Quick Details

Standard: ASTM

Grade: FS Types A

Packaging & Delivery

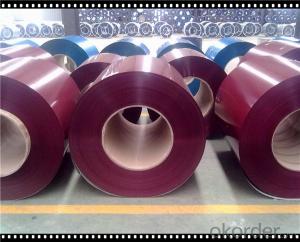

Packaging Details: Oscillated wound: one coil per bundle, inner is the protecting humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) Delivery Detail: 25 days but also depends on the quantity and specifications. Specifications

1. Top 2 coat: primer 5uM, top coat 15-20uM.

2. Back 2 coat: primer 2-5uM, back coat 5-20uM.

3. Back 1 coat: back coat 5-10uM.Type: Steel Coil

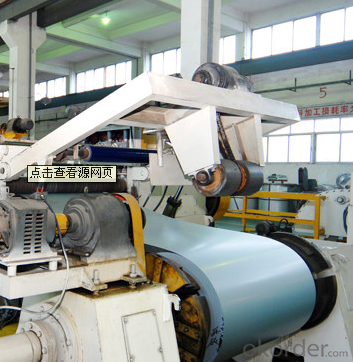

Technique: Cold Rolled

Surface Treatment: Coated

Application: Forming Use

Width: 750-1534mm

Length: Coil

(1) Top 2 coat, back 1 or 2 coat

(2) RAL international color, With/Without temporary protective film(3) Coil ID: 508/610mm, Coil weight: 3-8Ton

(4) Steel Substrate Grade FS(A): Forming steel

Feature

Product | Prepainted galvanized steel coils /PPGI/ color coated steel coil |

Standard | ASTM,GB,JIS |

Base material | Hot dipped galvanized steel |

Thickness | 0.14-2.0mm |

Width | 800-1500mm(according to your need) |

Coil Weight | 3-6tons |

Color | RAL No. or customers samples’ color |

Zinc-coating | 60g/m2-220g/m2 |

Coil DI | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm Back painting: 6~10μm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Packing | Standard export packing |

The special order can be negotiated.

| |