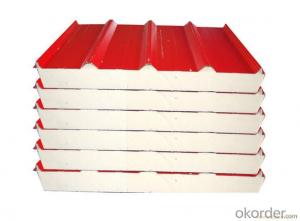

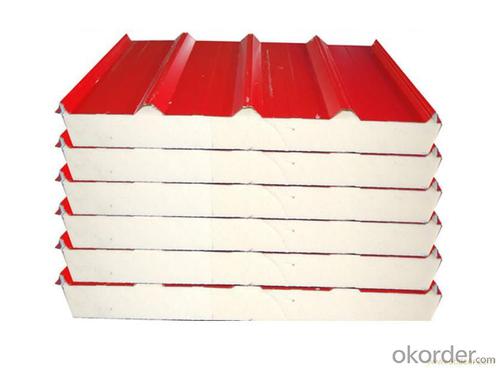

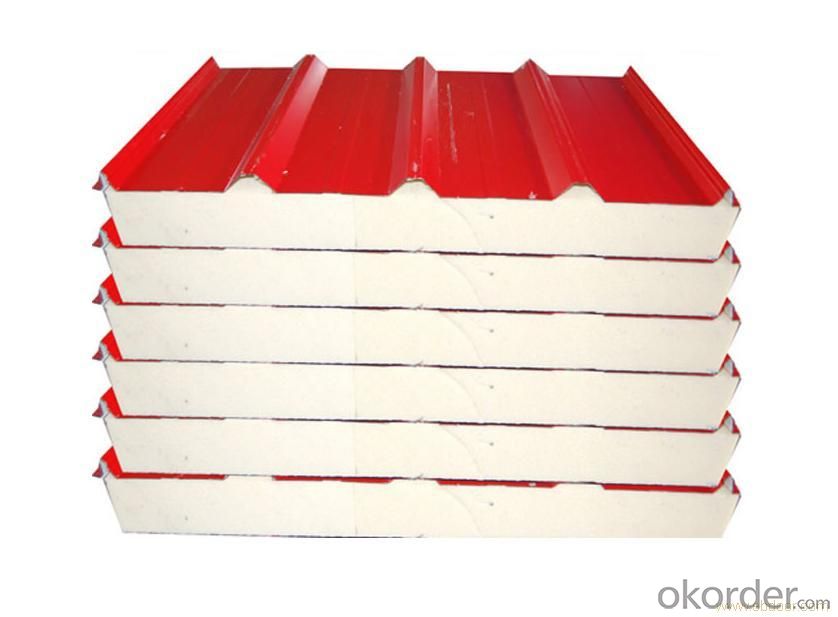

EPS Roof Sandwich Panel/Polystyrene Foam Sandwich Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 25000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

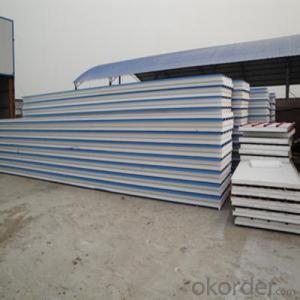

Packaging & Delivery

Packaging Details:covered by LDPE Guard Film and put into the container directly or as required

Delivery Detail:25 working days after receiving 30% deposit

Specifications

1) Sandwich Roof Panel

2) Light Weight,Sound Insulation

3) Heat Insulation,Preservation

4)Fire,Water Proof

5) Fast, Easy

Size

UP/LOWER STEEL SHEET:

Thickness: 0.2mm-0.8mm

Width: 960mm

Material: color-coated panel/zinc plate,hot galvanized plate

Surface: LDPE Guard Film

EPS BEADS:

Density:80kg--120kg/m3

Thickness: 40mm-50mm-75mm-100mm-120mm-150mm-170mm

Length: considering the transportation, it is better don't beyond 11.8 meters.

Rockwool Sandwich Panel Introduce:

Thickness:50mm-150mm

Width:950mm-1150mm

Steel Thickness:0.2mm-0.80mm

rockwool sandwich panel:

Features of rockwool sandwich panel as follows:

- Q: What is the maximum thickness of steel sheets?

- The maximum thickness of steel sheets can vary depending on various factors such as the type of steel, manufacturing process, and application. However, in general, steel sheets can range in thickness from a few millimeters to several centimeters.

- Q: What is the typical elongation of a steel sheet?

- The typical elongation of a steel sheet can vary depending on various factors such as the type of steel, its thickness, and the specific manufacturing process. However, in general, the elongation of a steel sheet is typically around 20% to 40%, meaning it can stretch or deform by that percentage before breaking or rupturing.

- Q: What is the process of galvalume coating on steel sheets?

- The process of galvalume coating on steel sheets involves the application of a zinc-aluminum alloy coating to protect the steel from corrosion. This is typically done through a continuous hot-dip process where the steel sheet is passed through a bath of molten zinc-aluminum alloy. The sheet is then cooled and solidified, resulting in a durable and corrosion-resistant coating on the surface.

- Q: Can steel sheets be used for electrical motors?

- Indeed, electrical motors can utilize steel sheets. Due to its magnetic properties, steel is frequently employed in the construction of these motors. Specifically, the sheets of steel are typically utilized to form the motor's core, which is responsible for generating the essential magnetic field. With its high magnetic permeability, steel can effortlessly conduct and direct magnetic flux, rendering it an optimal material for this purpose. Moreover, steel is durable and capable of withstanding the elevated temperatures and mechanical pressures that electrical motors may encounter while in operation. Consequently, steel sheets are frequently selected as a dependable and economical choice for constructing electrical motors.

- Q: Are steel sheets suitable for decorative applications?

- Indeed, decorative applications can benefit from the suitability of steel sheets. The versatility, durability, and aesthetic appeal of steel sheets allow for their use in a wide range of decorative purposes. They can be easily shaped, sized, and patterned to fit different needs. Steel sheets offer various possibilities for creating decorative elements such as wall panels, room dividers, ceiling tiles, and facades. They can also be utilized for decorative accents like trims, moldings, and decorative screens. The sleek and reflective surface of steel sheets adds a touch of modernity and elegance to any space. Furthermore, steel sheets can be enhanced with different finishes and coatings to further enhance their decorative properties. These options include paints, powder coatings, patinas, and even specialized coatings like faux rust or metallic finishes. With these choices, steel sheets can complement any interior or exterior decor style, opening up a wide range of design possibilities. Additionally, steel sheets are highly durable and long-lasting, making them suitable for both indoor and outdoor decorative applications. They are resistant to corrosion, fire, and extreme weather conditions, ensuring that the decorative elements made from steel sheets maintain their appearance and functionality over time. To sum up, steel sheets are an excellent choice for decorative applications. Their versatility, durability, and aesthetic appeal make them a perfect option for creating visually appealing and long-lasting decorative elements in various settings.

- Q: Are steel sheets resistant to impact and vibration?

- Yes, steel sheets are generally highly resistant to impact and vibration due to their strength and rigidity. The properties of steel make it a durable material that can withstand heavy loads and external forces without significant deformation or damage.

- Q: Are steel sheets suitable for industrial machinery components?

- Yes, steel sheets are commonly used for industrial machinery components due to their high strength, durability, and versatility. They provide excellent structural integrity, resistance to wear and tear, and can withstand heavy loads and extreme conditions commonly found in industrial settings. Additionally, steel sheets can be easily formed, welded, and machined to meet specific requirements, making them a preferred choice for manufacturing various machinery components.

- Q: Can steel sheets be used in the medical industry?

- Yes, steel sheets can be used in the medical industry. Steel is a strong and durable material that can be easily sterilized, making it suitable for various applications in healthcare settings. Steel sheets are commonly used in the construction of medical equipment, such as surgical tables, medical carts, and storage cabinets. They provide stability and support for medical devices and instruments, ensuring quality and safety during medical procedures. Additionally, steel sheets can be used in the fabrication of medical furniture, such as examination tables and hospital beds, due to their strength and resistance to wear and tear. Overall, steel sheets are a reliable and versatile material that can effectively meet the demanding requirements of the medical industry.

- Q: How do steel sheets perform in extreme weather conditions?

- Steel sheets are highly durable and resistant to extreme weather conditions. They are able to withstand high winds, heavy rain, snow, and even hail. Due to their strength and corrosion-resistant properties, steel sheets provide excellent protection against harsh weather elements, making them a reliable choice for various applications in extreme weather conditions.

- Q: What are the different coating options for steel sheets (powder coating, paint, etc.)?

- There are several different coating options available for steel sheets, each offering unique benefits and characteristics. Some of the most common coating options include: 1. Powder coating: Powder coating involves applying a dry powder coating material onto the steel sheet. This coating is then cured under heat to form a protective layer. Powder coating provides excellent durability, corrosion resistance, and aesthetic appeal. It is also environmentally friendly, as it does not contain solvents or VOCs. 2. Paint: Paint is one of the most traditional coating options for steel sheets. It involves applying liquid paint onto the surface, which then dries and forms a protective layer. Paint coatings offer a wide range of colors and finishes, making them suitable for various applications. However, they may require periodic maintenance and can be susceptible to chipping and peeling. 3. Galvanizing: Galvanizing is a popular coating method for steel sheets, especially in industries where corrosion resistance is crucial. It involves applying a layer of zinc onto the steel surface through a hot-dip process. This creates a protective barrier that prevents corrosion and rusting. Galvanized coatings are highly durable and long-lasting. 4. Epoxy coatings: Epoxy coatings are known for their excellent chemical resistance and adhesion properties. They provide a tough and durable finish that protects steel sheets from corrosion, chemicals, and abrasion. Epoxy coatings are commonly used in industrial settings where harsh conditions are prevalent. 5. Chromate conversion coatings: Chromate conversion coatings, also known as chemical conversion coatings, are applied to steel sheets to enhance their corrosion resistance and improve paint adhesion. These coatings are typically thin and translucent, providing a clear or slightly yellowish appearance. Chromate conversion coatings are commonly used as a pre-treatment before painting or powder coating. 6. Ceramic coatings: Ceramic coatings offer exceptional heat resistance and durability. They are often utilized in high-temperature applications, such as exhaust systems or industrial ovens. Ceramic coatings can withstand extreme temperatures, corrosion, and abrasion, making them ideal for demanding environments. These are just a few of the coating options available for steel sheets. The choice of coating will depend on factors such as the intended application, desired appearance, environmental conditions, and budget. Consulting with a coating specialist or manufacturer can help determine the most suitable coating option for specific requirements.

Send your message to us

EPS Roof Sandwich Panel/Polystyrene Foam Sandwich Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 25000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords