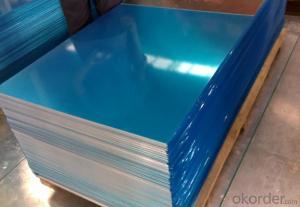

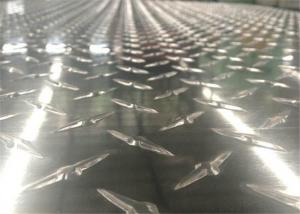

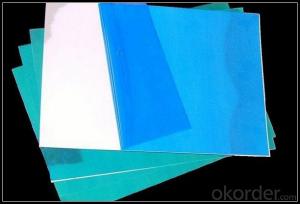

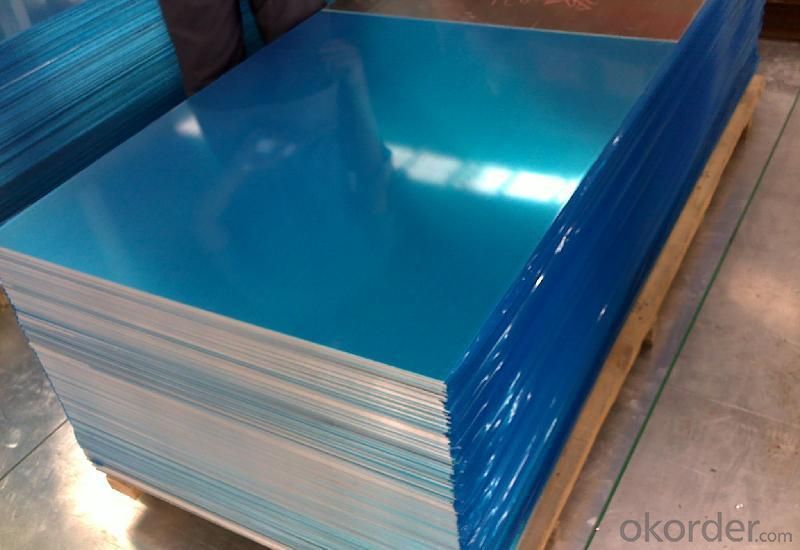

Embossed and Plain Aluminum Sheets 8x10 - Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

embossed aluminum sheet and coil

1.Alloy:1,3,5,8xxx

2.Thickness:0.3-150mm

3.Width:300-1950mm

aluminum foil | | ||||

Products | Alloy | Temper | Gauge range | Width range | |

Household Foil | 8011 | O | 0.009-0.025mm | 150- 1450mm | |

Container Foil | 8011/3003 | H22/H24/O | 0.03-0.22mm | 150-1450mm | |

Flexible Packaging Foil | 8011/1235 | H22/H24/O | 0.006-0.05mm | 150-1450mm | |

Coated Finstock | 8011/1030B | H14/H22/H24/H26/O | 0.095-0.18mm | 200-1450mm | |

Bare Finstock | 8011/1030B | H14/H22/H24/H26/O | 0.095-0.18mm | 200-1450mm | |

Beer wrap Foil | 8011 | O | 0.01-0.015mm | 200-1450mm | |

Lidding Foil | 8011/8079 | O | 0.03-0.05mm | 200-1450mm | |

Pharma(PTP) | 8011 | H18 | 0.015-0.025mm | 200-1450mm | |

Pharma(SP) | 8011 | O | 0.03-0.09mm | 200-1450mm | |

Heat Exchange Brazing Strip | 3003+4xxx | H14/O | 0.08-0.60mm | 16-1100mm | |

Cable wrap foil | 8011/1145 | O | 0,15-0.20mm | 300-1450 | |

Packing: | well packed suitable for long distance sea transportation. | ||||

Application:Mainly used in food packing, electric capacitor, air-conditioner, cable foil, household foil, food container foil, soft packing foil, refrigerator, medicine and so on.

| |||||

Inner diameter: 75mm, 50mm, 200mm, 220mm, 300mm, 405mm or as your request | |||||

Outer diameter: 100-1500mm | |||||

MOQ: | 5MT per size | ||||

Kind attention:can be customized according the customers request. | |||||

Packaging & Delivery

| Packaging Details: | Wooden pallet packing suitable for export. |

| Delivery Detail: | 20 days after paymnet. |

- Q: Can aluminum sheets be anodized for corrosion protection?

- Yes, aluminum sheets can be anodized for corrosion protection. Anodizing is an electrochemical process that forms a durable oxide layer on the surface of aluminum, enhancing its corrosion resistance and providing a protective coating.

- Q: How do aluminum sheets perform in terms of weldability?

- The weldability of aluminum sheets is generally good because of their low melting point and excellent thermal conductivity. Various techniques, such as TIG welding, MIG welding, or spot welding, can be used to weld aluminum sheets. However, there are a few factors that can affect the weldability of aluminum sheets. First, it is necessary to ensure that the surface of the aluminum sheet is clean and free from contaminants like oil, grease, or oxide layers. These contaminants can have a negative impact on the weld quality. Therefore, it is crucial to clean and prepare the surfaces to be welded properly. Second, aluminum sheets have a high thermal conductivity, which means that heat dissipates quickly. This can make it difficult to control the temperature during the welding process. To ensure a successful weld, it is important to have a skilled and experienced welder who can adjust the welding parameters accordingly. Lastly, aluminum sheets have a high coefficient of thermal expansion, which can result in distortion or warping during welding. To minimize these issues, techniques such as tack welding or clamping may be used to hold the sheets in position. In conclusion, aluminum sheets generally have good weldability due to their low melting point and excellent thermal conductivity. However, achieving high-quality welds and avoiding potential issues like contamination, distortion, or warping requires proper surface preparation, skilled welding techniques, and careful temperature control.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- www.okorder /.. its doesnt burn burn u knw.it just becomes sorta britte.it becomes oxidised...u can got more infro there.try..i read it just now

- Q: This question asks for a comparison between aluminum sheets that have undergone anodizing treatment and those that have not, highlighting their distinct characteristics.

- <p>Anodized aluminum sheets are aluminum that has been treated with an electrochemical process to increase its thickness and durability, forming a protective oxide layer on the surface. This process enhances corrosion resistance, wear resistance, and allows for a wide range of colors. Non-anodized aluminum sheets, on the other hand, have not undergone this treatment and are more prone to corrosion and less durable. They also have a more limited color range and are generally softer and less resistant to wear.</p>

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is lightweight, strong, and has excellent corrosion resistance, making it an ideal material for various automotive components such as body panels, hoods, doors, and engine parts.

- Q: Are aluminum sheets suitable for architectural louvers?

- Indeed, aluminum sheets prove to be a fitting option for architectural louvers. The advantageous properties of aluminum make it a favored material for louvers in the field of architecture. To begin with, aluminum possesses the desirable combination of being lightweight and yet sturdy, which makes it an ideal material for architectural louvers. It has the ability to withstand external forces such as wind and various weather conditions while maintaining its structural integrity. This becomes crucial for louvers as they are required to provide ventilation and airflow, all the while retaining their form and functionality. Furthermore, aluminum displays a high level of resistance against corrosion and rust. Considering that louvers are frequently exposed to outdoor elements like rain, moisture, and sunlight, the corrosion resistance of aluminum ensures the longevity and durability of the louvers, even in harsh environmental conditions. In addition, aluminum is an adaptable material that can be easily customized and fabricated into different shapes and sizes. This flexibility allows architects and designers to fashion louvers with unique designs and configurations that suit the specific requirements of the building. Aluminum louvers can be personalized to optimize airflow, control light, and enhance aesthetic appeal. Moreover, aluminum stands out as a sustainable and environmentally friendly material. It is widely recyclable, which means that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Opting for aluminum in the construction of architectural louvers aligns with sustainable building practices and contributes to the overall reduction of environmental impact. In conclusion, aluminum sheets are indeed a suitable choice for architectural louvers. Their lightweight yet robust nature, resistance to corrosion, ability to be customized, and sustainability make them an excellent option in terms of functionality, durability, and aesthetics.

- Q: What are the different alloys used in aluminum sheets?

- Some of the different alloys used in aluminum sheets include 1100, 3003, 5052, and 6061.

- Q: What are the benefits of using aluminum sheets?

- There are several benefits of using aluminum sheets in various applications. Firstly, aluminum sheets are lightweight, making them easy to handle and transport. This characteristic is particularly advantageous in industries such as aerospace, automotive, and construction, where weight reduction is crucial for fuel efficiency and overall performance. Secondly, aluminum sheets offer excellent corrosion resistance. Unlike other metals, aluminum naturally forms a protective oxide layer when exposed to air, preventing further corrosion and enhancing its durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another benefit of using aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight but sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can be easily formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to the production of primary aluminum, resulting in reduced carbon emissions and a reduced environmental impact. Lastly, aluminum sheets have excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. Overall, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

- Q: Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport furniture. Secondly, aluminum is resistant to corrosion, ensuring the durability and longevity of furniture products. Additionally, aluminum sheets can be easily molded and shaped into various designs, allowing for creative and unique furniture pieces. Lastly, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for the furniture industry.

Send your message to us

Embossed and Plain Aluminum Sheets 8x10 - Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords