Aluminum Coil 5052 PE/PVDF Painted Aluminum Coil 3003 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PE / PVDF Painted Aluminum Coil 3003 H16

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of PE / PVDF Painted Aluminum Coil 3003 H16

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PE / PVDF Painted Aluminum Coil 3003 H16

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

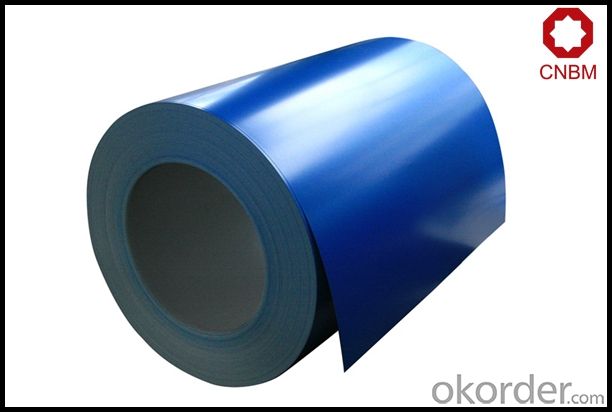

5. Image of PE / PVDF Painted Aluminum Coil 3003 H16

6. Package and shipping of PE / PVDF Painted Aluminum Coil 3003 H16

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in automotive heat exchangers?

- Yes, aluminum coils can be used in automotive heat exchangers. Aluminum is a popular choice for heat exchangers in the automotive industry due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. These properties allow aluminum coils to efficiently transfer heat from one fluid or gas to another, making them ideal for use in automotive heat exchangers. Additionally, aluminum coils are also easy to manufacture and can be formed into various shapes and sizes, further enhancing their suitability for automotive applications.

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in heat exchangers within wastewater treatment plants to transfer heat effectively and efficiently. They are resistant to corrosion and can withstand the harsh environment of wastewater treatment processes.

- Q: Can aluminum coils be used in corrosive gas environments?

- Yes, aluminum coils can be used in corrosive gas environments. Aluminum has a natural oxide layer that provides excellent corrosion resistance, making it suitable for various corrosive environments including those with corrosive gases. However, it is important to consider the specific corrosive gas and its concentration, as certain gases may still have a corrosive effect on aluminum over time.

- Q: What are the potential applications of perforated aluminum coils?

- Perforated aluminum coils offer a wide range of potential applications due to their unique characteristics and versatility. Here are some of the potential uses of perforated aluminum coils: 1. Architectural applications: Perforated aluminum coils can be used in architectural projects for facades, sunscreens, and cladding systems. The perforations can create aesthetically pleasing designs while also providing ventilation and sun control. 2. Filtration systems: The perforated holes in aluminum coils allow them to be used as filters for various applications. They can be utilized in air, liquid, or gas filtration systems, ensuring the removal of contaminants while maintaining an efficient flow. 3. Industrial equipment: Perforated aluminum coils can be incorporated into industrial equipment such as heat exchangers, condensers, and evaporators. The perforations aid in heat transfer, promoting efficient cooling or heating processes. 4. Automotive industry: The lightweight and durable nature of perforated aluminum coils make them suitable for the automotive industry. They can be used in the manufacturing of automobile parts like grilles, radiator covers, and engine components, providing both functionality and aesthetic appeal. 5. Acoustic panels: The perforations in aluminum coils can help in sound absorption and noise reduction. They can be used in the construction of acoustic panels for auditoriums, theaters, recording studios, and other spaces where sound quality is crucial. 6. Decorative applications: Perforated aluminum coils can be utilized for decorative purposes in interior design projects. They can be shaped into screens, room dividers, or wall panels, creating visually appealing patterns and adding a touch of modernity to spaces. 7. Agricultural applications: Perforated aluminum coils can find applications in the agricultural sector. They can be used in crop protection systems, allowing for controlled air circulation while protecting plants from pests or excessive sunlight. 8. Energy-efficient solutions: The perforations in aluminum coils can be beneficial for energy-efficient applications. They can be incorporated into solar panels, allowing light to pass through while maintaining structural integrity. Overall, perforated aluminum coils offer a wide range of potential applications across various industries, including architecture, filtration, industrial equipment, automotive, acoustic panels, decorative projects, agriculture, and energy-efficient solutions. The versatility, lightweight, durability, and aesthetic appeal of these coils make them a popular choice for many different uses.

- Q: How do aluminum coils perform in high-temperature applications?

- Aluminum coils perform well in high-temperature applications due to their excellent heat conductivity and resistance to corrosion. They can efficiently dissipate heat and maintain their structural integrity, making them suitable for various industries such as automotive, aerospace, and HVAC systems.

- Q: Can aluminum coils be used for outdoor applications?

- Yes, aluminum coils can be used for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it a suitable choice for outdoor use. Additionally, aluminum coils are lightweight, durable, and have excellent thermal conductivity, making them ideal for various outdoor applications such as roofing, gutters, and HVAC systems.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: This question asks for the current market price of aluminum coils.

- <p>The price of aluminum coils can vary significantly based on factors such as grade, thickness, width, and market conditions. As of my last update, prices fluctuate daily due to global supply and demand, economic indicators, and geopolitical events. For the most accurate and up-to-date pricing, it's best to consult with metal suppliers or check commodity exchanges like the London Metal Exchange (LME). Prices are typically quoted in dollars per metric ton and can range from a few thousand to several thousand dollars depending on the aforementioned factors.</p>

- Q: What are the different coil packaging materials used for aluminum coils?

- There are several different coil packaging materials commonly used for aluminum coils. These materials are designed to protect the coils during transportation and storage, ensuring they arrive at their destination in good condition. One of the most popular coil packaging materials for aluminum coils is plastic. Plastic packaging can come in the form of shrink wrap, stretch film, or plastic bands. Shrink wrap is often used to tightly encase the coils, providing a secure and protective covering. Stretch film, on the other hand, is used to tightly wrap the coils together, preventing them from shifting and potentially causing damage. Plastic bands are used to secure the coils together, offering an additional layer of stability. Another commonly used packaging material for aluminum coils is paper. Kraft paper or corrugated cardboard is often used to wrap and protect the coils. This type of packaging provides cushioning and prevents the coils from scratching or rubbing against each other during transit. Paper packaging is also easily recyclable, making it an environmentally friendly option. In addition to plastic and paper, steel strapping is sometimes used to package aluminum coils. Steel strapping offers excellent strength and durability, ensuring that the coils remain securely bundled during transportation. This type of packaging material is particularly useful for heavy-duty applications where extra protection is needed. Overall, the choice of coil packaging material for aluminum coils depends on factors such as the size and weight of the coils, transportation requirements, and the level of protection needed. By using the right packaging materials, aluminum coils can be safeguarded against damage and arrive at their destination in optimal condition.

- Q: What are the different coil winding options available for aluminum coils?

- Some of the different coil winding options available for aluminum coils include: 1. Layer winding: This involves winding the aluminum coil in a single layer, where each turn is adjacent to the previous one. This method ensures uniform distribution of the winding and is commonly used for small to medium-sized coils. 2. Pancake winding: In pancake winding, the aluminum coil is wound in a flat, spiral shape. This method is often used for large coils as it allows for efficient use of space and easy handling during transportation. 3. Concentric winding: Concentric winding involves winding the aluminum coil in multiple layers, with each layer placed concentrically around the previous one. This method is suitable for coils that require higher power and voltage ratings. 4. Random winding: Random winding refers to a method where the aluminum coil is wound in a non-uniform or irregular pattern. This technique is typically used for special applications or when the coil needs to fit into a specific space or shape. Overall, the choice of coil winding option depends on factors such as coil size, power requirements, space limitations, and specific application needs.

Send your message to us

Aluminum Coil 5052 PE/PVDF Painted Aluminum Coil 3003 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords