EPDM Waterproof Membrane in 1.5mm with Fleeced Back

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane in 1.5mm with Fleeced Back

Description Of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

We have more than 15 years experience in development & manufacture construction materials such as waterproof membrane,waterproof coils,waterproof panels,waterproof coating,geomembrane,geotextiles etc.Depending on our full set production line,well equipped laboratory,cooperation with institute&college and experienced employees,we have successfully developed and consolidated domestic and foreign market.With a high-tech team of research and development,we have our patent technology, the spray application waterproof membrane.They are the most advanced technology in tunnel and underground projects.Quality is our life,customer satisfaction is our goal, to build the world be more beautiful is our responsibility!

Main Features of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Specifications of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

1. Roofs, Basement, Toilet

2. Industrial and civil building waterproofing

3. Geo-synthetic liner for swimming pool, channels, irrigation system

4. Especially suit for projects with high requirements in durability, anti-corrosion and deformation

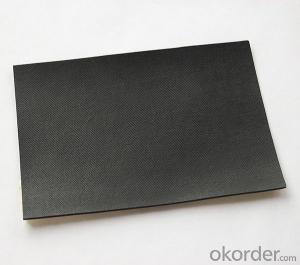

IMages of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

FAQ of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for a swimming pool deck coating?

- Yes, a waterproofing membrane can be used for a swimming pool deck coating. A waterproofing membrane is designed to prevent water penetration and protect the underlying surfaces. When applied correctly, a waterproofing membrane can create an effective barrier against water and moisture, making it an ideal choice for a swimming pool deck coating. It can help prevent water damage, such as cracking, spalling, or deterioration, and also provide a non-slip surface for added safety. Additionally, a waterproofing membrane can help extend the lifespan of the pool deck by protecting it from water-related issues. Overall, using a waterproofing membrane for a swimming pool deck coating is a practical and beneficial choice.

- Q: Can a waterproofing membrane be used for a planter roof?

- Yes, a waterproofing membrane can be used for a planter roof. A waterproofing membrane is designed to prevent water from penetrating through a surface, making it an ideal choice for protecting the roof of a planter. It can effectively prevent water damage to the underlying structure, including potential leaks and deterioration caused by moisture. Additionally, a waterproofing membrane can also help to retain moisture within the planter, ensuring that plants receive adequate hydration.

- Q: Can a waterproofing membrane be applied to existing structures?

- Existing structures can have a waterproofing membrane applied to them. Applying a waterproofing membrane is a commonly used and effective method for preventing water infiltration and damage to buildings. Whether it's a concrete structure, roof, or basement, waterproofing membranes can be installed on the inside or outside surfaces to create a barrier against water penetration. There are various types of waterproofing membranes available, including liquid-applied, sheet, and spray-applied membranes, which can be chosen based on the specific needs of the structure. The process of applying a waterproofing membrane to an existing structure typically involves thorough surface preparation, such as cleaning, repairing any existing cracks or damages, and ensuring a smooth surface. Once the surface is prepared, the membrane is applied using the recommended method to ensure proper adhesion and coverage. Waterproofing membranes are designed to withstand environmental factors like UV rays, temperature changes, and water pressure, providing long-lasting protection for existing structures. However, it's important to consult a professional waterproofing contractor to assess the condition of the structure and determine the most suitable and effective waterproofing solution.

- Q: Do you know how many square meters of waterproofing membrane to send a set of tests?

- Modified asphalt polyethylene tire waterproofing membrane: any volume in the distance 2m at the end of the interception of 1m full-width coil sample 2, 1000 volumes for a group, the lack of a group also

- Q: Does a waterproofing membrane require a protective layer?

- A protective layer is necessary for a waterproofing membrane. It has various functions. Firstly, it prevents damage to the membrane during and after installation by acting as a barrier against sharp objects, construction debris, and potential punctures. Additionally, the protective layer distributes loads evenly and provides stability to the membrane, reducing the risk of damage from foot traffic or heavy equipment. Moreover, the protective layer acts as a shield against UV rays, which can degrade the membrane over time and cause reduced effectiveness and potential leaks. It also helps regulate temperature fluctuations that can stress the membrane and compromise its waterproofing capabilities. To summarize, a protective layer is crucial for the durability and performance of a waterproofing membrane. It safeguards against physical damage, UV radiation, and temperature fluctuations, ensuring the membrane effectively keeps water out and maintains the integrity of the protected structure.

- Q: Can a waterproofing membrane be applied on both interior and exterior surfaces of a structure?

- Both interior and exterior surfaces of a structure can receive the application of a waterproofing membrane. These membranes are designed to form a barrier that prevents water from infiltrating the structure. Regardless of whether it is applied internally or externally, the membrane serves the same purpose of keeping water out and safeguarding the structure against moisture damage. In the case of basements, crawl spaces, or other areas where water intrusion from the inside is a worry, interior waterproofing membranes are typically utilized. On the other hand, exterior waterproofing membranes are commonly used on foundation walls, below-grade areas, or building envelopes to stop water from seeping into the structure. It is crucial to select the appropriate type of waterproofing membrane based on the specific requirements and conditions of the structure.

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are generally resistant to frost damage. Waterproofing membranes are designed to be durable and able to withstand various weather conditions, including freezing temperatures. They are typically made from materials such as modified bitumen, PVC, EPDM, or TPO, which have excellent resistance to frost and other environmental factors. These materials are engineered to remain flexible and elastic even in cold temperatures, ensuring that the waterproofing membrane remains intact and effective in preventing water penetration. Additionally, proper installation techniques and maintenance can further enhance the resistance of waterproofing membranes to frost damage.

- Q: Can waterproofing membranes be used on loading docks?

- Yes, waterproofing membranes can be used on loading docks. Waterproofing membranes are designed to provide a protective barrier against water infiltration, making them suitable for various applications, including loading docks. By installing waterproofing membranes on loading docks, it helps prevent water damage and leakage into the underlying structure, protecting the integrity and durability of the dock. Additionally, waterproofing membranes can also help enhance safety by reducing the risk of slips and falls that can occur due to wet surfaces on loading docks.

- Q: Can a waterproofing membrane be applied to vertical surfaces?

- Vertical surfaces can indeed have a waterproofing membrane applied to them. In reality, waterproofing membranes are frequently utilized on vertical surfaces, like walls, foundations, and retaining walls, for the purpose of safeguarding against water infiltration. These membranes are specifically engineered to stick to vertical surfaces and create a protective barrier against water, thereby thwarting moisture from seeping into the structure. The process of application generally involves cleansing and preparing the surface, applying a primer if necessary, and then affixing the waterproofing membrane using an appropriate adhesive or mechanical fastening system. This guarantees that the membrane forms a continuous and secure seal, effectively preventing water from penetrating. In summary, waterproofing membranes provide an efficient solution for waterproofing vertical surfaces and are extensively employed in construction and building maintenance projects.

- Q: Can a waterproofing membrane be used for roof gardens?

- Indeed, the utilization of a waterproofing membrane is applicable for roof gardens. In truth, it is strongly advised to implement a waterproofing membrane on the roof prior to establishing a garden in order to avert water leakage and harm to the underlying structure. Acting as a shield between the garden and the roof, the waterproofing membrane guarantees that water does not permeate through, thus preventing issues like leaks, mold, or structural destruction. It aids in safeguarding the roof against moisture, root intrusion, and other elements of the environment. Consequently, the inclusion of a waterproofing membrane is imperative for the prosperous and enduring installation of a roof garden.

Send your message to us

EPDM Waterproof Membrane in 1.5mm with Fleeced Back

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords