En Aw-5052 Aluminum Coil for Indoor Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 5052 Aluminium Sheet For Indoor Ceiling Description

EN AW - 5052 Aluminium Sheet For Indoor Ceiling is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5052 Aluminium Sheet For Indoor Ceiling

EN AW - 5052 Aluminium Sheet For Indoor Ceiling | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5052 Aluminium Sheet For Indoor Ceiling

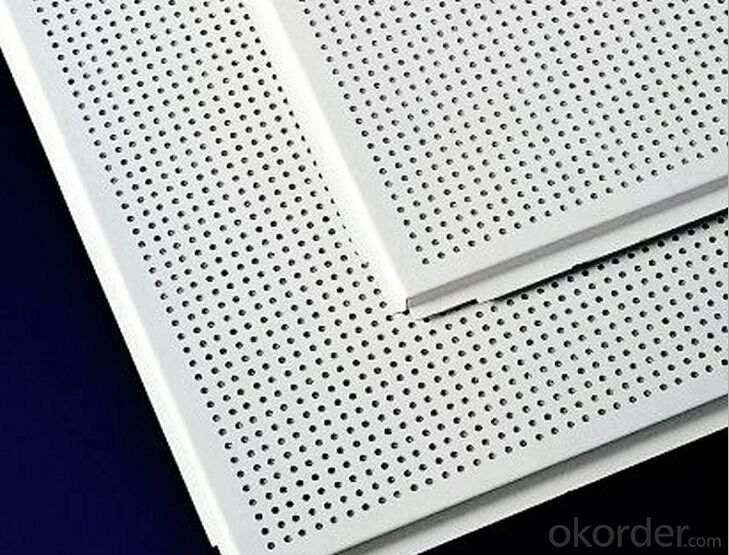

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5052 Aluminium Sheet For Indoor Ceiling

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5052 Aluminium Sheet For Indoor Ceiling

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

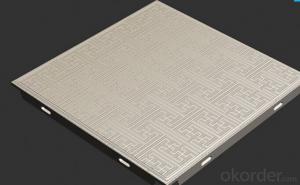

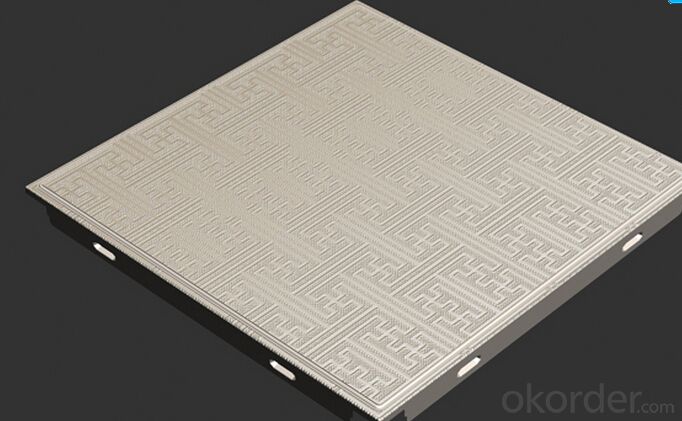

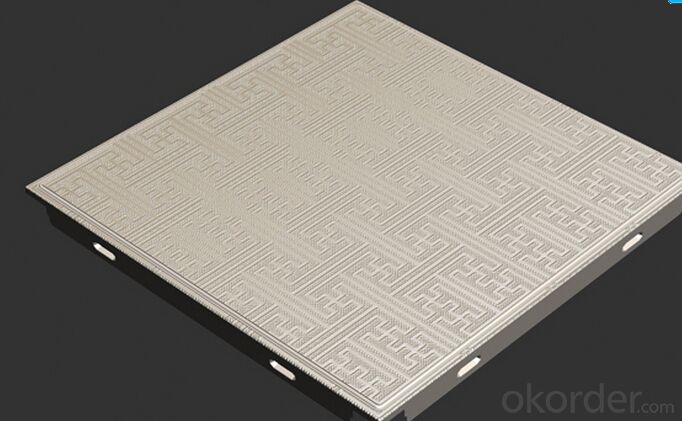

6. Image of EN AW - 5052 Aluminium Sheet For Indoor Ceiling

7. Package and shipping of EN AW - 5052 Aluminium Sheet For Indoor Ceiling

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to use a magnet to determine if an aluminum coil has magnetic properties?

- <p>No, you cannot use a magnet to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not have magnetic properties and will not be attracted to a magnet. Magnets are used to test ferromagnetic materials like iron, nickel, and cobalt. To test for magnetic properties, you would need to use a different method, such as an electromagnetic induction test, which can detect magnetic fields generated by electrical currents in a coil.</p>

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Yes, aluminum coils can be used in the production of heat exchanger fins.

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be modified through various manufacturing processes to meet specific requirements and applications.

- Q: What precautions should be taken to ensure the safe and efficient transportation of aluminum coils?

- <p>The best way to handle aluminum coil during transportation involves using proper lifting equipment, ensuring secure strapping, and maintaining a stable and dry environment. Use slings or lifting beams specifically designed for metal coils to prevent damage. Ensure the coil is strapped tightly to prevent shifting during transit. Keep the coils covered to protect from moisture and dirt. Always follow the manufacturer's guidelines for weight limits and handling procedures.</p>

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- If you go to roller rockers you should do it with the cam and lifters as well as the valve springs so they all match Just adding aluminum heads with roller rockers is like a fish with-out a bicycle! It doesn't make any sense. It all has to match up or you get problems instead of freer movement........and that's what rollers are about ......freeing up the drag caused by friction in the mechanical valve train.

- Q: Can aluminum coils be used for HVAC systems?

- Indeed, HVAC systems can utilize aluminum coils. Aluminum coils are frequently employed in HVAC systems due to their numerous advantages over alternative coil materials. To begin with, aluminum is a lightweight substance, facilitating easier handling and installation. Consequently, this can lead to decreased installation costs and diminished strain on the HVAC system's structure. Furthermore, aluminum coils possess exceptional heat transfer properties. They proficiently transfer heat from the refrigerant to the surrounding air, a critical aspect for the efficient operation of the HVAC system. Additionally, aluminum coils demonstrate a high resistance to corrosion, a quality of particular significance in environments with high humidity or pollutant levels. Moreover, aluminum stands as an immensely recyclable material, rendering it an environmentally conscious choice for HVAC systems. It can be effortlessly recycled and reused, thereby reducing the necessity for extracting new materials and minimizing waste generation. To summarize, aluminum coils represent a reliable and efficient selection for HVAC systems, offering remarkable heat transfer capabilities, durability, and environmental sustainability.

- Q: Is it possible to utilize aluminum coils in the process of water treatment?

- <p>Yes, aluminum coils can be used for water treatment. They are often used in processes such as coagulation and flocculation, where aluminum salts are added to the water to help remove suspended particles and impurities. The aluminum ions react with the particles in the water to form larger, heavier particles that can be more easily settled or filtered out. Additionally, aluminum coils can be part of an electrode system in electrocoagulation processes, where an electric current is used to treat water by generating aluminum ions at the anode. This method is effective for removing various contaminants, including heavy metals, bacteria, and organic compounds.</p>

- Q: What are the potential dangers associated with the use of aluminum coil?

- <p>Aluminum coil, when used in appropriate applications and handled correctly, is generally safe. However, there are some safety risks to consider: exposure to aluminum dust can cause respiratory issues, and improper handling can lead to cuts or burns. Additionally, aluminum can react with certain chemicals, potentially causing hazardous situations. It's important to use personal protective equipment and follow safety guidelines when working with aluminum coil to minimize these risks.</p>

- Q: Can aluminum coils be used for outdoor applications?

- Indeed, outdoor applications can utilize aluminum coils. Aluminum, as a material, possesses outstanding versatility and durability, enabling it to endure diverse weather conditions and temperatures. Its resistance to corrosion renders it suitable for outdoor environments that encounter moisture and humidity. Moreover, aluminum coils boast a lightweight characteristic, facilitating their transportation and installation within outdoor settings. Consequently, they find frequent usage in outdoor applications encompassing roofing, siding, gutters, and HVAC systems. Taken together, the strength, corrosion resistance, and longevity of aluminum coils establish them as a dependable option for outdoor applications.

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications due to their excellent corrosion resistance properties in saltwater environments.

Send your message to us

En Aw-5052 Aluminum Coil for Indoor Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords