Quick Details

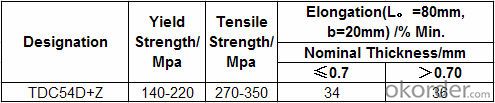

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D,S250GD

Thickness: 0.13-1.2mm

Brand Name: CJC STEEL

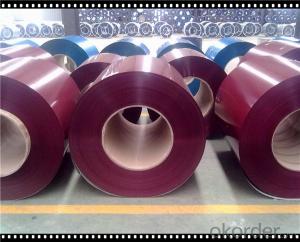

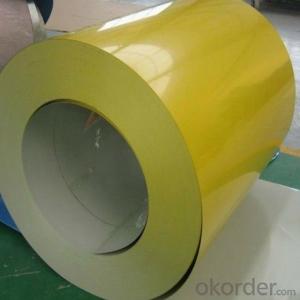

Type: Steel Coil, Diamond Embossed Or As Samples

Technique: Cold Rolled

Surface Treatment: Coated

Application: Building,Roofing

Width: 600-1250mm

Length: As Required

Top Paining: 10-20mic

Back Painting: 5-10mic

Zinc Coating: 50-275GSM

Color: RAL Standard

Coil Weight: 3-10tons

Price: Competitive between 0.13-0.70mm

Quality: Best Quality In Shandong

Service: Immediately&Professional

Packaging & Delivery

Packaging Details: Export Standard Packing Delivery Detail: Within 30days in China After Confirmed the Deposit Or L/C Specifications

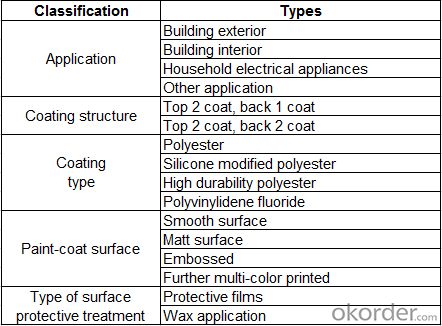

Embossed Prepainted Galvanized Stee Coil

1) Grade:CGCC/CGCD

2) Zinc Coating:50-275GSM

3) Thickness: 0.13-0.70mm

4)CW:3-10ton