ENAMELED WIRE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000KGS m

- Supply Capability:

- 30000 MT PER YEAR m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Enameled wire is making for metal wire winding of the electromagnetic coil, by using insulating coatings of insulating points.

Enameled wire is key material for making motor, electronics and home appliances, telecommunications, electronic instrument electromagnetic winding.

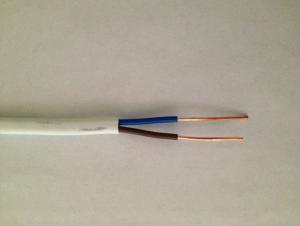

Enamelded copper wire is made of inner conductor and insulation layer.copper wire after annealing and painted repeatedly then baking. We have several kinds of enameled copper wire, such as corona resistance enameled cu wire, polyester enameled cu wire, modified polyester enameled cu wire. QZY enameled CU wire QA cu wire, wich can be weld dirctly, polyester imine composite polyamide imide round enameled copper wire.

This product is edley used for refrigerator compressor, special moter, speical electrical appliances. etc.

- Q: I need to drill a hole in some dry wall and mount an anchor hook to hang a 30+lb fire extinguisher. I am concerned about any electrical wiring or panels behind the dry wall. Any suggestions are appreciated.

- USA You should mount the unit on a stud, not a drywall anchor. That way, you need not worry about wiring. If you do not mount the unit on a stud, you are stupid and deserve the consequences.

- Q: I am running a new 15 amp breaker to 2 new outlets. I wired the first outlet black to brass, white to silver and bare copper to the green screw in the metal box. I then took a new length of wire and connected to my first outlet bottom screws the same way white to silver black to brass an bare copper to the other green screw in the box. then ran the wire to the second outlet and connected it the same way as the other. when i hook up the breaker and restore power the breaker trips. i don't know what i have done wrong Someone please help

- The ground wire should be attached to the actual ground screw on the outlet as well, so you should be coming into box one wired just as you have it with white to silver screw and black to the brass colored screw. The ground should enter the box, wrap around the ground screw in the box, and then attach to the ground screw on the outlet itself. If you are going to the next box, all your connections are the same in there as you mentioned, except the ground needs to be continued into box 2 the same way, from the ground screw in box one ( under the screw in the box) to the screw in box 2, and then to the ground screw on the outlet. My guess is that somewhere in your wiring you have a hot connector too near or touching a ground and that is where your problem is. It could be a staple that is too tight and has pierced the outer casing of the Romex and connects the hot conductor with the ground wire INSIDE the romex outer casing. Check any staples from the box all the way through to box one and then to box two. Use a pair of pliers to loosen all staples a little ( the wire should be able to slightly slide under the casing without catching. I am assuming that in the panel you have hooked the black wire to the breaker screw, the white wire and bare wire to their buss bars inside the panel. One of these will find the short that is causing your breaker to trip.

- Q: I remember places used to sell a box that you would plug into an electrical outlet that you would also plug your cable tv into. Then you would put another box somewhere in your house and it would in essence allow you to add an extra cable jack in the house wherever you wantedI can't remember what this is called. I know it existed because a few times I contemplated buying one. I'm interested in finding one now. If anyone could point me in the right direction, I'd be grateful.

- i'm incredibly particular it somewhat is impossible by using fact the flexibility working in the process the cables would distort the sign. i think of there are some products available that are instant transmitter and receiver. You connect the television sign to the transmitter and it wirelessly get gained on the different end. i will attempt and locate such product and placed up a link right here. sturdy success, Jamie.

- Q: Ready to buy specifications 1.5 square 4 bundles, 2.5 square 4 bundles, 4 square 2 bundles. What kind of color do you want to buy in general? How much does each color buy? Online look at the general use of blue for the zero line, red for the line of fire, yellow and green for the ground, it is not every specification must have three colors? Such as 1.5 square four bundles of color how to allocate it? The problem is relatively white, trouble everyone to answer in detail, thank you! The The More

- Red line on the red line; blue line on the blue line; and yellow line on the yellow line on it

- Q: Several colors of the power line represent how much voltage the voltage is

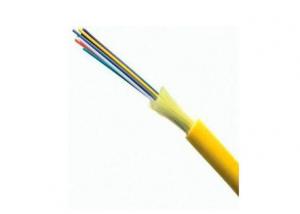

- CD-ROM fiber optic patch panel for a variety of purposes - both for fiber distribution box, can also be used as a cable terminal box; can be individually assembled into an optical fiber patch panel, but also with the digital wiring unit, audio wiring unit A cabinet / frame constitutes an integrated patch panel

- Q: I am replacing an existing electrical short wire (about 3 inches - can't tell what it is) from my circuit panel to my central air breaker box. I am also extending it 15 feet. My air conditioner panel box is rated for 30 amps, but my air conditioner has a max value of 22.6 Amps imprinted on the side. I bought some 12-2 wire, but should I go with the 10 gage instead?

- yes 10 ga is the best 12 will only cary 20 amps safely

- Q: i don't have any more information science class-extra creditt THANKS A MILLION

- Al and Cu.

- Q: I have an unfinished basement with a drywall ceiling. I will be running 12/2 electrical wire about 25 feet across the basement to the breaker box. Can I run the electrical wire on the outside of the drywall and staple it in place? I don't feel like fishing the wire through the ceiling.

- It's not that much work to fish it through. Really, it's not. And then it will be done the right way. Outside the drywall and stapled up isn't legal by me and probably isn't near you either.

- Q: I believe that someone done this to be intentionally, and it did infact catch on fire. The two wire were spliced together and it lay across my heating vent. Mind you the wire laying across the heater never melted it was just off the heater were it caught afire. I was thinking that something was pasted or pored on the wire to make sure that it would catch, something like asatone or a paint product? Here are some of the numbers and letters that were on the wire AWM 2468 VW-1 60 degree 300V AWG24 H.W.G. C. Please and Thankyou Im just looking for answers.

- Yes; okorder

- Q: I have a '49 ford truck, w/350 v8 Chevy engine. The fan is currently hot wired straight to the battery. How do I connect it to the ignition so the fan goes off when I shut off the engine?

- a few options, You could get a 'fuse tap' and clip it into an existing fuse on the load side of fuse- which is the side that the power is fused, it will not have power unless the fuse is in place-(remove fuse then use test lite to verify) Then you can connect your fan power, use a fuse for an option that is either used rarely or not being used or you can wire to the starter solenoid -there is usually a terminal that will test hot only with ignition on. or The older ignition switches have multiple terminals, where you can test and see which one goes on and off with the ignition in run position(it would be best to be sure it does not power up during 'start 'up so you don't lose any cranking power. Another option which may be the best is to leave it wired as is but be sure it is protected by a fuse, and add in a 'thermo switch' You can get these from J C whitney , It is a switch that will wrap or attach around a heater or radiator hose that will turn ON the fan At a certain temperature and off after it gets below that temp. It is a momentary control by temperature. This can also be used if you wire through ignition so it will not be On all the time with the ignition but only when the temperature switch calls for it . if not wired through ignition it would work to cool down the radiator when you shut down too! , But if you select a too low temp. switch it could stay on very long and drain battery. to locate hot wires, use either a multi tester - or a test light with ground clip. i hope this helps

Send your message to us

ENAMELED WIRE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000KGS m

- Supply Capability:

- 30000 MT PER YEAR m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches