5052 Aluminum Coil Manufacture for Exterior Color Coated Aluminum Sheet Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Color Coated Aluminum Sheet Coil for Exterior Description:

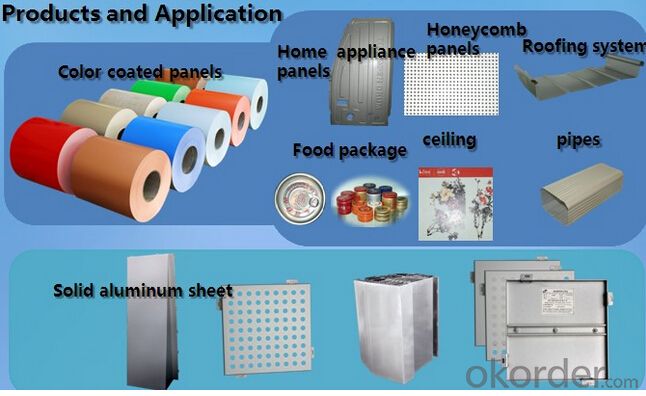

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Color Coated Aluminum Sheet Coil for Exterior :

-----Aluminium sheets coils for curtain wall and ceiling

-----Aluminium sheets or coils for PCB base plate

-----Aluminium sheets or coils for reflector, name plates, advertising board, decorated wall

-----Aluminium sheets coil for ship

-----Aluminium sheets coils for foil

-----Aluminium sheets coils for precoating

-----Aluminium sheets and coils for industrials and other applications

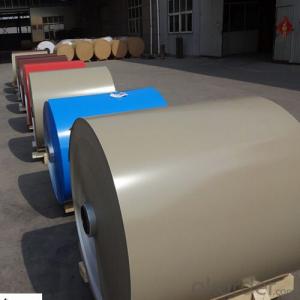

3. Color Coated Aluminum Sheet Coil for Exterior Images:

4. Color Coated Aluminum Sheet Coil for Exterior Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is the creep resistance of aluminum coils?

- The creep resistance of aluminum coils is generally high, as aluminum has a low melting point and exhibits minimal creep deformation under normal operating conditions.

- Q: What are the potential applications of coil-embossed aluminum coils?

- The unique characteristics and properties of coil-embossed aluminum coils make them suitable for a wide range of applications. Here are some examples: 1. In the construction industry, coil-embossed aluminum coils can be used for roofing, wall cladding, and decorative panels. The embossed pattern not only enhances the appearance of buildings but also provides durability due to aluminum's corrosion-resistant properties. 2. In the automotive industry, coil-embossed aluminum coils can be used for manufacturing body panels, trims, and decorative elements. The embossed surface adds texture and style while ensuring resistance to wear and tear. 3. Appliances and electronics can benefit from the embossed patterns on aluminum coils. They can be used for manufacturing refrigerator panels, microwave casings, and other household appliances. The textured surface also improves grip on handheld electronic devices. 4. In the packaging industry, coil-embossed aluminum coils can be used for manufacturing cans, containers, and lids. The embossed surface offers a unique branding opportunity, allowing companies to create visually appealing packaging designs. 5. The signage and advertising industry can utilize the embossed patterns on aluminum coils for manufacturing outdoor signs, billboards, and display panels. The embossed surface adds depth and dimension, making the signage more eye-catching. 6. In the furniture and interior design industry, coil-embossed aluminum coils can be used for manufacturing decorative panels, furniture trims, and accents. The embossed patterns add elegance and uniqueness to furniture and interior spaces. 7. Coil-embossed aluminum coils are also suitable for renewable energy applications. They can be used for manufacturing solar panels and wind turbine components. The embossed surface enhances the efficiency of solar panels by increasing light absorption and reducing reflection. In conclusion, coil-embossed aluminum coils have versatile applications in various industries. The embossed patterns, combined with the inherent properties of aluminum, make them an excellent material choice for both functional and aesthetic purposes.

- Q: What are aluminum coils?

- Aluminum coils, wound in a spiral shape, are thin and flat pieces of aluminum. Their versatility and durability make them commonly utilized in various industries. These coils are typically crafted from high-quality aluminum alloy, which grants them qualities such as lightweight, corrosion resistance, and ease of manipulation. A wide range of applications, including building and construction, automotive manufacturing, electrical appliances, and packaging, benefit from the use of aluminum coils. Depending on the specific requirements of the industry or product, these coils can be further processed into different forms, such as sheets, foils, or strips. Altogether, aluminum coils are crucial components in numerous manufacturing processes and play an essential role in diverse industries.

- Q: Can aluminum coils be utilized to create jewelry boxes and other decorative objects?

- <p>Yes, aluminum coils can be used to make jewelry boxes and other decorative items. Aluminum is lightweight, durable, and has a shiny finish that can add a touch of elegance to decorative pieces. It can be easily shaped and manipulated using various tools and techniques, such as bending, cutting, and engraving. Additionally, aluminum's resistance to corrosion makes it a practical choice for long-lasting decorative items. However, it's important to consider that working with aluminum may require specific skills and tools, and the final appearance can be influenced by the quality of the aluminum and the craftsmanship involved.</p>

- Q: This question asks for the method to cut an aluminum coil into smaller sections.

- <p>To cut an aluminum coil into smaller pieces, you can use a metal cutting band saw, which is designed for cutting metal materials. Ensure the blade is sharp and the speed is appropriate for aluminum. Secure the coil in a vice or a cutting table to prevent movement during cutting. Wear safety goggles and gloves. Turn on the saw and slowly feed the coil through the blade, applying steady pressure. After cutting, smooth any rough edges with a file or sandpaper. Always follow safety precautions and manufacturer's instructions for your specific cutting tool.</p>

- Q: Can aluminum coils be used in the production of chemical storage tanks?

- Yes, aluminum coils can be used in the production of chemical storage tanks. Aluminum is a durable and corrosion-resistant material, making it suitable for containing various chemicals. Additionally, its lightweight nature allows for easier handling and installation of the storage tanks.

- Q: Are aluminum coils compatible with other materials?

- Indeed, other materials can be used in tandem with aluminum coils. Aluminum, being a versatile and extensively utilized substance, readily blends with various materials for different purposes. Take, for instance, the utilization of aluminum coils alongside copper tubing in air conditioning and refrigeration systems to amplify heat transfer efficiency. Furthermore, aluminum coils can be coated or layered with polymers or paints to furnish supplementary safeguard against corrosion, enhance visual appeal, or elevate specific performance attributes. Consequently, aluminum coils exhibit compatibility with a multitude of materials, rendering them apt for an array of applications within industries like construction, automotive, aerospace, and beyond.

- Q: What are the various surface finishes available for aluminum coils?

- Aluminum coils offer a variety of surface finishes to meet different needs and preferences. The options include: 1. Mill Finish: This is the most basic and natural finish achieved by passing the coil through rollers during manufacturing. It gives the aluminum a smooth, shiny appearance. 2. Anodized Finish: Anodizing is an electrochemical process that adds a protective layer to the aluminum coil's surface. It comes in various colors and provides enhanced resistance to corrosion, abrasion, and wear. Architects commonly use anodized finishes. 3. Painted Finish: Aesthetic appeal and environmental protection can be achieved by coating aluminum coils with paint. The paint comes in different colors and finishes, such as matte, glossy, or metallic. 4. Brushed Finish: By brushing the surface with abrasive materials, aluminum coils can have a textured appearance with fine lines or scratches. Brushed finishes are often used for decorative purposes. 5. Polished Finish: Buffing the surface of the aluminum coil creates a smooth, reflective finish. It gives a mirror-like appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: Embossing involves stamping or pressing a pattern or design onto the surface of the aluminum coil. This finish adds texture and depth, making it suitable for non-slip surfaces or decorative purposes. 7. Laminated Finish: Lamination involves bonding a thin layer of film or foil to the aluminum coil's surface. This finish provides additional protection against scratches, stains, or UV radiation. It is commonly used for applications that require durability and resistance. These examples highlight the range of surface finishes available for aluminum coils. The choice of finish depends on specific application requirements, desired appearance, and functional properties needed for the end product.

- Q: What are the different coil slitting methods for aluminum coils?

- There are various coil slitting methods employed for aluminum coils, each with its own advantages and suitability for different applications. Some of the common coil slitting methods for aluminum coils include: 1. Rotary Shear Slitting: This method involves the use of a rotating knife or shear blade to cut the aluminum coil into narrow strips. Rotary shear slitting is suitable for high-speed production lines and offers excellent accuracy and clean edges. 2. Looping Slit: In this method, the aluminum coil is looped and fed through a set of rotating circular blades. The blades cut the coil into desired widths, ensuring precise cuts. Looping slit is commonly used for thin aluminum coils and offers good accuracy and productivity. 3. Double Knife Slitting: Also known as duplex slitting, this method involves the use of two circular knives positioned on top and bottom of the aluminum coil. The knives move in opposite directions, cutting the coil into multiple strips simultaneously. Double knife slitting is suitable for high-volume production and provides excellent accuracy and efficiency. 4. Razor Slitting: This method utilizes razor-sharp blades mounted on a rotating shaft to cut the aluminum coil. Razor slitting is particularly suitable for thinner gauge coils and provides clean, burr-free edges. 5. Crush Slitting: Crush slitting involves compressing the aluminum coil between two rotating rolls with sharp edges. The pressure exerted by the rolls cuts the coil into desired widths. Crush slitting is commonly used for thicker gauge coils and offers good productivity and edge quality. 6. Laser Slitting: Laser slitting employs a high-powered laser beam to cut the aluminum coil. This method offers exceptional precision and accuracy, making it ideal for intricate and complex cutting requirements. The choice of coil slitting method depends on various factors such as coil thickness, desired strip widths, production volume, and edge quality requirements. Each method has its own advantages and limitations, so it is essential to evaluate these factors to select the most appropriate coil slitting method for a specific application.

- Q: Why does the end face of aluminum coil have grease spots?

- The reason may be that the manufacturer hasn’t cleaned. Before being coated, the aluminum should be cleaned carefully. Otherwise the paint will peel off.

Send your message to us

5052 Aluminum Coil Manufacture for Exterior Color Coated Aluminum Sheet Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords