Sandwich Panels in High Quality for Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

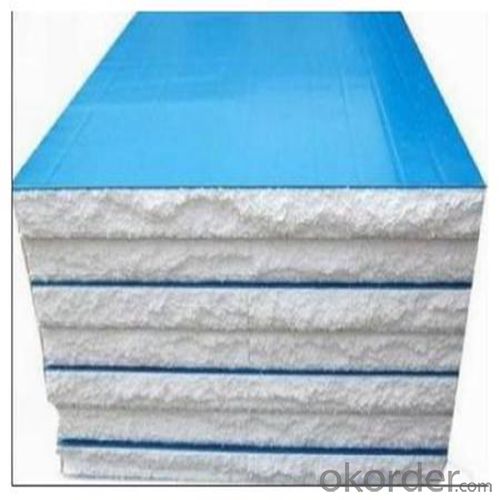

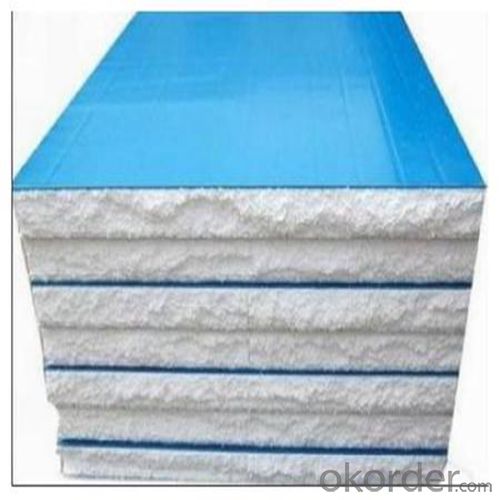

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

1) How to guarantee the quality of the products?

2) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) what policy for broken parts?

4)within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: What are the different surface treatments available for steel sheets to enhance their appearance?

- There are several surface treatments available for steel sheets to enhance their appearance. Some of the commonly used treatments include galvanizing, which involves applying a layer of zinc to protect against corrosion and provide a shiny finish. Another option is powder coating, where a dry powder is electrostatically applied and then cured to create a durable and attractive coating. Additionally, steel sheets can be polished or brushed to achieve a smooth and reflective surface.

- Q: Can steel sheets be used for manufacturing sporting equipment?

- Yes, steel sheets can be used for manufacturing certain types of sporting equipment, such as hockey blades or golf club heads. However, they are not commonly used for manufacturing equipment that requires lightweight and flexible materials, such as tennis rackets or basketballs.

- Q: What are the different surface treatments for galvanized steel sheets?

- There are several surface treatments available for galvanized steel sheets, including chromate conversion coating, painting, powder coating, and zinc phosphate coating. These treatments are used to enhance the corrosion resistance, improve the aesthetic appearance, and provide additional protection to the steel surface.

- Q: What is the average cost of installing steel sheets?

- The cost of installing steel sheets can differ depending on several factors, including project size, steel sheet type and quality, location, and labor expenses. On average, the installation cost varies between $7 and $15 per square foot. Nevertheless, it is crucial to acknowledge that this is merely a general approximation, and actual expenses might differ significantly. It is advisable to obtain quotations from multiple contractors or steel suppliers to acquire a more precise estimate tailored to a specific project.

- Q: Can steel sheets be used for artistic or sculptural projects?

- Absolutely! Steel sheets have endless potential for artistic and sculptural endeavors. This remarkable material boasts incredible flexibility, allowing for a vast array of creative opportunities. Its exceptional strength and durability make it ideal for both indoor and outdoor masterpieces. With steel sheets, you can effortlessly cut, weld, shape, and manipulate them to fashion intricate designs, sculptures, and installations. Artists and sculptors favor steel sheets for their remarkable ability to retain intricate details and withstand diverse weather conditions. Furthermore, steel sheets can be painted, polished, or treated to achieve various textures and finishes, amplifying the artistic allure of the final masterpiece. All in all, steel sheets offer artists a robust and adaptable medium to unleash their creativity and breathe life into their artistic visions.

- Q: Can steel sheets be used for agricultural equipment?

- Yes, steel sheets can be used for agricultural equipment. Steel is a durable and strong material that can withstand the harsh conditions and heavy use associated with agricultural activities. It is commonly used in the construction of farming equipment such as plows, harrows, and seeders. Steel sheets can also be shaped and welded into various forms to meet specific agricultural needs.

- Q: Are steel sheets suitable for oil rig platforms?

- Oil rig platforms benefit greatly from the use of steel sheets. The reason for this lies in the exceptional strength and durability of steel, which makes it a popular choice in their construction. Given the harsh environmental conditions that oil rig platforms face, such as extreme temperatures, high winds, and corrosive saltwater, steel has proven itself capable of withstanding these challenges effectively. Steel sheets offer a solid and dependable base for oil rig platforms. They ensure that the platforms can bear the weight of the rig, equipment, and personnel without compromising stability or safety. The high strength of steel allows for the construction of large and intricate structures without sacrificing stability. Moreover, steel exhibits remarkable resistance to corrosion, making it an ideal material for offshore applications. Oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. However, steel sheets can be treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is a versatile material that lends itself to easy shaping and fabrication. This versatility allows for efficient and cost-effective construction processes, reducing the time and resources required for installation and maintenance. In conclusion, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

- Q: What is the lifespan of a steel sheet?

- The lifespan of a steel sheet can vary depending on several factors such as the quality of the steel, the environment it is exposed to, and the maintenance it receives. However, on average, a properly maintained steel sheet can last anywhere from 20 to 30 years or even longer.

- Q: What are the environmental impacts of steel sheet production?

- The environmental impacts of steel sheet production include carbon emissions, air pollution, water pollution, and the depletion of natural resources. The process of extracting iron ore and refining it into steel requires large amounts of energy, often generated from fossil fuels, leading to significant carbon dioxide emissions. The emissions contribute to climate change and air pollution, impacting human health and the environment. The production process also generates air pollutants such as sulfur dioxide and nitrogen oxides. Additionally, steel production involves the use of chemicals that can contaminate water sources, posing risks to aquatic ecosystems and human consumption. Moreover, the extraction of iron ore and other raw materials for steel production contributes to habitat destruction and the depletion of natural resources.

- Q: Can the steel sheets be easily welded?

- Steel sheets can indeed be welded with ease. Joining steel sheets together is commonly achieved through the process of welding. This procedure entails melting the edges of the steel sheets, followed by allowing them to cool and solidify, resulting in a sturdy connection. It is worth mentioning, however, that the ease of welding may vary depending on factors such as the type and thickness of the steel sheets, as well as the expertise and experience of the welder. Furthermore, it is crucial to adhere to appropriate safety measures and welding techniques to guarantee a successful and secure welding procedure.

Send your message to us

Sandwich Panels in High Quality for Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords