Elbow Reducer DN150-125 R250-90 Flange148MM-127MM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1.Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2.The experiment done abroad shows that the life of our concrete pump elbow can reach 35000-150000cbm,got the customers' praise.

3.Possess quality certification of ISO 9001:2000. Can pass CE test.

4.We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

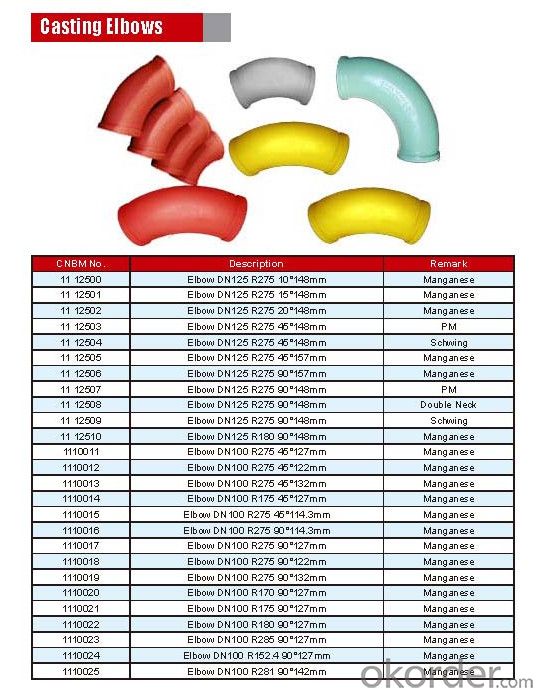

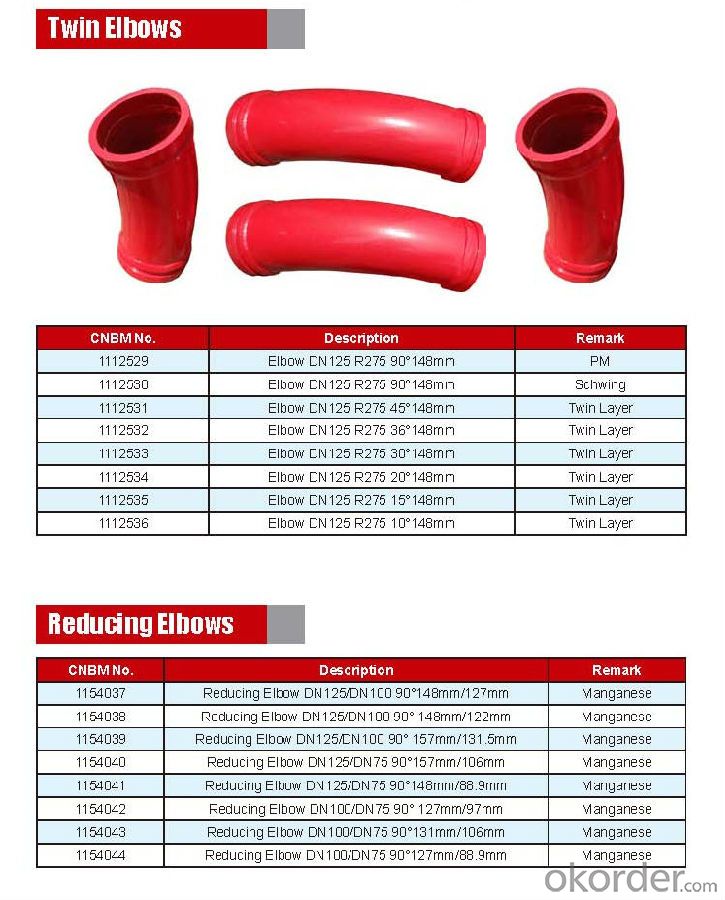

Product Specifications:

Technology: Cast

Dimension: 5″/4″

Flange: 148-127mm

Radius: 250mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for more than ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What are the advantages of using pre-assembled spare parts for concrete pumps?

- There are several advantages of using pre-assembled spare parts for concrete pumps. Firstly, they save time and effort as they come ready to use, eliminating the need for manual assembly. This allows for quicker repairs and reduces downtime for the concrete pump. Additionally, pre-assembled spare parts ensure compatibility and proper fit, reducing the risk of errors or mismatches during installation. They are also manufactured to meet specific quality standards, ensuring reliability and durability. Furthermore, using pre-assembled spare parts eliminates the need for specialized skills or knowledge for assembly, making it convenient for operators and reducing the chances of mistakes. Overall, pre-assembled spare parts offer efficiency, convenience, and reliability in maintaining and repairing concrete pumps.

- Q: Are there any cost-effective alternatives to original concrete pump spare parts?

- Yes, there are cost-effective alternatives to original concrete pump spare parts available in the market. These alternatives, often referred to as aftermarket parts, are manufactured by third-party companies and offer similar quality and functionality as the original parts but at a lower price. However, it is crucial to ensure that the aftermarket parts are compatible with the specific make and model of the concrete pump to ensure proper fit and performance.

- Q: What are the indicators of a faulty concrete pump seal?

- There are multiple signs that may suggest a defective concrete pump seal. These signs include: 1. Leakage: One of the most evident indications of a faulty seal is when concrete or water leaks around the seal area. If you observe any fluid seeping out from the seal, it is a clear sign of a problem. 2. Decreased pumping efficiency: A faulty seal can lead to reduced pumping efficiency. If you notice that the concrete pump is not delivering the expected amount of concrete or is struggling to pump the material, it could be due to a seal issue. 3. Increased noise and vibration: The operation of a concrete pump may experience heightened noise and vibration due to a defective seal. Unusual sounds or excessive vibration can indicate that the seal is not functioning properly, and further inspection may be necessary. 4. Premature wearing and tearing: A defective seal can cause premature wear and tear on other components within the pump system. This can be observed through the deterioration of other parts like gaskets, bearings, or pistons. Regular inspections can help identify such problems. 5. Inconsistent pressure: A faulty seal may result in inconsistent pressure while pumping concrete. If you notice pressure variations or irregular concrete flow, it may be a sign of a seal problem. 6. Excessive heat: Another indicator of a defective seal is the generation of excessive heat in the seal area. If the seal is not functioning properly, it can cause friction and heat buildup, which can be felt or observed by touch. Addressing any sign of a defective concrete pump seal promptly is crucial to prevent further damage to the pump system and ensure the operation's safety and efficiency. It is recommended to seek guidance and repair from a professional or contact the manufacturer in such cases.

- Q: Are there any specific guidelines for the installation of hopper components or agitators in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the installation of hopper components and agitators. These guidelines aim to ensure the equipment's proper functioning and safety. Here are some key guidelines to consider: 1. Manufacturer's instructions: Carefully read and understand the manufacturer's instructions for installing hopper components and agitators. These instructions provide specific details and steps for installation. 2. Use the right tools: Utilize appropriate tools and equipment as recommended by the manufacturer. This includes employing the correct size wrenches, bolts, and other necessary tools for the installation process. 3. Clean and level surface: Prior to installation, ensure the surface is both clean and level. This promotes proper alignment and functioning of the parts. 4. Check for damages or defects: Conduct a thorough inspection of the hopper components and agitators for any damages or defects prior to installation. If any issues are found, address them before proceeding with the installation. 5. Align and position correctly: Adhere to the manufacturer's recommendations for aligning and positioning the hopper components and agitators. Improper alignment may result in malfunctioning or premature wear of the parts. 6. Secure all connections: Ensure that all connections, such as bolts, nuts, and clamps, are securely fastened according to the manufacturer's instructions. Loose connections can lead to accidents or damage to the equipment. 7. Test the equipment: After installation, it is crucial to test the equipment to ensure proper functioning. Follow the manufacturer's guidelines for testing and make any necessary adjustments if required. 8. Regular maintenance and inspection: Once the hopper components and agitators are installed, it is vital to regularly inspect and maintain them. This includes cleaning, lubricating, and replacing any worn-out parts as recommended by the manufacturer. By adhering to these guidelines, you can ensure the correct installation of hopper components and agitators in concrete pump spare parts, promoting efficient operation and prolonging the equipment's lifespan.

- Q: Are there any specific guidelines for the disposal of packaging materials of concrete pump spare parts?

- Packaging materials of concrete pump spare parts have specific guidelines for disposal. It is advised to adhere to local waste management regulations and authorities' guidelines. To begin with, it is essential to separate the various packaging materials, such as cardboard boxes, plastic wraps, foam inserts, and other materials used for packaging the spare parts. This will facilitate efficient recycling or appropriate disposal of each material. Cardboard boxes can usually be recycled by flattening them and placing them in designated recycling bins. Plastic wraps should also be separated and discarded in specific plastic recycling bins. Foam inserts, commonly used for spare parts protection, may not be recyclable in all areas, so specific recycling instructions should be checked. If recycling is not possible, foam inserts can be disposed of in regular waste bins. Before disposal, it is important to ensure that all packaging materials are free from any residual concrete or other hazardous substances. Any contamination should be cleaned or removed properly to prevent environmental pollution. If the packaging materials cannot be recycled or disposed of through regular waste management methods, it is recommended to contact local recycling centers or waste management facilities to inquire about specific disposal options. They may offer guidance or accept these materials for specialized processing or disposal. Overall, responsible waste management practices should be prioritized, and compliance with local authorities' specific guidelines is crucial to ensure proper disposal of packaging materials for concrete pump spare parts.

- Q: How often should concrete pump pistons be replaced?

- The replacement frequency for concrete pump pistons depends on several factors, including usage, maintenance, and piston quality. It is generally advised to regularly inspect the pistons for signs of wear and tear, such as cracks, pitting, or scoring. If any of these signs are detected, it is recommended to replace the pistons immediately to prevent potential failures or leaks. Concrete pump pistons typically last between 25,000 and 75,000 cubic yards of pumped concrete, although this can vary depending on specific conditions and operating practices. For example, if the concrete being pumped contains abrasive materials or if the pump is used intensively or under harsh conditions, the pistons may wear out more quickly. Furthermore, proper maintenance practices can prolong the lifespan of the pistons. This includes regular cleaning and lubrication, maintaining the pump in good condition, and ensuring the pistons are correctly aligned and not subjected to excessive pressure or stress. In conclusion, closely monitoring the condition of the pistons and referring to the manufacturer's recommendations or seeking advice from a professional is essential to determine the appropriate replacement interval for the specific concrete pump being utilized.

- Q: What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

- Q: How can a faulty accumulator affect the pumping efficiency?

- A faulty accumulator can negatively impact pumping efficiency by causing inconsistent pressure and flow rates in the system. This can lead to excessive energy consumption, reduced overall performance, and potential damage to the pump and other components.

- Q: What are the different types of concrete pump hydraulic filters?

- There are several different types of concrete pump hydraulic filters that are commonly used in construction projects. These filters play a crucial role in ensuring the smooth operation and longevity of the hydraulic system in concrete pumps. 1. Suction filters: These filters are located at the intake side of the hydraulic pump and are responsible for removing larger particles and debris from the hydraulic oil. They prevent the pump from drawing in contaminants that can cause damage to the pump and other components. 2. Return line filters: Positioned on the return line of the hydraulic system, these filters are designed to remove smaller particles and contaminants from the hydraulic oil before it is returned to the reservoir. They help maintain the cleanliness of the hydraulic oil, preventing wear and tear on the system. 3. Pressure line filters: These filters are installed on the high-pressure side of the hydraulic system, typically after the hydraulic pump. They are responsible for removing fine particles and contaminants from the oil, ensuring the smooth operation of valves, cylinders, and other hydraulic components. 4. In-tank filters: These filters are submerged in the hydraulic oil reservoir and are used to filter the oil as it circulates through the tank. They are effective in removing larger particles and contaminants that may have settled at the bottom of the reservoir. 5. Magnetic filters: These filters utilize magnets to attract and remove metallic particles from the hydraulic oil. They are particularly effective in capturing ferrous contaminants, such as iron filings and metal shavings. 6. Breather filters: These filters are installed on the breather vent of the hydraulic oil reservoir. They prevent dust, dirt, and moisture from entering the system, maintaining the cleanliness and integrity of the hydraulic oil. It is important to regularly inspect and replace these hydraulic filters to ensure optimal performance and longevity of the concrete pump's hydraulic system. Failure to do so can result in increased wear and tear, decreased efficiency, and potential damage to the pump and other components.

- Q: What is the importance of a good quality concrete pump seal?

- There are several reasons why a high-quality concrete pump seal is of utmost importance. Firstly, it guarantees the efficient and dependable operation of the concrete pump. The seal's main responsibility is to prevent any leakage or loss of pressure during the pumping process, which can cause delays, inefficiencies, and even damage to the pump itself. Furthermore, a top-notch seal helps to maintain the integrity of the concrete being pumped. Concrete is composed of various materials, including water, cement, aggregates, and additives. To achieve the desired strength and durability, it is essential that the concrete remains in its optimal state without any contamination or dilution. A superior seal effectively blocks any external elements, such as water or air, from entering the pumping system and affecting the composition of the concrete. Moreover, a reliable seal contributes to the safety of the pumping operation. Construction sites often utilize concrete pumps, where workers and equipment are present. Any failure or malfunction of the seal can result in unexpected incidents, injuries, or damage to property. Therefore, investing in a high-quality seal provides peace of mind and reduces the risk of accidents. Lastly, investing in a top-quality concrete pump seal can lead to significant time and cost savings in the long run. A durable and efficient seal minimizes the need for frequent replacements or repairs, reducing maintenance costs and downtime. It also ensures a smooth and uninterrupted pumping process, allowing construction projects to be completed more efficiently and on schedule. In conclusion, prioritizing the selection and installation of a reliable concrete pump seal is crucial for ensuring the efficient operation, integrity of the concrete, safety, and cost-effectiveness of a pumping project. Therefore, it is essential to give utmost importance to choosing a high-quality seal to guarantee the success and longevity of concrete pumping projects.

Send your message to us

Elbow Reducer DN150-125 R250-90 Flange148MM-127MM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords