Hindalco Aluminum Roofing Sheets - EN AW-5083 Aluminium Panel for Oil Tanker Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW-5083 Aluminium Panel for Making Oil Tanker Description

EN AW-5083 Aluminium Panel for Making Oil Tanker is one semi-finished aluminium material. The alloy AA5083 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW-5083 Aluminium Panel for Making Oil Tanker

EN AW-5083 Aluminium Panel for Making Oil Tanker | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW-5083 Aluminium Panel for Making Oil Tanker

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW-5083 Aluminium Panel for Making Oil Tanker

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW-5083 Aluminium Panel for Making Oil Tanker

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

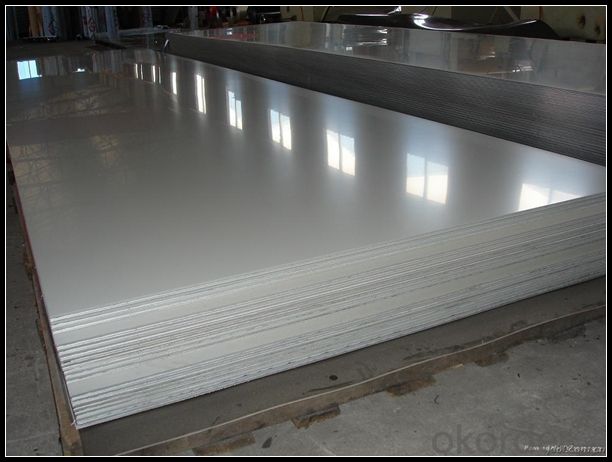

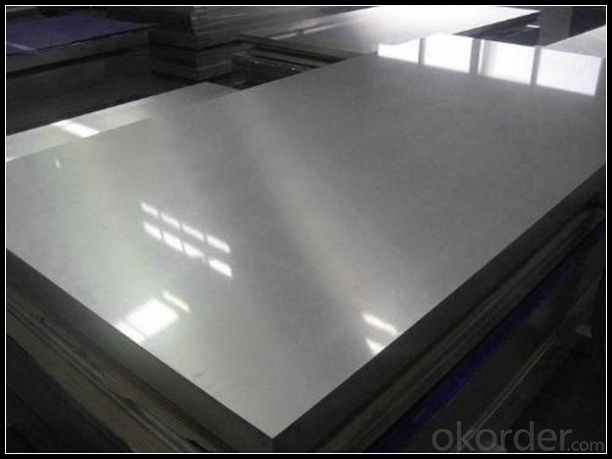

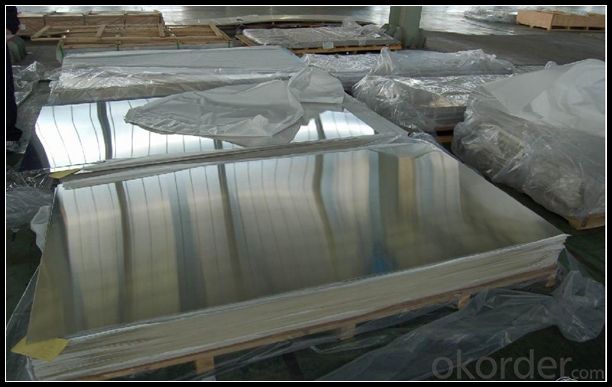

6. Image of EN AW-5083 Aluminium Panel for Making Oil Tanker

7. Package and shipping of EN AW-5083 Aluminium Panel for Making Oil Tanker

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Indeed, aluminum sheets are apt for pharmaceutical packaging. The pharmaceutical industry extensively utilizes aluminum owing to its distinctive attributes. As a lightweight material, it offers exceptional safeguarding against moisture, oxygen, and light. Consequently, it becomes an ideal choice for packaging delicate pharmaceutical products that necessitate superior protection and stability. Additionally, aluminum sheets exhibit remarkable resistance to corrosion and boast commendable heat conductivity, facilitating efficient heat sealing in the packaging procedure. Moreover, aluminum is non-toxic and non-reactive, guaranteeing the safety and soundness of pharmaceutical items. In summary, aluminum sheets emerge as a dependable and frequently employed substance for pharmaceutical packaging.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q: Are aluminum sheets suitable for architectural canopies?

- Yes, aluminum sheets are suitable for architectural canopies. Aluminum is a popular choice for architectural applications due to its lightweight nature, durability, and flexibility. It offers high strength-to-weight ratio, making it capable of withstanding various weather conditions and providing stability for canopies. Additionally, aluminum is highly resistant to corrosion, ensuring that the architectural canopy remains visually appealing and functional for a long time. Its malleability allows for easy fabrication and customization, enabling architects and designers to create unique and intricate canopy designs. Furthermore, aluminum is a sustainable material as it can be recycled, contributing to environmentally friendly construction practices. Overall, aluminum sheets are a reliable and versatile option for architectural canopies.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and every metal has a property that it holds electrons of its outer most orbital quite loosely ( it is electropositive ). And our hand's skin consists of mostly COVALENT bonded compounds which hold their electrons quite tightly. So if we touch aluminum the chances are strong that the electrons are being transferred from aluminum to our hands. But since our hand have covalent compounds so the total transfer must be very small if it is anyway. Otherwise we feel shock every time we touch a neutral aluminum also IF U develop some negative charge then aluminum will take that charge since it has small hold on the outermost electrons. so it easily takes charge frm yr hand at lower potential to its ground potential surface.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum... airplanes are not chrome plated... weight and the difficulty of electro-plating an entire aircraft are the reasons Could likely get some dissimilar metal corrsosion problems as well... Polished aluminum airplanes are absolutely beautiful, but it takes an incredible amount of work to get it that way, and a nearly equal amount of work to keep it up... plan on spending lots of time, money or both...

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Yes, aluminum sheets are suitable for manufacturing audio speaker enclosures. Aluminum is a lightweight and durable material that is commonly used in the production of speaker enclosures. It has excellent acoustic properties, allowing for clear and accurate sound reproduction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the speaker enclosure. Furthermore, aluminum can be easily molded and shaped into various designs, allowing for flexibility in the manufacturing process. Overall, aluminum sheets are a suitable choice for manufacturing audio speaker enclosures due to their acoustic properties, durability, and versatility.

Send your message to us

Hindalco Aluminum Roofing Sheets - EN AW-5083 Aluminium Panel for Oil Tanker Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords